HPLC (high-performance liquid chromatography) is a powerful analytical technique used to separate and quantify a wide range of compounds. However, like any other analytical technique, HPLC systems can be susceptible to a variety of problems.

Here is a list of the most common 30 HPLC problems and solutions:

1. No peaks or very small peaks

There are a number of possible causes for no peaks or very small peaks in HPLC. Some of the most common include:

- Detector lamp off. Make sure that the detector lamp is turned on.

- Loose or broken wire between detector and integrator or recorder. Check all electrical connections and cables.

- No mobile phase flow. Make sure that the pump is turned on and that there is mobile phase in the reservoir.

- No sample/deteriorated sample/wrong sample. Make sure that there is sample in the sample loop and that it is not deteriorated or the wrong sample.

- Settings too high on detector or recorder. Reduce the detector sensitivity or recorder range.

If you have checked all of the above and are still not seeing peaks, you may need to troubleshoot the system further. This may involve flushing the column, degassing the mobile phase, or replacing the column.

Here are some additional tips for troubleshooting no peaks or very small peaks in HPLC:

- Check the mobile phase composition. Make sure that the mobile phase composition is correct for the sample you are trying to analyze.

- Check the column temperature. Make sure that the column temperature is correct for the sample you are trying to analyze.

- Check the flow rate. Make sure that the flow rate is correct for the column you are using.

- Check the sample injection volume. Make sure that the sample injection volume is not too large.

- Try a different mobile phase. If you are still not seeing peaks, try using a different mobile phase.

If you are still having problems, you may need to contact the manufacturer of your HPLC system for assistance.

2. High backpressure

High backpressure is one of the most common problems in HPLC. It can be caused by a number of factors, including:

- Clogged column. If the column is clogged, it will restrict the flow of mobile phase and cause the backpressure to increase.

- Blocked inlet filter. If the inlet filter is blocked, it will also restrict the flow of mobile phase and cause the backpressure to increase.

- Air bubbles in the mobile phase. Air bubbles in the mobile phase can create turbulence and increase the backpressure.

- Damaged pump seals. If the pump seals are damaged, they can leak and cause the backpressure to increase.

- Faulty check valve. If the check valve is faulty, it can allow mobile phase to flow backwards and increase the backpressure.

To troubleshoot high backpressure, you can try the following:

- Flush the column. Flush the column with a strong solvent to remove any clogs.

- Change the inlet filter. Replace the inlet filter if it is blocked.

- Degas the mobile phase. Degas the mobile phase to remove any air bubbles.

- Inspect the pump seals. If the pump seals are damaged, replace them.

- Inspect the check valve. If the check valve is faulty, replace it.

If you have tried all of the above and are still experiencing high backpressure, you may need to contact the manufacturer of your HPLC system for assistance.

Here are some additional tips for preventing high backpressure:

- Use high-quality solvents and mobile phase additives.

- Filter samples before injecting them into the HPLC system.

- Use a guard column to protect the analytical column.

- Flush the column regularly with a strong solvent.

- Follow the manufacturer’s instructions for maintaining your HPLC system.

3. Peak tailing

Peak tailing is another common problem in HPLC. It is caused by interactions between the sample and the stationary phase that are stronger than the desired interactions. This can happen for a number of reasons, including:

- Strong sample-column interactions. This can happen when the sample has a strong affinity for the stationary phase. For example, basic compounds can interact strongly with acidic silanol groups on silica-based columns.

- High mobile phase pH. This can deprotonate silanol groups on silica-based columns, making them more acidic and increasing the likelihood of strong sample-column interactions.

- Low mobile phase pH. This can protonate basic sample compounds, making them more likely to interact with acidic silanol groups on silica-based columns.

- Air bubbles in the mobile phase. Air bubbles can create turbulence and disrupt the flow of mobile phase, which can lead to peak tailing.

- Overloaded column. If the column is overloaded, the sample molecules will compete for binding sites on the stationary phase, which can lead to peak tailing.

- Column degradation. Over time, the stationary phase in the column can degrade, which can lead to peak tailing.

To troubleshoot peak tailing, you can try the following:

- Use a different mobile phase composition. Try using a mobile phase with a different pH or composition to reduce the likelihood of strong sample-column interactions.

- Degas the mobile phase. Remove any air bubbles from the mobile phase to prevent turbulence.

- Reduce the sample injection volume. If the column is overloaded, reduce the sample injection volume to improve peak shape.

- Replace the column. If the column is degraded, replace it to improve peak shape.

Here are some additional tips for preventing peak tailing:

- Use a high-quality column that is designed for the type of sample you are analyzing.

- Use a guard column to protect the analytical column.

- Flush the column regularly with a strong solvent to remove any contaminants.

- Follow the manufacturer’s instructions for maintaining your HPLC system.

If you are still having problems with peak tailing, you may need to contact the manufacturer of your HPLC system for assistance.

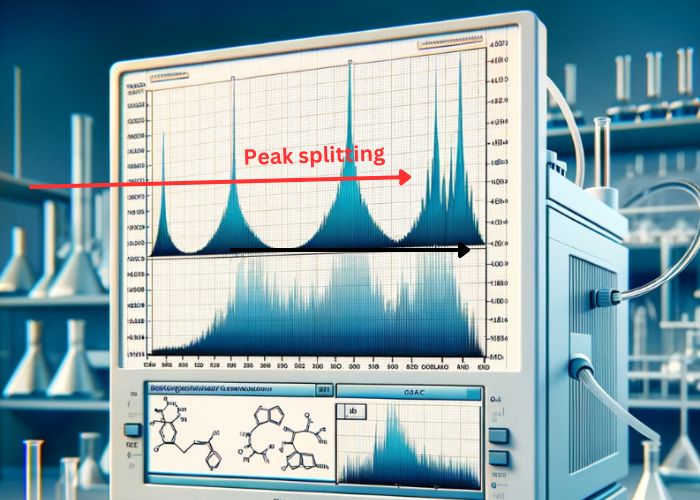

4. Peak splitting

Peak splitting is another common problem in HPLC. It is caused by the separation of a single peak into two or more peaks. This can happen for a number of reasons, including:

- Poor column packing. If the column is not packed properly, there may be voids in the stationary phase that can cause peak splitting.

- Incompatible mobile phase and sample solvents. If the mobile phase and sample solvents are not compatible, they can form micelles or aggregates that can cause peak splitting.

- Column overloading. If the column is overloaded, the sample molecules will compete for binding sites on the stationary phase, which can lead to peak splitting.

- Column degradation. Over time, the stationary phase in the column can degrade and become less homogeneous, which can lead to peak splitting.

To troubleshoot peak splitting, you can try the following:

- Repack the column. If the column is not packed properly, repack it following the manufacturer’s instructions.

- Use a different mobile phase or sample solvent. If the mobile phase and sample solvents are not compatible, try using different solvents.

- Reduce the sample injection volume. If the column is overloaded, reduce the sample injection volume to improve peak shape.

- Replace the column. If the column is degraded, replace it to improve peak shape.

Here are some additional tips for preventing peak splitting:

- Use a high-quality column that is designed for the type of sample you are analyzing.

- Use a guard column to protect the analytical column.

- Flush the column regularly with a strong solvent to remove any contaminants.

- Follow the manufacturer’s instructions for maintaining your HPLC system.

If you are still having problems with peak splitting, you may need to contact the manufacturer of your HPLC system for assistance.

5. Ghost peaks

Ghost peaks are unwanted peaks that appear in an HPLC chromatogram. They can be caused by a number of factors, including:

- Contaminated mobile phase. If the mobile phase is contaminated, it can cause ghost peaks. This can happen if the mobile phase is not filtered properly or if it is stored in a dirty container.

- Contaminated sample. If the sample is contaminated, it can also cause ghost peaks. This can happen if the sample is not prepared properly or if it is stored in a dirty container.

- Contaminated column. If the column is contaminated, it can also cause ghost peaks. This can happen if the column is not flushed properly after use or if it is stored improperly.

- Dirty detector. If the detector is dirty, it can also cause ghost peaks. This can happen if the detector is not cleaned properly after use.

To troubleshoot ghost peaks, you can try the following:

- Filter the mobile phase. Filter the mobile phase before use to remove any contaminants.

- Purify the sample. Purify the sample before injection to remove any contaminants.

- Flush the column. Flush the column with a strong solvent after use to remove any contaminants.

- Clean the detector. Clean the detector after use to remove any contaminants.

If you have tried all of the above and are still seeing ghost peaks, you may need to replace the column or the detector.

Here are some additional tips for preventing ghost peaks:

- Use high-quality solvents and mobile phase additives.

- Filter samples before injecting them into the HPLC system.

- Use a guard column to protect the analytical column.

- Flush the column regularly with a strong solvent.

- Clean the detector regularly.

- Follow the manufacturer’s instructions for maintaining your HPLC system.

If you are still having problems with ghost peaks, you may need to contact the manufacturer of your HPLC system for assistance.

Encountering ghost peaks in your HPLC analysis?

These mysterious, unexpected peaks can be puzzling and hinder accurate results. Understanding ghost peaks is crucial for reliable chromatography.

Check out uHPLCs’ specialized ‘Ghost Peaks Column‘ for expert insights and solutions to better manage and eliminate ghost peaks in your HPLC systems. Visit [uHPLCs website] for more information and take the first step towards clearer, more accurate chromatography results today!

6. Variable retention times

Variable retention times are another common problem in HPLC. They can be caused by a number of factors, including:

- Leaks. Leaks in the HPLC system can cause the mobile phase composition to change, which can lead to variable retention times.

- Changes in mobile phase composition. Changes in the mobile phase composition, such as pH or salt concentration, can also lead to variable retention times.

- Air trapped in pump. Air trapped in the pump can cause the flow rate of the mobile phase to fluctuate, which can lead to variable retention times.

- Column temperature fluctuations. Column temperature fluctuations can cause the retention times of compounds to change.

- Column overloading. Column overloading can also lead to variable retention times.

- Incompatible mobile phase and sample solvents. Incompatible mobile phase and sample solvents can cause the sample to precipitate or form micelles, which can lead to variable retention times.

To troubleshoot variable retention times, you can try the following:

- Check for leaks. Inspect the HPLC system for any leaks. If you find a leak, tighten the connection or replace the fitting.

- Use a consistent mobile phase composition. Make sure to use the same mobile phase composition for each run. This includes the pH, salt concentration, and solvent composition.

- Degas the mobile phase. Remove any air bubbles from the mobile phase before use.

- Control the column temperature. Use a column oven to control the column temperature and prevent fluctuations.

- Reduce the sample injection volume. If the column is overloaded, reduce the sample injection volume.

- Use compatible mobile phase and sample solvents. Make sure to use mobile phase and sample solvents that are compatible with each other.

If you have tried all of the above and are still experiencing variable retention times, you may need to contact the manufacturer of your HPLC system for assistance.

Here are some additional tips for preventing variable retention times:

- Use high-quality solvents and mobile phase additives.

- Filter samples before injecting them into the HPLC system.

- Use a guard column to protect the analytical column.

- Flush the column regularly with a strong solvent.

- Follow the manufacturer’s instructions for maintaining your HPLC system.

7. Drifting retention times

Drifting retention times are when the retention times of compounds change over time. This can happen for a number of reasons, including:

- Slow changes in mobile phase composition. Over time, the mobile phase composition can change due to evaporation, absorption, or contamination. This can lead to drifting retention times.

- Changes in column temperature. Changes in column temperature can also cause drifting retention times. This is because the retention times of compounds are temperature-dependent.

- Column degradation. Over time, the column can degrade, which can lead to drifting retention times. This is because the stationary phase in the column can become less homogeneous and/or less active.

To troubleshoot drifting retention times, you can try the following:

- Use a fresh mobile phase. Before each run, make sure to use a fresh mobile phase. This will help to prevent any changes in the mobile phase composition.

- Control the column temperature. Use a column oven to control the column temperature and prevent fluctuations.

- Replace the column. If the column is degraded, replace it to improve peak shape and reproducibility.

Here are some additional tips for preventing drifting retention times:

- Use high-quality solvents and mobile phase additives.

- Filter samples before injecting them into the HPLC system.

- Use a guard column to protect the analytical column.

- Flush the column regularly with a strong solvent.

- Follow the manufacturer’s instructions for maintaining your HPLC system.

If you are still having problems with drifting retention times, you may need to contact the manufacturer of your HPLC system for assistance.

In addition to the above, here are some other things you can do to minimize retention time drift:

- Use a system equilibration program. This will help to ensure that the column is completely equilibrated with the mobile phase before each run.

- Use a retention time standard. This is a compound with a known retention time that can be used to monitor for retention time drift.

- Use a data system that can track retention time drift and automatically correct for it.

If you are having difficulty troubleshooting drifting retention times, it is important to contact the manufacturer of your HPLC system for assistance.

8. Column-to-column and batch-to-batch reproducibility problems

Column-to-column and batch-to-batch reproducibility problems are a major challenge in HPLC analysis. They can be caused by a number of factors, including:

- Variations in column packing. If the column is not packed properly, there may be voids in the stationary phase that can affect reproducibility.

- Variations in mobile phase composition. If the mobile phase composition is not consistent, it can also affect reproducibility.

- Variations in sample preparation. If the sample is not prepared consistently, it can also affect reproducibility.

- Differences in column dimensions. If the column dimensions are not consistent, it can also affect reproducibility.

- Differences in column temperature. If the column temperature is not consistent, it can also affect reproducibility.

- Differences in detector sensitivity. If the detector sensitivity is not consistent, it can also affect reproducibility.

To improve column-to-column and batch-to-batch reproducibility, it is important to:

- Use columns from the same manufacturer and batch.

- Use a consistent mobile phase composition.

- Prepare samples consistently.

- Use columns with the same dimensions.

- Control the column temperature.

- Control the detector sensitivity.

In addition to the above, here are some other things you can do to improve column-to-column and batch-to-batch reproducibility:

- Use a guard column to protect the analytical column.

- Flush the column regularly with a strong solvent.

- Use a data system that can track retention time drift and automatically correct for it.

- Validate your HPLC method to ensure that it is reproducible.

If you are still having problems with column-to-column and batch-to-batch reproducibility, it is important to contact the manufacturer of your HPLC system for assistance.

Here are some additional tips for troubleshooting column-to-column and batch-to-batch reproducibility problems:

- Compare the column pressure and retention times of different columns. If there are significant differences, it may indicate a problem with the column packing.

- Check the mobile phase composition for consistency. You can use a pH meter or a conductivity meter to check the pH and conductivity of the mobile phase.

- Compare the sample preparation procedures for different samples. Make sure that the samples are prepared in the same way and that the same solvents and reagents are used.

- Check the column dimensions to make sure that they are consistent.

- Monitor the column temperature and make sure that it is consistent from run to run.

- Check the detector sensitivity to make sure that it is consistent from run to run.

If you have checked all of the above and are still having problems with column-to-column and batch-to-batch reproducibility, you may need to contact the manufacturer of your HPLC system for assistance.

9. Sample preparation problems

Sample preparation problems are a common source of errors in HPLC analysis. They can be caused by a number of factors, including:

- Incomplete sample dissolution. If the sample is not completely dissolved in the mobile phase, it can lead to peak tailing, ghost peaks, and other problems.

- Precipitation of sample components. If sample components precipitate out of the mobile phase, it can lead to clogged columns and other problems.

- Adsorption of sample components to sample vials or filters. If sample components adsorb to sample vials or filters, it can lead to reduced peak heights and other problems.

- Incorrect sample concentration. If the sample concentration is too high, it can lead to column overloading and other problems.

- Incorrect sample pH. If the sample pH is not compatible with the mobile phase pH, it can lead to peak tailing, ghost peaks, and other problems.

- Contamination of the sample. If the sample is contaminated, it can lead to ghost peaks and other problems.

To minimize sample preparation problems, it is important to:

- Use appropriate solvents to dissolve the sample completely.

- Filter the sample to remove any precipitated components.

- Use clean sample vials and filters to prevent adsorption of sample components.

- Use an appropriate sample concentration to avoid column overloading.

- Adjust the sample pH to match the mobile phase pH.

- Avoid contaminating the sample.

Here are some additional tips for troubleshooting sample preparation problems:

- If you are having problems with peak tailing, try using a different solvent to dissolve the sample or try filtering the sample.

- If you are having problems with ghost peaks, try using clean sample vials and filters or try filtering the sample.

- If you are having problems with reduced peak heights, try increasing the sample concentration or try using a different solvent to dissolve the sample.

- If you are having problems with clogged columns, try filtering the sample or try using a different solvent to dissolve the sample.

- If you are having problems with contamination, try using clean sample vials and filters or try filtering the sample.

If you are still having problems with sample preparation, it is important to contact the manufacturer of your HPLC system for assistance.

Here are some additional tips for good sample preparation practices:

- Use analytical grade solvents and reagents.

- Clean all glassware thoroughly before use.

- Use volumetric glassware to prepare accurate solutions.

- Label all samples and solutions clearly.

- Store samples and solutions properly.

By following these tips, you can minimize sample preparation problems and improve the accuracy and reproducibility of your HPLC results.

10. Sources of peak tailing

Peak tailing is a common problem in HPLC analysis. It can be caused by a number of factors, including:

- Strong sample-column interactions. This can happen when the sample has a strong affinity for the stationary phase. For example, basic compounds can interact strongly with acidic silanol groups on silica-based columns.

- High mobile phase pH. This can deprotonate silanol groups on silica-based columns, making them more acidic and increasing the likelihood of strong sample-column interactions.

- Low mobile phase pH. This can protonate basic sample compounds, making them more likely to interact with acidic silanol groups on silica-based columns.

- Air bubbles in the mobile phase. Air bubbles can create turbulence and disrupt the flow of mobile phase, which can lead to peak tailing.

- Overloaded column. If the column is overloaded, the sample molecules will compete for binding sites on the stationary phase, which can lead to peak tailing.

- Column degradation. Over time, the stationary phase in the column can degrade and become less homogeneous, which can lead to peak tailing.

- Incorrect mobile phase additives. Incorrect mobile phase additives can cause peak tailing by interacting with the sample or the stationary phase.

- Incorrect sample preparation. Incorrect sample preparation can cause peak tailing by introducing contaminants into the sample or by changing the sample pH.

To troubleshoot peak tailing, you can try the following:

- Use a different mobile phase composition. Try using a mobile phase with a different pH or composition to reduce the likelihood of strong sample-column interactions.

- Degas the mobile phase. Remove any air bubbles from the mobile phase to prevent turbulence.

- Reduce the sample injection volume. If the column is overloaded, reduce the sample injection volume to improve peak shape.

- Replace the column. If the column is degraded, replace it to improve peak shape.

- Use the correct mobile phase additives. Use mobile phase additives that are compatible with the sample and the stationary phase.

- Optimize sample preparation. Follow the manufacturer’s instructions for preparing the sample to avoid introducing contaminants or changing the sample pH.

If you have tried all of the above and are still experiencing peak tailing, you may need to contact the manufacturer of your HPLC system for assistance.

Here are some additional tips for preventing peak tailing:

- Use high-quality solvents and mobile phase additives.

- Filter samples before injecting them into the HPLC system.

- Use a guard column to protect the analytical column.

- Flush the column regularly with a strong solvent.

- Clean the detector regularly.

- Follow the manufacturer’s instructions for maintaining your HPLC system.

Contact us

Facing more other challenges with your HPLC systems? Reach out to the experts! Contact uHPLCs at sales@uhplcs.com and get personalized solutions for your top 10 HPLC problems. Let’s streamline your chromatography processes together!