HPLC Inlet Filter OEM Supplier

Home » HPLC Inlet Filter

10-Years HPLC Inlet Filter OEM Manufacturer

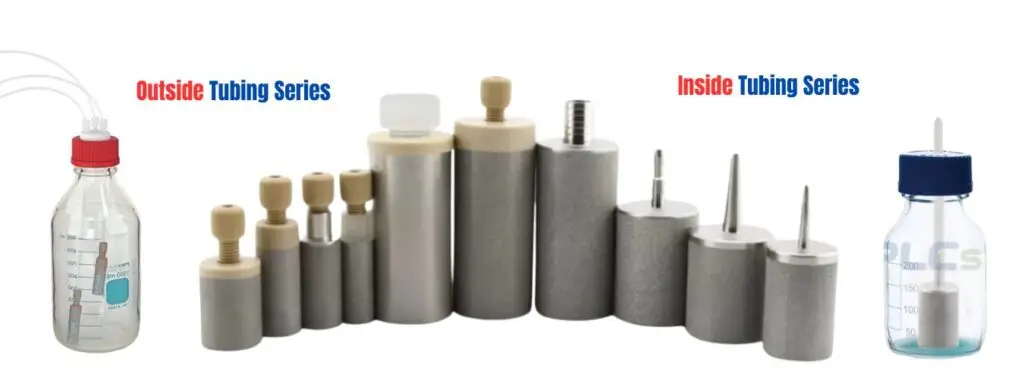

uHPLCs is a leading professional manufacturer and supplier of Solvent Inlet Filters, designed for High-Performance Liquid Chromatography (HPLC). With meticulous craftsmanship, our filters are created using premium 316L sintered stainless steel, ensuring the highest levels of quality and durability. We offer a diverse range of filter sizes for both inside and outside tubing to meet the specific needs of our customers.

Some Key Features of our HPLC Inlet Filter You Can Check As Following :

High-quality Material: Made from high-quality 316L sintered stainless steel, our solvent inlet filters are built to last, offering excellent resistance to corrosion and chemical damage.

Versatility: Available in a variety of sizes for both inside and outside tubing, our filters are adaptable to meet the requirements of different HPLC systems.

Exceptional Filtration: Engineered to offer superior filtration efficiency, our filters prevent particulates and contaminants from reaching critical HPLC components, enhancing the lifespan of your system and ensuring accurate and reproducible results.

Durable and Reliable: Our inlet filters are robustly designed to withstand the high pressures associated with HPLC operations, ensuring long-lasting and reliable performance.

Easy Maintenance: Designed with user convenience in mind, our filters are simple to clean and maintain, helping your laboratory operations run smoothly and efficiently.

OEM Solutions: As an OEM factory, we offer custom solutions to perfectly meet your specific needs and preferences.

- Large surface area and bubble-free filtration at the bottom.

- Many Pore Size Option: Available in 2μm, 5μm, 10μm, and 20μm inlet solvent filters.

Choosing uHPLCs’ HPLC Inlet Filter ensures the protection of your HPLC system and the accuracy of your analytical results.

Our commitment to quality, performance, and customer satisfaction makes us an ideal choice for laboratory and analytical professionals worldwide.

Our filters ensure reliable and efficient HPLC performance and are easy to install and maintain.

Our experienced team offers exceptional customer service and customizable solutions tailored to your needs.

Trust uHPLCs as your reliable supplier with 10 years of experience in providing top-quality products compatible with a wide range of solvents.

OD TUBING

HPLC

INLET FILTER

OD Series

Pore Size : 2μ,5μ,10μ,20μ

Tubing Size : 1 / 16″ ; 1 / 8″

Size: D9.5 * L33.0 ; D12. 7* L 28.5 ; D12.7 x L 32.2

Pore Size : 2μ,5μ,10μ,20μ

Tubing Size : 1 / 16″ ; 1 / 8″

Size: D9.5 * L33.0 ; D12. 7* L 28.5 ; D12.7 x L 32.2

Pore Size : 2μ,5μ,10μ,20μ

Tubing Size : 1 / 16″ ; 1 / 8″

Size: D12. 7 , OEM Size Available

Pore Size : 2μ,5μ,10μ,20μ

Tubing Size : 1 / 16″

Size: D12. 0 , OEM Size Available

Pore Size : 2μ,5μ,10μ,20μ

Tubing Size : 1 / 8″

Size: D12. 0 , OEM Size Available

ID TUBING

HPLC

INLET FILTER

ID Series

* Materials : 316L Stainless Steel

* Pore Size : 2μ,5μ,10μ,20μ

* Size Option

1) Option A

ID Size: 1.5-2.2-3

Size: D12. 7* L 28.5

2) Option B

ID Size: 2-2.5-3

Size: D12. 7* L 28.5 ; D19. 7* L 30.0

3) Option C

ID Size: 1.5-1/16“ ;2.2-3.0-1/8“ ; 3.5-Multi-stage Joint

Size: D12. 7* L 28.5 ;

4) Option D

ID Size: 1/8“-1/16“-3/16“ (3.0-4.0-5.0) -Multi-stage Joint

Size: D25* L 35 ;

Pore Size : 2μ,5μ,10μ,20μ

Tubing Size : 1.) 1 / 16″ – D10.0 * L19.5; D12.7 * L28.5; 2.) 1 / 8″ – D12.0 * L20.0; D16.0 * L32.0; 3.) 1 / 6″ – D25.0 * L52.7;

Pore Size : 2μ,5μ,10μ,20μ

Tubing Size : 1.) 1 / 16″ – D10.0 * L19.5; D12.7 * L28.5; 2.) 1 / 8″ – D12.0 * L20.0; D16.0 * L32.0; 3.) 1 / 6″ – D25.0 * L52.7;

Pore Size : 2μ,5μ,10μ,20μ

Tubing Size : 1.) 1 / 8″ – D12.7. * L28.5; D19.7 * L30.0; 2.) 3/ 16″ – D25.0 *L30.0; D25.0 * L40.0;

Pore Size : 2μ,5μ,10μ,20μ

Tubing Size : 1 / 8″

Size: D23.5* L5.4 OEM Size Available

What Do You Need for HPLC Solvent Inlet Filter?

Maximize the efficiency of your HPLC system with our high-quality solvent inlet filters – custom tailored to meet your specific needs.

Professional Team

We understand how important it is to have good first inlet filters in your HPLC system. Our team of experts make specifically designed filters to meet your needs. We listen to what you need and take into account important factors like flow rate and chemical compatibility. We use high-quality materials to make our filters. They are strong and will last a long time. They are easy to install and maintain so your system works as well as it can.

Enhancing HPLC Precision

The Expertise of Our Solvent Inlet Filter Team

Optimizing

Optimizing HPLC Performance with Our Professional Solvent Inlet Filter Team

Elevate Your HPLC Results

Meet Our Skilled Solvent Inlet Filter Specialists

Experienced R&D Team

We understand that different customers have different needs. That’s why we offer custom-designed solutions. Our R&D team can work with you to create filters that are specially designed for your HPLC System needs. Whether you need a filter for high flow rates or one that works with a specific type of solvent, we can help you find what you need. Our HPLC Solvent Inlet Filters are made following international safety standards and regulations to ensure they are of high quality.

Country Export

0

Production Area

0

Staff

0

Low MOQ

0

Production Time

0

Effective OEM Service

How to OEM HPLC Inlet Filter ?

- Research and development: Research the market and gather information on your customers’ specific needs and the industry’s current trends. It will help you to design a filter that is tailored to meet the needs of your customers.

- Design and prototyping: Use the information gathered during research and development to design and prototype the filter. That information will help you test the design and make necessary adjustments before mass production.

- Material procurement: Procure the high-quality materials required for producing the filter. It will ensure that the filter is of high quality and will perform well in the harsh conditions of an HPLC system.

- Manufacturing: Use the materials procured and the final design to manufacture the filter. Implementing strict quality control measures is important to ensure that each filter is manufactured to the highest quality standards.

- Packaging and branding: Package and brand the filter according to your company’s standards. The package will help build a good brand reputation and ensure customer satisfaction.

- Technical documentation and certification: Provide detailed technical documentation and certifications for each filter you produce. Certification will make it easy for your customers to ensure compliance with their quality standards.

- Compliance with international standards: Ensure your HPLC Solvent Inlet filters are manufactured in compliance with international standards and regulations. High-Quality standards will ensure that the product is safe and meets the highest quality standards.

- Marketing and Sales: Market and sell the filter to your target customers. Offer custom-designed solutions to meet your customers’ specific needs, which will help you stand out in the market and attract more customers.

- After-sales service: Provide good after-sales service to ensure customer satisfaction and help build a good reputation for your brand.

High Quality HPLC Column 316L, 316 Stainless Steel Tube Materials

Design New HPLC Columns 100% As Clients Request

Make HPLC Column Samples And Test Before Mass Products.

What Clients Say

We have been using the HPLC inlet filters from XYZ company for several years now and have never been disappointed. The filters are easy to install and maintain, and they have helped significantly improve our HPLC system's performance. Highly recommended!

Amanda LeeCEO

I have been extremely impressed with the custom-designed HPLC inlet solvent filter I purchased from ABC company. It has been tailored to meet my application's specific needs and has improved efficiency and accuracy in my analysis. I highly recommend ABC company to anyone needing a high-quality filter.

Adam CheiseDesigner

I have been using the HPLC inlet solvent filters from DEF company for over a year and have been extremely satisfied with their performance. The filters are made from high-quality materials and have helped significantly reduce my system's clogs. I highly recommend DEF company to anyone needing a reliable filter.

Floyd StallerCo-Founder

I recently purchased the HPLC inlet solvent filters from GHI company and have been impressed with their performance. The filters are easy to install and maintain, and they have helped to improve the overall efficiency and accuracy of my HPLC system. I would recommend GHI company to anyone needing a high-quality filter.

Floyd StallerCo-Founder

I had a great experience working with JKL company for my HPLC inlet solvent filter needs. They provided excellent customer service and were able to customize a filter that met the specific requirements of my application. The filter has worked great, and I am very happy with my purchase.

Floyd StallerCo-Founder

Previous

Next

Contact Salesman

High Quality HPLC Column 316L, 316 Stainless Steel Tube Materials

Design New HPLC Columns 100% As Clients Request

Make HPLC Column Samples And Test Before Mass Products.

HPLC Column FAQ & Applications

What is HPLC Inlet Filter ?

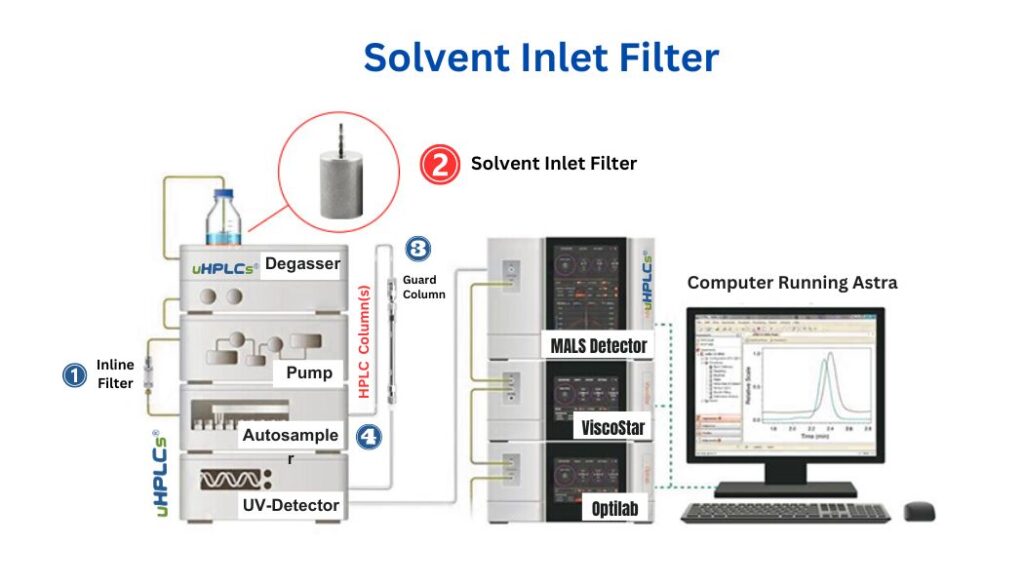

In High-Performance Liquid Chromatography (HPLC), a solvent inlet filter is a crucial component located at the entrance of the HPLC system, specifically at the point where the mobile phase (solvent) enters the instrument. Its primary purpose is to remove any particulate matter, debris, or impurities present in the solvent before it reaches the chromatographic columns and detector.

The solvent inlet filter is designed to protect the HPLC system from potential blockages or damage caused by particles that could be present in the solvent, which may arise from various sources such as contaminated solvents, dirty sample vials, or impurities in the mobile phase components. If these particles were to pass through the HPLC system, they could clog the narrow columns or harm sensitive detector components, leading to inaccurate or unreliable results.

By effectively trapping and removing these unwanted particles, the solvent inlet filter ensures smooth and reliable HPLC analyses, maintaining the integrity of the system and prolonging the lifespan of the columns and other components. Regular maintenance and replacement of the solvent inlet filter are essential to guarantee optimal performance and accurate results in HPLC analyses.

Types of HPLC Inlet Filter

There are several types of HPLC inlet filters available, each with its specific characteristics and applications. You Can Check Some common types as following :

Sintered Filters: These filters are made from porous materials such as stainless steel or ceramic. They are durable and can withstand high pressures, making them suitable for applications where the mobile phase may have particles of varying sizes.

Membrane Filters: These filters consist of a thin, porous membrane made of materials like polytetrafluoroethylene (PTFE) or nylon. They are effective at removing fine particulate matter and are often used for applications where a higher level of filtration is required.

Guard Column Cartridges: These are small, disposable cartridges filled with a filtering material. They are placed between the solvent reservoir and the HPLC system to protect the main columns and the system from impurities.

Disposable Inline Filters: These filters are typically made of stainless steel or PEEK (polyetheretherketone) and contain replaceable filter elements. They are easy to install and are commonly used to protect the HPLC system from contamination.

Glass Fiber Filters: These filters consist of fine glass fibers and are often used for filtering aggressive solvents or for specialized applications.

Frit Filters: These are small, porous discs made from materials like stainless steel or PEEK. They are commonly used in column end fittings to prevent particles from entering the column.

Actually, We also often distinguish HPLC Inlet Filter by tubing installation:

1. OD Tubing Suction Filter Head

2. ID Tubing Suction Filter Head

The choice of HPLC inlet filter depends on the specific requirements of the analysis, the nature of the mobile phase, and the type of sample being analyzed. Regular maintenance and replacement of the filter are essential to ensure optimal performance and prevent potential issues caused by contamination.

How HPLC Inlet Filter Cleaning ?

Cleaning the HPLC inlet filter is a crucial maintenance task that helps ensure the proper functioning of the system and accurate analytical results. The cleaning procedure depends on the type of filter used, but here are some general steps for cleaning an HPLC inlet filter:

Filter Removal: If the filter is a removable cartridge or frit, carefully remove it from the HPLC system. Follow the manufacturer’s guidelines or your organization’s standard operating procedures (SOPs) for safe removal.

Rinse with Solvent: Rinse the filter with an appropriate solvent (usually the same solvent used in your mobile phase) to remove any residual sample or contaminants. This step helps prevent cross-contamination between different samples.

Ultrasonic Bath (Optional): If the filter is heavily contaminated or clogged, you may use an ultrasonic bath. Place the filter in a suitable container filled with a cleaning solvent and subject it to ultrasonic vibrations. This helps dislodge stubborn particles from the filter’s surface.

Backflushing (If Applicable): For some filters, such as guard column cartridges, you may be able to backflush the filter. This involves reversing the flow of solvent through the filter to dislodge and remove trapped particles.

Drying: After cleaning, allow the filter to dry completely. You can use a stream of filtered air or a gentle flow of nitrogen to speed up the drying process. Ensure the filter is completely dry before reinstallation.

Inspect for Damage: While the filter is removed, inspect it for any signs of damage, such as cracks, tears, or degradation. If you notice any issues, replace the filter with a new one.

Reinstallation: Once the filter is clean and dry, carefully reinstall it into the HPLC system according to the manufacturer’s instructions or your organization’s SOPs.

System Check: After cleaning and reinstallation, perform a system check and run a blank analysis (solvent without any sample) to ensure that the HPLC system is functioning correctly and that no contaminants remain in the system.

It’s essential to follow the HPLC instrument manufacturer’s guidelines and any specific cleaning recommendations for the type of inlet filter you are using. Regular and proper cleaning of the inlet filter helps maintain the system’s performance, prolongs the life of columns and detectors, and ensures reliable and reproducible analytical results.

Main Materials for HPLC Inlet Filter ?

Sintered stainless steel has become the main material for HPLC inlet filters due to several advantageous properties that make it ideal for this application:

Chemical Compatibility: Stainless steel is highly resistant to corrosion and chemical reactions with a wide range of solvents and mobile phase components commonly used in HPLC. This chemical compatibility ensures that the filter material does not degrade or contaminate the mobile phase or samples during the filtration process.

Mechanical Strength: Sintered stainless steel filters are mechanically robust and can withstand high pressure in the HPLC system without breaking or deforming. This strength is crucial as HPLC systems typically operate at high pressures, and the filter must endure these conditions without failure.

Temperature Resistance: HPLC systems often operate at elevated temperatures, especially in applications involving high-temperature chromatography. Sintered stainless steel filters can withstand these elevated temperatures without losing their integrity or filtration efficiency.

Uniform Pore Size Distribution: The sintering process allows for precise control over the pore size distribution of the stainless steel filter. This uniformity ensures consistent filtration performance and prevents the passage of particles of undesired sizes.

Longevity and Reusability: Sintered stainless steel filters have a long lifespan and can be cleaned and reused multiple times, making them a cost-effective choice for HPLC applications.

Minimal Adsorption: Stainless steel is relatively inert and exhibits minimal adsorption of analytes or other sample components passing through the filter. This characteristic is essential to avoid any loss or alteration of the sample during the filtration process.

Ease of Cleaning: Stainless steel filters can be easily cleaned and restored to their original condition. This enables efficient maintenance of the HPLC system, reducing downtime and the need for frequent filter replacements.

Wide Range of Applications: Sintered stainless steel filters are versatile and can be used with a variety of solvents and sample types, making them suitable for a broad range of HPLC analyses.

For these reasons, sintered stainless steel has become the material of choice for HPLC inlet filters in many laboratories and industrial settings. It provides reliable and consistent performance, contributing to the overall accuracy and reproducibility of HPLC analyses.

Factors You Should Care When Choose HPLC Inlet Filter ?

When choosing an HPLC solvent inlet filter, several factors you should be carefully considered to ensure optimal performance and compatibility with the HPLC system. Here are the key factors to keep in mind:

Chemical Compatibility: Ensure that the filter material is chemically compatible with the solvents and mobile phase components used in your HPLC analysis. Stainless steel and PEEK (polyetheretherketone) are commonly used materials that offer good chemical resistance.

Filtration Efficiency: Consider the pore size of the filter material. The filter should be capable of removing particles and impurities from the mobile phase without causing excessive pressure drop in the system.

Pressure Rating: Check the filter’s pressure rating to ensure it can withstand the operating pressure of your HPLC system without failure or clogging. Higher pressure ratings are desirable for high-pressure HPLC systems.

Sample Compatibility: If your samples contain aggressive or particulate-rich solvents, choose a filter that can handle these conditions without degradation or clogging.

Flow Rate: The filter should allow the required flow rate for your specific HPLC application without introducing significant backpressure.

Physical Size: Ensure that the filter’s dimensions are compatible with your HPLC system. It should fit securely without impeding the flow path.

Temperature Resistance: Consider the temperature range at which your HPLC system operates. The filter material should be able to withstand these temperatures without any adverse effects on its integrity or filtration performance.

Backpressure: Minimize the impact of the filter on the overall backpressure in your HPLC system. Excessive backpressure can affect the system’s efficiency and may lead to column degradation.

Replaceability: Some filters are disposable and need replacement after use, while others are reusable and can be cleaned. Consider your laboratory’s preference and cost-effectiveness when choosing between disposable and reusable filters.

Manufacturer’s Recommendations: Follow the recommendations of the HPLC instrument manufacturer regarding the type and specifications of the inlet filter suitable for your specific HPLC system.

Guard Columns: If you use guard columns to protect your analytical columns, ensure that the filter complements the guard column effectively, preventing particles from reaching the main column.

Application-Specific Filters: For specialized applications, such as the analysis of highly sensitive samples or aggressive solvents, there might be specific filters designed for these purposes. Consider using filters tailored to your unique requirements.

Regulatory Compliance: If your laboratory or industry operates under specific regulations, ensure that the selected filter meets the necessary compliance standards.

By carefully evaluating these factors, you can choose an HPLC solvent inlet filter that best suits your needs, promotes the longevity of your HPLC system, and ensures reliable and accurate analytical results.

Why OEM HPLC Inlet Filter From uHPLCs ?

If you are looking for a manufacturer to OEM Special HPLC solvent inlet filter, Then You Find the right place, becase uHPLCs is one of best porous metal filter manufacturer and you can check Details about OEM service, and here we list some reasons why choose us:

Expertise and Specialization: uHPLC manufacturers have expertise and specialization in high-pressure liquid chromatography systems, and their solvent inlet filters are likely designed to meet the stringent requirements of uHPLCs, such as higher pressure ratings and finer filtration capabilities.

Compatibility: An HPLC solvent inlet filter from an OEM specializing in uHPLCs is likely to be fully compatible with their specific uHPLC models. This ensures a seamless fit and optimal performance within the uHPLC system.

Quality and Reliability: uHPLC manufacturers are committed to maintaining high-quality standards for their products. Using their OEM solvent inlet filters can ensure reliability and consistent performance within the uHPLC system.

Customization and Optimization: uHPLC OEMs might offer customization options for their solvent inlet filters to meet specific analytical needs or applications, optimizing the filtration performance for their high-pressure systems.

Long-Term Support: By choosing an OEM solvent inlet filter from a uHPLC manufacturer, you can expect reliable long-term support and access to technical assistance from the same company that designed the uHPLC system.

Seamless Integration: Using an OEM solvent inlet filter from the same manufacturer as the uHPLC system can lead to better integration and coordination between the components, potentially enhancing overall system performance.

It’s important to note that while OEM Inlet filters from uHPLC manufacturers may offer advantages in uHPLC applications, there are also high-quality solvent inlet filters available from reputable third-party suppliers that can be suitable for various HPLC systems, including both conventional HPLCs and uHPLCs. When choosing an HPLC solvent inlet filter, consider factors such as compatibility, filtration efficiency, chemical resistance, and overall performance to ensure the best fit for your specific HPLC application.

HPLC Inlet Filter Applications

HPLC Inlet Filters are utilized in a variety of fields and applications due to their vital role in maintaining the purity of the system solvent and ensuring accurate, repeatable analytical results. Here are some of the major applications:

Pharmaceutical Industry: HPLC inlet filters are extensively used in pharmaceutical research and manufacturing processes to ensure the purity of raw materials, to monitor production processes, and to perform quality control on finished products.

Biotechnological Applications: These filters are critical for separating and analyzing complex biological samples, such as proteins, peptides, DNA, and more, ensuring they are free of particulate matter and contaminants.

Environmental Testing: HPLC inlet filters are used for the precise analysis of environmental samples to detect pollutants or contaminants. Their filtration capacity is crucial for accurate and reliable measurements.

Food and Beverage Analysis: These filters are instrumental in detecting and quantifying additives, contaminants, and natural components in food and beverage samples.

Clinical Diagnostics: In clinical and diagnostic settings, HPLC inlet filters are used to analyze bodily fluids for the presence of specific compounds or biomarkers.

Chemical Industry: They are vital in the chemical industry for purity checks, reaction monitoring, and quality control, ensuring a clean, uninterrupted flow of solvent into the HPLC system.

Academic Research: In research settings, these filters play a crucial role in various studies involving chemical separation, identification, and quantification.

In all these applications, HPLC Inlet Filters from uHPLCs will ensure high-quality, accurate results by effectively removing particulates and contaminants from the solvent entering the HPLC system.

Frequently Asked Questions

Do You Have Some Questions About HPLC Inlet Filter For Your HPLC System ? Check Questions As Follow:

HPLC inlet filters are used to filter impurities from the solvent before it enters the HPLC system. It helps to ensure that the system is running at peak performance and that the analysis results are accurate.

It is important to use a solvent inlet filter for HPLC because impurities in the solvent can cause clogs in the system, leading to reduced performance and inaccurate results. Using a solvent inlet filter helps remove impurities before they can enter the system, ensuring that the system runs at peak performance at all times.

HPLC inlet solvent filters are typically made from high-quality materials such as stainless steel, PTFE, or PVDF. These materials are designed to withstand the harsh conditions of an HPLC system and provide long-lasting performance.

The frequency of replacement will depend on the specific application and the type of filter being used. It is generally recommended to replace the filter when a noticeable performance drop is observed, or the filter becomes clogged.

Yes, You can clean Some HPLC inlet solvent filters, but it is best to consult the manufacturer’s instructions for specific cleaning instructions. In general, you’d better only clean if the manufacturer recommends and with a solution compatible with the filter material.

Custom-designed HPLC inlet solvent filters are tailored to meet the customer’s specific needs. It can result in improved performance and efficiency and increased filter longevity.

A properly working HPLC inlet solvent filter will have minimal pressure drop and will not become clogged quickly. If you notice a significant drop in performance or a clogged filter, it may be time to replace it.

Not all HPLC inlet solvent filters are suitable for use with all types of solvents. It is important to consult the manufacturer’s instructions to ensure that the filter is compatible with the specific solvent used.

Installation instructions will vary depending on the specific filter being used. It is best to consult the manufacturer’s instructions for specific installation instructions.

You can contact uHPLCs for HPLC inlet solvent filters, and we supply a variety of designs and sizes of HPLC inlet filters, including online retailers and laboratory supply companies. Choosing a reputable supplier that provides high-quality filters and good customer service is important.

Need Help ?

Contact uHPLCs Today for Any Questions for HPLC / UHPLC

+(86) 0755-28502380

sales@uhplcs.com

Contact Us

Recent Posts

Types of HPLC Solvent Filters and How to Choose

Introduction In High Performance Liquid Chromatography (HPLC), the purity of solvents is paramount for achieving

HPLC Prep HPLC Columns Full Guide

High-performance liquid chromatography (HPLC) is a workhorse technique in labs worldwide, separating complex mixtures into

Normal vs Reverse Phase Chromatography Column 101

Introduction to Normal and Reverse Phase Chromatography Columns In High-Performance Liquid Chromatography (HPLC), the choice

Table of Contents

Hotsale HPLC Products

c18 hplc column 4.6 and 250mm

Previous slide Next slide USHD C18-Pro 5 µm 4.6 x 250 mm Unlock unparalleled robustness with the USHD C18-Pro HPLC column, where superior chemical resistance

50mm Empty HPLC Columns

Previous slide Next slide 50mm Empty HPLC Columns Wholesale and OEM Manufacturer Short Description: UHPLC Empty Column Hardware (Each column blank kit) includes a precision-bore

20mm Empty HPLC Columns

Previous slide Next slide 20mm Empty HPLC Columns 316L Stainless Steel Short Description: UHPLC Empty Column Hardware (Each column blank kit) includes a precision-bore polished

10mm Empty HPLC Columns

Previous slide Next slide 10mm Empty HPLC Columns 316L Stainless Steel Short Description: UHPLC Empty Column Hardware (Each column blank kit) includes a precision-bore polished

4.6mm Empty HPLC Columns 316L Stainless Steel

Previous slide Next slide 4.6mm Empty HPLC Columns 316L Stainless Steel Short Description: UHPLC Empty Column Hardware (Each column blank kit) includes a precision-bore polished

7.8mm Semi-prepared Empty HPLC Columns

Previous slide Next slide 7.8mm Semi-prepared Empty HPLC Columns HPLC Column Assembly, Empty, 150 mm/250/300 L x 7.8 mm ID x 1/4″ OD Short Description: