Improve separations with precise columns.

Home » HPLC Column Packing Material

HPLC Column Packing Material

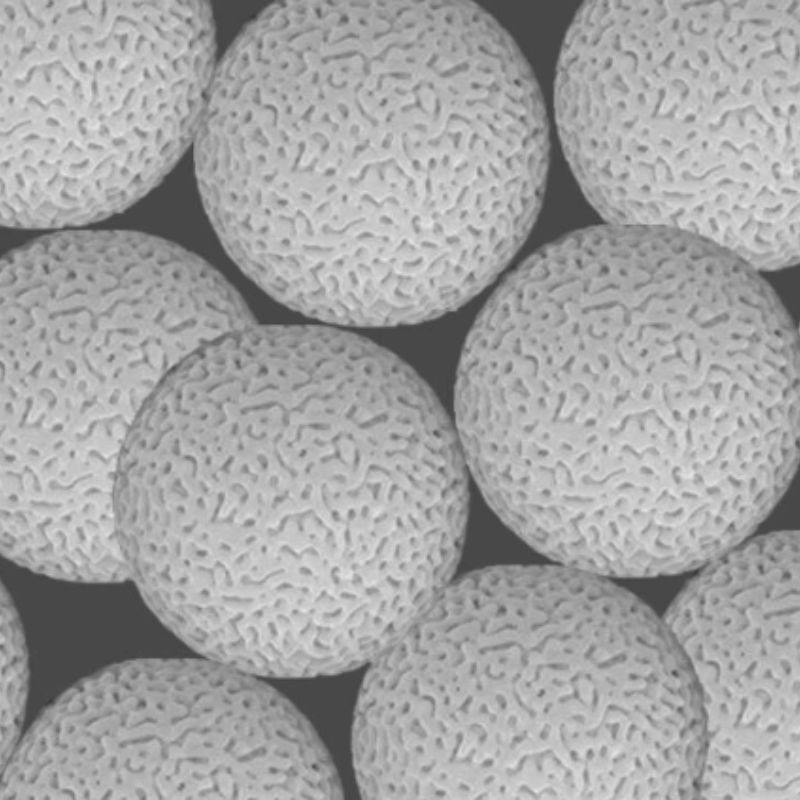

Silica gel is the most widely uesd subdrate for Liquid Chromatography stationary phases. Its physical and chemical properties make it suitable for a wide variety of analytical and preparative separations.

Average particle size

1.8um、2um, 3um、5um、10um 20um、30umand more larger particle

Bonded Phase

C18、C、C4、C18-BIOC18-T、C18-AQ、PhenylNH2、CN、Diol、SiL

Sealing Assembly

HE Standard SealUn-Sealed

Average Pore Size

70um、100um120um、200um、300um

HPLC ANALYTICAL GRADES

Super Pure Spherical silica product line is dedicated to analytical HPLC and UHPLC where high efficiency and high mechanical strength is required.

READ MORE

HPLC SEMI-PREPARATIVE & FLASH GRADES

Flash chromatographt is a quick and easy way to separate complex mixtures of compounds. The silica gel is specifically designed to increase cartridge efficiency while exhibiting moderate back-pressure; and therefore improving resolution.

READ MORE

PREPARATIVE & FLASH GRADES

The silica gel is fully dedicated to preparative HPLC. The SMB line offers significant advantages including easy packing, high efficiency, and high capacity, thus offering economic advantages for large-scale processes.

READ MORE

INDUSTRIAL LC GRADES

Industrial Liquid Chromatography plays an essential role in many industrial sectors, this technique is uesd in the chemical, agrochemical, cosmetic, veterinary, pharmaceutical, etc., to purify natural extracts, organic intermediates, drug substances,etc...

READ MORE

Contact Us For Excellent Service

Features & Benefits

> SPS purity SiO2 is higher than 99.99%

> Selection of particle sizes to optimize efficiency

> Tight distribution of particle sizes and spherical particle shape to reducr back-pressure

> Lot-to-Lot consistency for reproducible performance

> Superior pressure strength

> Consistent and reproducible retention times to allow direct scale-up from laboratory through process applications

> Large bulk quantities for all applications available, secutrd lots offered for process use

What Clients Say

I have been using uHPLC columns packed with the latest packing materials from uHPLCs for my research for the past few months, and the results have been outstanding. The separation efficiency and resolution of the columns are incredible, making it easier for me to identify and quantify target analytes in my samples.

Amanda LeeCEO

The uHPLC column packing materials from uHPLCs have greatly improved the sensitivity and accuracy of my analytical assays. The columns have a low dead volume, which reduces peak tailing and increases signal-to-noise ratio. Overall, I am extremely satisfied with the performance of these columns.

Adam CheiseDesigner

I have been in the analytical chemistry field for over 20 years, and I can confidently say that the uHPLC column packing materials from uHPLCs are some of the best I have ever used. The columns have a high efficiency and excellent reproducibility, which is crucial for producing reliable data.

Floyd StallerCo-Founder

As a graduate student, I have been using uHPLC columns packed with uHPLCs packing material for my thesis project, and I have been impressed with the consistent results I have obtained. The columns have a long lifespan, and I have been able to use them for multiple analyses without seeing any significant deterioration in performance.

Floyd StallerCo-Founder

I would highly recommend the uHPLC column packing materials from uHPLCs to anyone in the analytical chemistry field. The columns are easy to use and produce reliable and reproducible results, making them an essential tool for any researcher looking to improve their analytical assays.

Floyd StallerCo-Founder

Previous

Next

HPLC Column FAQ

Applications of HPLC Column Packing Material

HPLC column packing material is used in a wide range of applications in various industries, including pharmaceuticals, biotechnology, environmental testing, food and beverage analysis, and more. Here are some specific applications of HPLC column packing material:

Pharmaceutical industry: HPLC column packing material is used to separate and purify active pharmaceutical ingredients (APIs) and their impurities. This is crucial for ensuring the quality, safety, and efficacy of drugs.

Biotechnology industry: HPLC column packing material is used for protein and peptide purification. It can separate proteins and peptides based on their size, charge, and hydrophobicity.

Environmental testing: HPLC column packing material is used to analyze environmental samples such as water, soil, and air for the presence of pollutants and contaminants. It can separate and quantify a wide range of compounds, including pesticides, herbicides, and heavy metals.

Food and beverage analysis: HPLC column packing material is used to analyze food and beverage samples for the presence of additives, preservatives, and contaminants. It can also be used to quantify nutrients such as vitamins and amino acids.

Forensic science: HPLC column packing material is used for drug testing and toxicology analysis. It can separate and quantify drugs and their metabolites in biological samples such as blood, urine, and saliva.

Overall, HPLC column packing material plays a critical role in various analytical applications by providing high separation efficiency, reproducibility, and selectivity.

Frequently Asked Questions

Here are some questions about HPLC Column Packing and Materials, Do you Have Any Other Questions for HPLC system? You are Welcome to Contact us by email for more details .

HPLC column packing material is a stationary phase material that is packed into a chromatography column to separate and purify different compounds from a mixture. The packing material is typically made up of small particles that are packed tightly into the column to maximize the separation efficiency.

High-Performance Liquid Chromatography (HPLC) is a widely-used analytical technique in chemistry and biochemistry. One of the most critical components of an HPLC system is the column, and the packing material inside the column plays a crucial role in the separation process. Here are some of the common types of HPLC column packing materials:

Silica-based packings:

- Normal phase: Made primarily of bare silica. It’s used in non-aqueous mobile phases and is often applied for the separation of compounds based on polarity.

- Reversed phase: Silica particles modified with hydrophobic groups such as C8 or C18. This is the most common type of HPLC column, used in combination with aqueous mobile phases.

Polymer-based packings:

- Used when pH extremes are required since they offer more stability than silica-based packings at either very high or very low pH.

Ion-exchange packings:

- Used for separating ions and polar molecules based on charge. Can be:

- Cation exchange (for positive ions)

- Anion exchange (for negative ions)

- Used for separating ions and polar molecules based on charge. Can be:

Size exclusion or gel filtration packings:

- Used for separating molecules based on size. They are commonly employed in protein and polymer analysis.

Chiral packings:

- Designed for the separation of enantiomers (mirror-image isomers). They can be made of either silica or polymer materials with chiral selectors bonded to their surfaces.

Affinity packings:

- Coated with ligands that can specifically bind to target molecules. This provides a highly selective separation based on a specific binding interaction.

Hydrophilic Interaction Liquid Chromatography (HILIC) packings:

- These are polar columns that are primarily used for separating polar compounds. In HILIC, a polar stationary phase and a comparatively less polar mobile phase (usually acetonitrile with water) are used.

Mixed-mode packings:

- These combine two or more types of interactions, such as reversed phase and ion exchange, to offer unique separation mechanisms.

Specialty packings:

- These are designed for specific applications, such as the separation of nucleic acids or carbohydrates.

When choosing a column packing material for HPLC, it’s essential to consider the nature of the sample, the separation mechanism required, and the pH and temperature stability of the packing material. Properly selecting the right packing material can significantly influence the efficiency, selectivity, and resolution of the separation.

The choice of HPLC column packing material depends on the specific application and the compounds that need to be separated. Factors such as polarity, size, and chemical structure of the compounds should be considered when selecting the packing material.

HPLC column packing materials are designed to withstand high pressures and typically have a maximum pressure rating of up to 400 bar (5800 psi).

To pack an HPLC column with packing material, the column is first filled with a slurry of the packing material in a suitable solvent. The slurry is then allowed to settle, and the excess solvent is drained off. The column is then packed by applying pressure to the slurry to compact the packing material.

The frequency of replacing the packing material in an HPLC column depends on several factors. There isn’t a one-size-fits-all answer because the longevity of the column can be influenced by the type of samples you run, how you maintain the system, the specific type of column, and the conditions under which it’s used. Here are some considerations to guide you:

Column Performance: Regularly monitor the column’s performance. If you start noticing decreased efficiency, peak tailing, or a change in the retention time of standard compounds, it might indicate that the column is deteriorating.

Pressure: A significant increase in backpressure might be an indication that the column is clogged or the packing material is deteriorating. Sometimes, a simple column wash can resolve this, but if the problem persists, it might be time to consider repacking or replacing the column.

Nature of Samples: Columns that are used with dirty or complex samples will wear out faster than those used with clean samples. Using guard columns can help prolong the life of the main column by capturing contaminants.

Usage Frequency: A column that’s used occasionally and stored properly in between uses can last longer than a column that’s in constant use.

Cleaning and Regeneration: Regular column cleaning and regeneration can extend its life. However, overly aggressive cleaning or using unsuitable solvents can reduce the column’s lifespan.

Operational Conditions: Running the column outside its recommended pH range, temperature range, or pressure can shorten its life.

Age: Even if a column isn’t used frequently, the bonded phase can degrade over time. Therefore, an old column that’s been sitting unused for a long time might not perform as well as a new one.

As a general guideline:

Analytical Columns: With proper care, they can last for hundreds of injections. Some might even last for over a thousand injections. Monitoring performance is crucial.

Preparative Columns: Due to the larger sample loads, these columns might require more frequent repacking, especially if the sample matrix is complex or if there’s a high risk of contamination.

Rather than adhering to a strict replacement schedule, it’s best to regularly monitor your column’s performance and use the signs of deterioration as a guide. If you find you’re frequently replacing or repacking columns, consider troubleshooting your HPLC system, reviewing your sample preparation methods, or consulting with the column manufacturer for guidance.

Common problems associated with HPLC column packing material include poor column efficiency, loss of resolution, and column blockage. These problems can be caused by factors such as poor packing, incorrect particle size or composition, and column overloading. Regular column maintenance and proper packing techniques can help prevent these issues.

Need Help ?

Contact uHPLCs Today for Any Questions for HPLC / UHPLC

+(86) 0755-28502380

sales@uhplcs.com

Contact Us

Recent Posts

Types of HPLC Solvent Filters and How to Choose

Introduction In High Performance Liquid Chromatography (HPLC), the purity of solvents is paramount for achieving

HPLC Prep HPLC Columns Full Guide

High-performance liquid chromatography (HPLC) is a workhorse technique in labs worldwide, separating complex mixtures into

Hotsale HPLC Products

c18 hplc column 4.6 and 250mm

Previous slide Next slide USHD C18-Pro 5 µm 4.6 x 250 mm Unlock unparalleled robustness with the USHD C18-Pro HPLC column, where superior chemical resistance

50mm Empty HPLC Columns

Previous slide Next slide 50mm Empty HPLC Columns Wholesale and OEM Manufacturer Short Description: UHPLC Empty Column Hardware (Each column blank kit) includes a precision-bore

20mm Empty HPLC Columns

Previous slide Next slide 20mm Empty HPLC Columns 316L Stainless Steel Short Description: UHPLC Empty Column Hardware (Each column blank kit) includes a precision-bore polished