Porous Metal Flow Restrictors

Home » Gas Flow Restrictor

Porous Metal Gas Flow Restrictor OEM Supplier

uHPLCs is a leading OEM supplier of porous metal gas flow restrictor elements. Our products are designed to provide precise control over gas flow, making them ideal for various applications, including high-performance liquid chromatography (HPLC), ultra-high-performance liquid chromatography (uHPLC), and mass spectrometry. Our products are made from high-quality materials, ensuring they are durable, reliable, and long-lasting.

One of the key benefits of our metal porous gas flow restrictor elements is their precise control over the gas flow. It is achieved through advanced materials and manufacturing techniques, which allow for the creation of precise micro-scale orifices that can be adjusted with great accuracy. This results in a level of control over gas flow that is unparalleled by other suppliers in the industry.

In addition to our precise control over gas flow, uHPLCs’ products are also designed to be highly efficient. It is achieved through low-resistance orifices, allowing high-speed, high-resolution analysis. The company’s products are also designed to be low maintenance, with long-lasting performance that reduces the need for frequent replacements.

Gas Flow Restrictors For Healthcare And Lifesciences

Fluid Flow Restrictors For HPLC System

Stainless Steel Filter Orifice Insert Threaded For Gas Chromatograp

Fluid Flow Restrictors For HPLC _ GC Flow Controllers

Flow Restrictor Fitting _ Adjustable Gas Flow Inse For Flow Control

Inlet and Outlet SST Check Valves Tested For GC Pumps

Inlet and Outlet Flow Restrictors For GC Pumps

High Purity Fluid Flow Restrictor Valve For GC

Flow Restrictors For GC Pressure Relief Valve

To ensure that our Metal Porous Gas Flow Restrictor meet your higher quality standards, uHPLCs employs a team of highly skilled engineers and technicians. These individuals work closely with customers to understand their specific needs and requirements and design and manufacture products that meet them. They also continuously test and evaluate their products to ensure they perform to the highest standards, providing customers with peace of mind knowing they are getting the best possible products.

Overall, uHPLCs is a leading OEM supplier of gas flow restrictor elements, providing precise control over gas flow, high efficiency, and low maintenance. Their products are designed to meet the needs of a wide range of applications, including HPLC, uHPLC, and mass spectrometry. They are made from high-quality materials to ensure they are reliable, durable, and long-lasting. If you need a high-quality gas flow restrictor element for your application, look no further than uHPLCs.

What kind of Gas You Need to Deal

Unlock Maximum Efficiency with Our Gas Flow Restrictor! This innovative device accurately regulates the gas flow, ensuring optimal performance and minimizing waste. Don’t settle for less – upgrade to the best gas flow solution today!

Advantage of uHPLCs Gas Flow Restrictor

Ultra-high-performance liquid chromatography (uHPLC) systems incorporating a gas flow restrictor have become increasingly popular in the field of chromatography due to their many benefits. Here are some key reasons why working with uHPLCs for gas flow restrictors is advantageous:

- Increased resolution: The smaller particle size and narrow bore columns used in uHPLCs allow for improved separation of complex sample mixtures, leading to increased resolution.

- Improved efficiency: The high-pressure pumping system in uHPLCs enables faster and more efficient separations than traditional HPLCs.

- Reduced analysis time: uHPLCs typically require less sample and take less time to run a separation, leading to reduced analysis time.

- Increased sensitivity: The small particle size and narrow bore columns in uHPLCs improve sensitivity, allowing for detecting trace amounts of analytes in a sample.

- Better control of pressure and flow rate: Using a gas flow restrictor in uHPLCs enables precise control of pressure and flow rate, leading to improved accuracy and reproducibility of results.

- Reduced solvent consumption: uHPLCs typically use less solvent than traditional HPLCs, resulting in cost savings and reduced environmental impact.

In conclusion, uHPLCs that utilizes a gas flow restrictor provide many advantages over traditional HPLC systems, including improved resolution, increased efficiency, reduced analysis time, increased sensitivity, better control of pressure and flow rate, and reduced solvent consumption.

Country Export

0

Production Area

0

Staff

0

Low MOQ

0

Production Time

0

OEM Gas Flow Limiter

When customizing a gas flow restrictor or gas flow limiter, it’s important for you to consider the following factors:

- System requirements: Ensure that the restrictor meets the specific requirements of the system it will use, including flow rate, pressure, and compatibility with the gas type.

- Design: Ensure that the restrictor design is appropriate for the system and will function as intended. It may include choosing the right type of restrictor, such as a fixed orifice or adjustable restrictor, and selecting the right materials for the application.

- Manufacturing: Ensure that the restrictor is manufactured to the highest standards, using high-quality materials and precision machining.

- Testing: Test the restrictor thoroughly before installation to ensure that it meets all performance requirements and functions as intended.

- Installation: Proper restrictor installation is critical to its performance and safety. Ensure it is installed according to the manufacturer’s instructions and local codes and regulations.

By paying attention to these factors and following best practices for customizing a gas flow restrictor, you can help ensure that your restrictor meets your system requirements, performs as intended, and operates safely.

High Quality HPLC Column 316L, 316 Stainless Steel Tube Materials

Design New Gas Flow Restrictor 100% As Clients Request

Make Gss Flow Restrictor Elements And Test Before Mass Products.

What Clients Say

The gas flow restrictor from uHPLC has made a huge difference in the performance of our high-pressure liquid chromatography system. It has increased the accuracy and precision of our results and has made our work much more efficient.

Amanda LeeCEO

I was skeptical about the gas flow restrictor at first, but after trying it, I was pleasantly surprised. It has completely transformed our high-pressure liquid chromatography system, and we are getting much better results now.

Adam CheiseDesigner

We have been using the gas flow restrictor from uHPLC for several months now, and we have been thoroughly impressed with its performance. It has made our liquid chromatography work much easier and more precise.

Floyd StallerCo-Founder

The gas flow restrictor is a must-have accessory for any high-pressure liquid chromatography system. It has increased our productivity and has made our work much more reliable.

Floyd StallerCo-Founder

We highly recommend the gas flow restrictor from uHPLC to anyone looking to improve the performance of their liquid chromatography system. It is easy to install and has made a huge difference in the quality of our results.

Floyd StallerCo-Founder

Previous

Next

Contact Us & Custom Your Gas Flow Restrictor

Take control of your gas flow and ensure optimal performance with a customized solution. Our knowledgeable sales team is ready to assist you in finding the perfect restrictor for your needs. Don’t miss this opportunity to improve your gas flow efficiency – contact us today to get started!

HPLC Column FAQ

What is Porous Metal Gas Flow Restrictor ?

A porous metal gas flow restrictor is a versatile device used to precisely control the flow rate of gases in various applications. It offers a reliable and cost-effective alternative to traditional small control valves.

- Material Versatility: Porous metal restrictors are typically available in various corrosion-resistant materials like stainless steel, Inconel, Monel, Hastelloy, and even precious metals like gold and silver. This allows them to withstand harsh environments and be compatible with different gases.

Applications of Gas Flow Restrictor

Gas flow restrictors are used in various applications to control and regulate the flow of gases. Some common applications include:

- Medical Equipment: In medical devices such as ventilators, gas flow restrictors are used to control the flow of air or oxygen to patients.

- Industrial Processes: Restrictors control the flow of gases, such as natural gas, propane, and others, to ensure safe and efficient operations.

- Fuel Systems: In fuel systems, such as vehicles or aircraft, restrictors regulate fuel flow to the engine, ensuring optimal performance.

- Environmental Control: In HVAC and refrigeration systems, restrictors control the flow of gases, such as refrigerants, and regulate the pressure in these systems.

- Instrumentation: In laboratory and scientific instrumentation, restrictors control the flow of gases for accurate measurements and analysis.

Gas flow restrictors ensure safe and efficient operations in various industries and applications.

Working Principle of Gas Flow Limiter in HPLC System ?

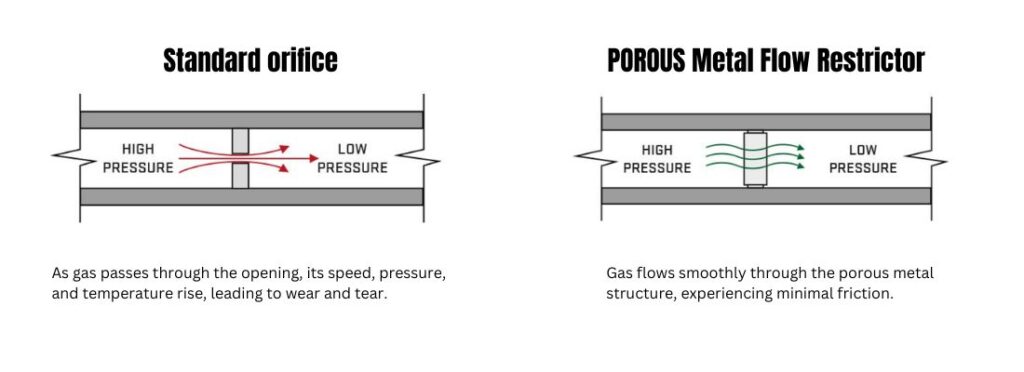

A porous metal gas flow limiter operates on a similar principle to other gas flow limiters in HPLC systems, but with a unique mechanism:

1. Porous Structure:

- Unlike conventional limiters with fixed orifices or valves, porous metal limiters consist of a sintered metal matrix with thousands of microscopic pores. These pores act as multiple flow paths for the gas.

2. Flow Restriction:

- As the gas flows through the tortuous network of pores, its velocity increases due to the reduced cross-sectional area compared to a single orifice. This increase in velocity creates a pressure drop across the limiter, restricting the overall flow rate.

3. Pressure-Independent Flow:

- The large number of flow paths in a porous metal limiter makes it less susceptible to pressure fluctuations compared to single-orifice designs. This is because the pressure drop is distributed across numerous channels, minimizing the impact of upstream pressure variations on the overall flow rate.

4. Additional Benefits:

- Laminar Flow: The intricate pore structure promotes laminar flow, reducing turbulence and improving the consistency of gas delivery to the nebulizer.

- Clogging Resistance: The numerous flow paths make the limiter less prone to clogging by small particles present in the gas stream.

- Durability: Porous metal is known for its high strength and resistance to corrosion, ensuring reliable performance over extended periods.

5. Selection and Considerations:

Similar to other limiters, choosing the appropriate porous metal option requires considering:

- Nebulizer compatibility: Ensure the inner diameter of the limiter matches the nebulizer outlet.

- Flow rate requirements: Select a limiter with a suitable pore size and material to achieve the desired flow rate.

- Pressure rating: Choose a limiter that can withstand the operating pressure of your HPLC system.

Overall, porous metal gas flow limiters offer a reliable and efficient way to regulate gas flow in HPLC systems. Their unique structure provides consistent flow control, minimizes pressure dependence, and offers additional benefits like laminar flow and clog resistance.

Frequently Asked Questions

A flow restrictor valve is a device designed to limit or control the flow of a fluid (like gas or liquid) through a system or component. It’s used in various applications where it’s necessary to maintain a specific flow rate or to reduce the flow to a desired level.

Here’s a breakdown of its features and functions:

Controlled Flow: The primary purpose of a flow restrictor valve is to control the flow rate of a fluid. This can be to ensure that a system operates efficiently, to prevent overloading of a component, or to ensure that a process receives the right amount of fluid.

Design: Flow restrictor valves can come in various designs. Some are simple orifices or nozzles with a fixed diameter, while others are adjustable, allowing for manual or automatic changes to the flow rate.

Adjustability: Some flow restrictor valves are adjustable, meaning the user can set the desired flow rate. This is often done by turning a knob or using an electronic control system.

Feedback Mechanism: Advanced flow restrictor valves might have feedback systems that automatically adjust the flow rate based on sensors or other input. For example, in a cooling system, if a temperature sensor detects that a component is getting too hot, the flow restrictor valve might automatically increase the flow of coolant.

Applications: Flow restrictor valves are used in a wide range of applications, from household plumbing systems (like in showerheads to conserve water) to industrial processes. They’re also common in hydraulic and pneumatic systems to control the flow of fluids.

Safety: In some systems, flow restrictor valves can act as a safety feature. By limiting the flow rate, they can prevent over-pressurization or excessive wear on components.

In essence, a flow restrictor valve is a crucial component in many systems, ensuring that they operate efficiently, safely, and effectively by controlling the flow of fluids.

As We Know A flow restrictor valve is a device designed to control or limit the flow rate of a fluid (either gas or liquid) within a system. Its primary function is to ensure a specific flow rate or to reduce the flow to a desired level.

Key points about a flow restrictor valve:

Purpose: Its main purpose is to regulate the flow of a fluid, ensuring that a system or component receives fluid at the correct rate.

Design: They can be simple fixed orifices or more complex adjustable valves. The design chosen often depends on the application and the level of control required.

Adjustability: Some flow restrictor valves allow for manual adjustment, enabling users to set a specific flow rate. This can be done by turning a knob or using a lever.

Applications: They are used in various settings, from household fixtures like faucets and showerheads (to conserve water) to industrial machinery and hydraulic systems where precise flow control is crucial.

Operation: The valve operates by creating a resistance to the flow, which results in a pressure drop across the valve. This resistance can be adjusted in some valves to change the flow rate.

Safety: Flow restrictor valves can also serve as safety devices in some systems. By controlling the flow rate, they can prevent issues like over-pressurization or potential damage to equipment.

In summary, a flow restrictor valve is a tool used in many fluid systems to ensure controlled and consistent fluid flow, enhancing system efficiency and safety.

A flow restrictor valve creates resistance to fluid or gas flow through a restriction or narrowing in the valve, which decreases the maximum flow rate.

Flow restrictor valves come in various designs and types, each suited for specific applications or requirements. Here are some common types of flow restrictor valves:

Fixed Orifice Restrictors: These are the simplest form of flow restrictors. They consist of a plate or fitting with a hole (orifice) of a specific diameter. The size of the orifice determines the flow rate. They are non-adjustable and provide a constant flow rate based on the differential pressure across the orifice.

Adjustable Flow Restrictors: These allow users to manually adjust the flow rate. They typically have a knob or screw mechanism that changes the size of the orifice or the degree of constriction, thereby adjusting the flow rate.

Needle Valves: These are a type of adjustable flow restrictor. They use a tapered pin (needle) that can be screwed in or out to vary the opening size, thus controlling the flow rate.

Ball Valves: While primarily used as on/off valves, when partially opened, ball valves can act as flow restrictors. The degree of opening determines the flow rate.

Throttle Valves: These are designed to control flow rate by varying the cross-sectional area available for flow. They can be manually or automatically adjusted.

Check Valves with Flow Restriction: Some check valves (which allow flow in one direction only) have built-in flow restrictors to control the flow rate in the allowed direction.

Diaphragm Valves: These use a flexible diaphragm that can be adjusted to vary the flow rate. The position of the diaphragm determines the flow restriction.

Rotary Valves: These use a rotating mechanism to control the flow rate. The position of the rotary element determines the degree of flow restriction.

Pressure-compensated Flow Restrictors: These are designed to maintain a constant flow rate regardless of changes in system pressure. They often use a combination of orifices and compensating mechanisms, such as springs or diaphragms, to adjust the flow automatically based on the pressure.

Differential Pressure Flow Restrictors: These maintain a constant differential pressure across themselves, which can result in a relatively constant flow rate, especially if the fluid properties and temperature remain stable.

Each type of flow restrictor valve has its advantages, limitations, and ideal applications. The choice of a specific type depends on factors like the required precision of flow control, system pressure, fluid type, and desired adjustability.

Flow restrictor valves are commonly used in industrial, residential, and commercial plumbing, HVAC systems, and the medical industry to control the flow of gases and liquids.

Yes, flow restrictor valves can be adjusted by changing the size of the restriction or by adjusting the valve’s settings to alter the flow rate.

The desired flow rate and the pressure drop across the valve determine the size of a flow restrictor valve.

Yes, flow restrictor valves can be cleaned by removing any debris that may have accumulated in the valve’s restriction.

Yes, flow restrictor valves can fail due to wear and tear corrosion or damage from debris or foreign objects.

Replacing a gas flow restrictor requires careful attention to safety, given the potential hazards associated with gas leaks. Here’s a general guideline for replacing a gas flow restrictor:

Safety First: Always ensure that the gas supply is turned off and that the area is well-ventilated. If you smell gas at any point, stop what you’re doing, evacuate the area, and call a professional or emergency services.

Preparation:

- Gather necessary tools: wrenches, screwdrivers, replacement restrictor, Teflon tape or thread sealant, etc.

- Turn off the gas supply at the main valve or the specific appliance’s shut-off valve.

- Ensure the area is well-ventilated.

Locate the Gas Flow Restrictor:

- The flow restrictor is typically located near the gas inlet of an appliance or within the gas line system.

- Refer to the appliance’s manual or schematic diagrams if available.

Removal:

- Use the appropriate wrench to disconnect the gas line or fitting where the flow restrictor is located. Be gentle to avoid damaging any connections.

- Once disconnected, you should be able to access and remove the flow restrictor. It might be a small disc or a fitting with a specific orifice size.

Install the New Gas Flow Restrictor:

- Place the new flow restrictor in the same position as the old one. Ensure it’s oriented correctly.

- If threads are involved, apply Teflon tape or thread sealant to ensure a gas-tight connection.

Reconnect:

- Carefully reconnect the gas line or fitting. Ensure all connections are tight and secure.

Test:

- Slowly turn the gas supply back on.

- Check for any signs of gas leaks using a gas leak detector or a soapy water solution (bubbles will form if there’s a leak). If you detect a leak, turn off the gas supply immediately and tighten connections or seek professional help.

- Once you’re sure there are no leaks, test the appliance or system to ensure the gas flow is appropriate.

Dispose of the Old Restrictor:

- Ensure you dispose of the old restrictor in an environmentally friendly manner.

Note: If you’re unsure or uncomfortable with any step, it’s always best to hire a professional or expert to handle the replacement. Gas systems can be dangerous if not handled correctly, and safety should always be the top priority.

Need Help ?

Contact uHPLCs Today for Any Questions for HPLC / UHPLC

+(86) 0755-28502380

sales@uhplcs.com

Contact Us

Recent Posts

Types of HPLC Solvent Filters and How to Choose

Introduction In High Performance Liquid Chromatography (HPLC), the purity of solvents is paramount for achieving

HPLC Prep HPLC Columns Full Guide

High-performance liquid chromatography (HPLC) is a workhorse technique in labs worldwide, separating complex mixtures into