How to Prevent and Solve Resolution Loss in HPLC Workflows

Introduction In High-Performance Liquid Chromatography (HPLC), resolution is a key factor that determines the ability

Home » Gas Flow Restrictor

uHPLCs is a leading OEM supplier of porous metal gas flow restrictor elements. Our products are designed to provide precise control over gas flow, making them ideal for various applications, including high-performance liquid chromatography (HPLC), ultra-high-performance liquid chromatography (uHPLC), and mass spectrometry. Our products are made from high-quality materials, ensuring they are durable, reliable, and long-lasting.

One of the key benefits of our metal porous gas flow restrictor elements is their precise control over the gas flow. It is achieved through advanced materials and manufacturing techniques, which allow for the creation of precise micro-scale orifices that can be adjusted with great accuracy. This results in a level of control over gas flow that is unparalleled by other suppliers in the industry.

In addition to our precise control over gas flow, uHPLCs’ products are also designed to be highly efficient. It is achieved through low-resistance orifices, allowing high-speed, high-resolution analysis. The company’s products are also designed to be low maintenance, with long-lasting performance that reduces the need for frequent replacements.

Model:

AR-31-58-6500-005

Size:

Ф3.17*H3.17mm

Model:

AR-AR-09-60-6700-005

Size:

Ф9.9*H6.05mm

M10*1mm Thread

Model:

AR-49-60-0220-100

Size:

ф4.9*H5.85

M5*0.8 Thread

Model:

AR-41-58-5500-005

Size:

Ф3.17*H4.17mm

Model:

AR-63-60-1100-600

Size:

ф6.35*H6.35mm

Model:

AR-08-60-1000-800

Size:

ф8*H27mm

UNF10-32"Thread

Model:

AR-08-60-0400-300

Size:

Ф8*H27mm

UNF10-32"Thread

Model:

AR-15-10-5920-174

Size:

Ф15*H30 ID Ф6

M8.5*1.0 Thread

Model:

AR-08-60-4500-005

Size:

ф8*H22.5

To ensure that our Metal Porous Gas Flow Restrictor meet your higher quality standards, uHPLCs employs a team of highly skilled engineers and technicians. These individuals work closely with customers to understand their specific needs and requirements and design and manufacture products that meet them.

Porous stainless steel gas flow restrictors are versatile components that provide precise flow control, pressure regulation, and safety in various industrial and laboratory applications. Their durability, resistance to corrosion, and ability to handle extreme conditions make them highly valuable. Below are applications of porous stainless steel gas flow restrictors and their key benefits:

| Application Area | Specific Applications | Key Benefits |

|---|---|---|

| Analytical Instruments | – Gas Chromatography (GC) systems – Mass Spectrometers | – Precise gas flow control – Stable and consistent delivery |

| Medical Devices | – Oxygen concentrators – Anesthesia delivery systems | – Ensures patient safety – Prevents pressure surges |

| Industrial Gas Systems | – Welding gas regulation – Inert gas blanketing – Natural gas distribution | – Avoids overpressure – Provides stable flow in high-demand environments |

| Catalytic and Reaction Systems | – Gas flow in chemical reactors – Catalytic bed distribution | – Uniform gas distribution – Optimizes reaction conditions |

| Flammable Gas Safety | – Hydrogen pipelines – Gas supply in explosive environments | – Limits excessive flow during leaks – Withstands harsh conditions |

| Microelectronics | – High-purity gas flow for wafer fabrication – Vacuum chambers | – Contamination-free gas delivery – Precise control in tight tolerances |

| Aerospace and Defense | – Rocket propulsion systems – Spacecraft life support | – Reliable under extreme conditions – Durable in critical systems |

| Environmental Monitoring | – Air quality monitoring – Emission testing systems | – Accurate sampling – Corrosion resistance |

| Energy Systems | – Hydrogen fuel cells – Biogas flow regulation | – Stable gas flow – Withstands variable gas compositions |

| Customizable Solutions | – Tailored flow restrictors for research and industry | – Meets specific flow and pressure needs – Long service life |

Overall, uHPLCs is a leading OEM supplier of gas flow restrictor elements, providing precise control over gas flow, high efficiency, and low maintenance. Their products are designed to meet the needs of a wide range of applications, including HPLC, uHPLC, and mass spectrometry. They are made from high-quality materials to ensure they are reliable, durable, and long-lasting. If you need a high-quality gas flow restrictor element for your application, look no further than uHPLCs.

Unlock Maximum Efficiency with Our Gas Flow Restrictor! This innovative device accurately regulates the gas flow, ensuring optimal performance and minimizing waste. Don’t settle for less – upgrade to the best gas flow solution today!

Ultra-high-performance liquid chromatography (uHPLC) systems incorporating a gas flow restrictor have become increasingly popular in the field of chromatography due to their many benefits. Here are some key reasons why working with uHPLCs for gas flow restrictors is advantageous:

In conclusion, uHPLCs that utilizes a gas flow restrictor provide many advantages over traditional HPLC systems, including improved resolution, increased efficiency, reduced analysis time, increased sensitivity, better control of pressure and flow rate, and reduced solvent consumption.

When customizing a gas flow restrictor or gas flow limiter, it’s important for you to consider the following factors:

By paying attention to these factors and following best practices for customizing a gas flow restrictor, you can help ensure that your restrictor meets your system requirements, performs as intended, and operates safely.

High Quality HPLC Column 316L, 316 Stainless Steel Tube Materials

Design New Gas Flow Restrictor 100% As Clients Request

Make Gss Flow Restrictor Elements And Test Before Mass Products.

Take control of your gas flow and ensure optimal performance with a customized solution. Our knowledgeable sales team is ready to assist you in finding the perfect restrictor for your needs. Don’t miss this opportunity to improve your gas flow efficiency – contact us today to get started!

A porous metal gas flow restrictor is a versatile device used to precisely control the flow rate of gases in various applications. It offers a reliable and cost-effective alternative to traditional small control valves.

Gas flow restrictors are used in various applications to control and regulate the flow of gases. Some common applications include:

Gas flow restrictors ensure safe and efficient operations in various industries and applications.

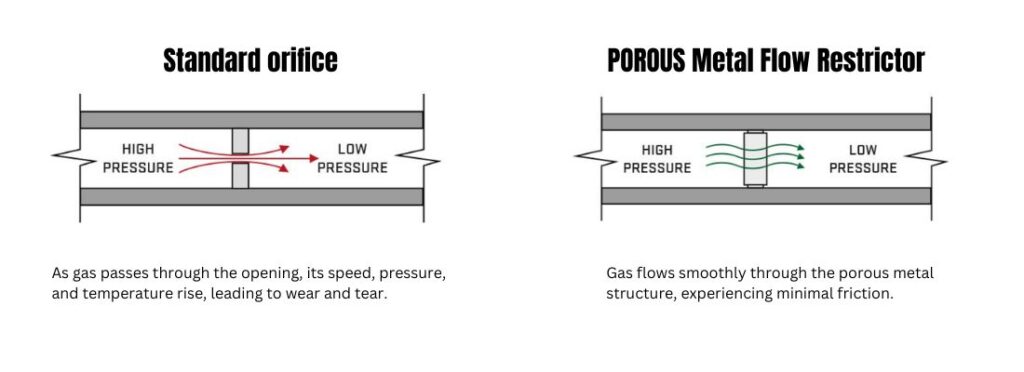

A porous metal gas flow limiter operates on a similar principle to other gas flow limiters in HPLC systems, but with a unique mechanism:

1. Porous Structure:

2. Flow Restriction:

3. Pressure-Independent Flow:

4. Additional Benefits:

5. Selection and Considerations:

Similar to other limiters, choosing the appropriate porous metal option requires considering:

Overall, porous metal gas flow limiters offer a reliable and efficient way to regulate gas flow in HPLC systems. Their unique structure provides consistent flow control, minimizes pressure dependence, and offers additional benefits like laminar flow and clog resistance.

A flow restrictor valve is a device designed to limit or control the flow of a fluid (like gas or liquid) through a system or component. It’s used in various applications where it’s necessary to maintain a specific flow rate or to reduce the flow to a desired level.

Here’s a breakdown of its features and functions:

Controlled Flow: The primary purpose of a flow restrictor valve is to control the flow rate of a fluid. This can be to ensure that a system operates efficiently, to prevent overloading of a component, or to ensure that a process receives the right amount of fluid.

Design: Flow restrictor valves can come in various designs. Some are simple orifices or nozzles with a fixed diameter, while others are adjustable, allowing for manual or automatic changes to the flow rate.

Adjustability: Some flow restrictor valves are adjustable, meaning the user can set the desired flow rate. This is often done by turning a knob or using an electronic control system.

Feedback Mechanism: Advanced flow restrictor valves might have feedback systems that automatically adjust the flow rate based on sensors or other input. For example, in a cooling system, if a temperature sensor detects that a component is getting too hot, the flow restrictor valve might automatically increase the flow of coolant.

Applications: Flow restrictor valves are used in a wide range of applications, from household plumbing systems (like in showerheads to conserve water) to industrial processes. They’re also common in hydraulic and pneumatic systems to control the flow of fluids.

Safety: In some systems, flow restrictor valves can act as a safety feature. By limiting the flow rate, they can prevent over-pressurization or excessive wear on components.

In essence, a flow restrictor valve is a crucial component in many systems, ensuring that they operate efficiently, safely, and effectively by controlling the flow of fluids.

As We Know A flow restrictor valve is a device designed to control or limit the flow rate of a fluid (either gas or liquid) within a system. Its primary function is to ensure a specific flow rate or to reduce the flow to a desired level.

Key points about a flow restrictor valve:

Purpose: Its main purpose is to regulate the flow of a fluid, ensuring that a system or component receives fluid at the correct rate.

Design: They can be simple fixed orifices or more complex adjustable valves. The design chosen often depends on the application and the level of control required.

Adjustability: Some flow restrictor valves allow for manual adjustment, enabling users to set a specific flow rate. This can be done by turning a knob or using a lever.

Applications: They are used in various settings, from household fixtures like faucets and showerheads (to conserve water) to industrial machinery and hydraulic systems where precise flow control is crucial.

Operation: The valve operates by creating a resistance to the flow, which results in a pressure drop across the valve. This resistance can be adjusted in some valves to change the flow rate.

Safety: Flow restrictor valves can also serve as safety devices in some systems. By controlling the flow rate, they can prevent issues like over-pressurization or potential damage to equipment.

In summary, a flow restrictor valve is a tool used in many fluid systems to ensure controlled and consistent fluid flow, enhancing system efficiency and safety.

A flow restrictor valve creates resistance to fluid or gas flow through a restriction or narrowing in the valve, which decreases the maximum flow rate.

Flow restrictor valves come in various designs and types, each suited for specific applications or requirements. Here are some common types of flow restrictor valves:

Fixed Orifice Restrictors: These are the simplest form of flow restrictors. They consist of a plate or fitting with a hole (orifice) of a specific diameter. The size of the orifice determines the flow rate. They are non-adjustable and provide a constant flow rate based on the differential pressure across the orifice.

Adjustable Flow Restrictors: These allow users to manually adjust the flow rate. They typically have a knob or screw mechanism that changes the size of the orifice or the degree of constriction, thereby adjusting the flow rate.

Needle Valves: These are a type of adjustable flow restrictor. They use a tapered pin (needle) that can be screwed in or out to vary the opening size, thus controlling the flow rate.

Ball Valves: While primarily used as on/off valves, when partially opened, ball valves can act as flow restrictors. The degree of opening determines the flow rate.

Throttle Valves: These are designed to control flow rate by varying the cross-sectional area available for flow. They can be manually or automatically adjusted.

Check Valves with Flow Restriction: Some check valves (which allow flow in one direction only) have built-in flow restrictors to control the flow rate in the allowed direction.

Diaphragm Valves: These use a flexible diaphragm that can be adjusted to vary the flow rate. The position of the diaphragm determines the flow restriction.

Rotary Valves: These use a rotating mechanism to control the flow rate. The position of the rotary element determines the degree of flow restriction.

Pressure-compensated Flow Restrictors: These are designed to maintain a constant flow rate regardless of changes in system pressure. They often use a combination of orifices and compensating mechanisms, such as springs or diaphragms, to adjust the flow automatically based on the pressure.

Differential Pressure Flow Restrictors: These maintain a constant differential pressure across themselves, which can result in a relatively constant flow rate, especially if the fluid properties and temperature remain stable.

Each type of flow restrictor valve has its advantages, limitations, and ideal applications. The choice of a specific type depends on factors like the required precision of flow control, system pressure, fluid type, and desired adjustability.

Flow restrictor valves are commonly used in industrial, residential, and commercial plumbing, HVAC systems, and the medical industry to control the flow of gases and liquids.

Yes, flow restrictor valves can be adjusted by changing the size of the restriction or by adjusting the valve’s settings to alter the flow rate.

The desired flow rate and the pressure drop across the valve determine the size of a flow restrictor valve.

Yes, flow restrictor valves can be cleaned by removing any debris that may have accumulated in the valve’s restriction.

Yes, flow restrictor valves can fail due to wear and tear corrosion or damage from debris or foreign objects.

Replacing a gas flow restrictor requires careful attention to safety, given the potential hazards associated with gas leaks. Here’s a general guideline for replacing a gas flow restrictor:

Safety First: Always ensure that the gas supply is turned off and that the area is well-ventilated. If you smell gas at any point, stop what you’re doing, evacuate the area, and call a professional or emergency services.

Preparation:

Locate the Gas Flow Restrictor:

Removal:

Install the New Gas Flow Restrictor:

Reconnect:

Test:

Dispose of the Old Restrictor:

Note: If you’re unsure or uncomfortable with any step, it’s always best to hire a professional or expert to handle the replacement. Gas systems can be dangerous if not handled correctly, and safety should always be the top priority.

Contact uHPLCs Today for Any Questions for HPLC / UHPLC

Introduction In High-Performance Liquid Chromatography (HPLC), resolution is a key factor that determines the ability

Introduction Have you ever started an HPLC run only to see the system pressure shoot

1. Introduction to HPLC Column Size High-Performance Liquid Chromatography (HPLC) is a cornerstone of modern

WhatsApp us

Subscribe for exclusive offers and updates on new arrivals