What is Void Volume and Its Impact

Dead volume refers to the unmoving, stagnant, or unswept space in a chromatography system, which is a part of the internal volume.

The International Union of Pure and Applied Chemistry (IUPAC) defines dead volume as the mobile-phase volume that solutes experience outside of the column.

Void volume, another component of internal volume, is calculated to prevent issues like sample diffusion and peak broadening.

Dead volume can affect chromatography separations, causing peak separation and quantification issues for the sample. Excess dead volumes can broaden peaks and compromise resolution, making it challenging for chromatographers to achieve accurate results.

Dead time, the retention time of unretained components within the system, impacts chromatographic resolution and peak separation. Calculating and minimizing dead time is crucial for optimal chromatography performance.

Dead volume can be calculated by measuring the holdup volume and subtracting it from the geometric column mobile-phase volume.

The extracolumn (dead) volume may be calculated by measuring the holdup volume and subtracting it from the geometric column mobile-phase volume.

What is the difference between dead volume and dwell volume?

In chromatography, “dead volume” and “dwell volume” are terms that refer to different aspects of the flow path in the system. Here’s how they differ:

Dead volumes can affect chromatographic results by causing peak broadening and compromising resolution.

1. Dead Volume (Void Volume)

Definition: Dead volume, often called “void volume,” is the volume in the chromatographic system where the mobile phase flows but there is no interaction with the stationary phase. It is primarily within the column, including the space between the packed particles and the internal tubing or connections where separation doesn’t occur.

Measurement: Dead volume is typically determined by injecting an unretained compound (one that does not interact with the stationary phase) and measuring the time or volume required for it to reach the detector.

Impact on Chromatography: The dead volume affects the retention times of all components and plays a crucial role in determining peak shape. Excessive dead volumes can lead to band broadening and affect the efficiency of the separation, as stagnant spaces cause peaks to broaden and compromise resolution.

Components Included: Includes internal column volume and any volume where there is no selective retention of analytes, often related to the flow path within the column itself.

2. Dwell Volume

Definition: Dwell volume (also called “gradient delay volume”) refers to the volume of mobile phase that exists between the point where solvents are mixed (such as a mixing chamber or gradient mixer) and the inlet of the chromatographic column. It essentially represents the time delay before a change in mobile phase composition reaches the column in a gradient method.

Measurement: Dwell volume is important when using gradient elution, as it impacts how quickly the gradient reaches the column after a change is made. It can be measured by substituting a component of the mobile phase with a UV-absorbing solvent and monitoring the change at the detector.

Impact on Chromatography: Dwell volume directly affects gradient methods. Different dwell volumes in HPLC systems can lead to different delays in when a gradient actually reaches the column, causing variability in retention times if the method is transferred between systems with differing dwell volumes.

Components Included: Dwell volume comprises the volume of tubing, mixer, pump heads, and any other component between the solvent mixer and the column inlet.

Summary

Dead Volume: Refers to the volume where no separation occurs, primarily in the column or connection tubing, and it affects overall peak width and chromatographic efficiency. Controlling dead volumes is crucial for optimizing chromatographic methods and reducing peak broadening.

Dwell Volume: Refers to the volume between the mixing point and the column, affecting the delay of a gradient to reach the column in gradient methods, thus impacting the reproducibility of retention times in gradient elution.

Understanding both volumes is essential to optimizing chromatographic methods, especially when trying to reduce peak broadening, ensure consistent retention times, and troubleshoot system-related issues in both isocratic and gradient methods.

Minimizing Dead Volume: Causes, Effects, and Solutions

Causes of Dead Volume

Unswept dead volume can influence injection, causing solute and solvent to enter the area near the inlet septum by diffusion or under the influence of the internal pressure pulse caused by solvent vaporization.

In gas chromatography, the carrier gas plays a crucial role in the separation process. It impacts the flow dynamics and can significantly influence dead volumes, affecting peak resolution and analytical results. Excess dead volume can broaden peaks and compromise resolution, making it essential to control this phenomenon in chromatography systems.

Septum purge flow helps to sweep away solute and solvent from the main carrier flow and prevent tailing solute profiles.

The dead volume consists of four parts: injector to column pipeline, particle gap of stationary phase, column outlet pipeline, and detector flow pool.

Understanding swept volume, along with dead volume, is essential as both can affect the chromatography process by influencing peak shape and width. A larger dead volume can cause peak broadening.

Effects of Dead Volume

Dead volumes can cause serious trouble for chromatographers, making peaks tail and broaden, and compromising peak resolution. A figure illustrating the effects of dead volume on peak profiles, such as peak broadening and tailing, can help visualize these issues.

The dead volume can cause chromatographic effects, such as peak broadening and reduced resolution, in capillary connections.

The dwell volume is responsible for the time delay in a gradient HPLC system.

By definition, it is the volume between the mixing chamber and the column inlet.

Where does dead volume exist in a liquid chromatography system?

In a liquid chromatography system, dead volume (also referred to as void volume) refers to any part of the system that contributes volume without contributing to the separation of analytes. Dead volume exists in several areas along the chromatographic path where the mobile phase flows, but analytes are not interacting with the stationary phase, and thus, separation is not occurring. Dead volumes can affect peak separation and quantification, particularly in gas chromatography. Here are the common places in a liquid chromatography system where dead volume can exist:

1. Tubing and Connections

Pre-column Tubing: Tubing that connects the injector to the column can contribute to dead volume. The inner diameter and length of this tubing are critical factors—larger or longer tubing can significantly increase dead volumes, leading to broader peaks and compromised resolution in chromatographic results.

Post-column Tubing: Tubing connecting the column outlet to the detector can also contribute to dead volume. It is important to minimize the length and diameter of this tubing to reduce dead volumes, as excessive dead volume can cause band broadening after separation.

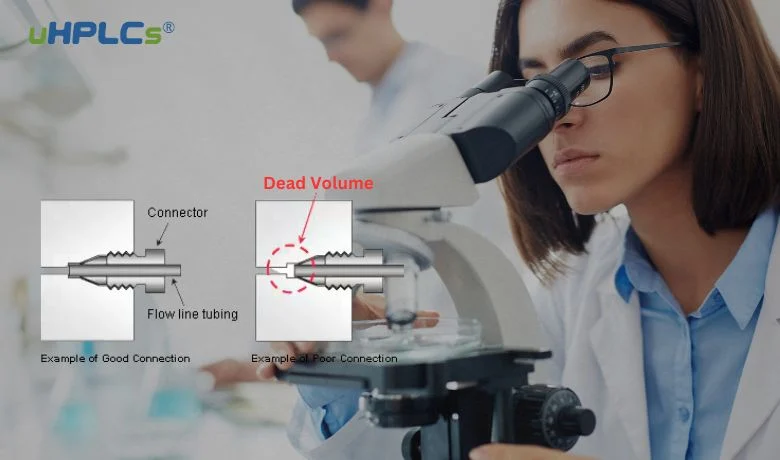

2. Fittings and Connectors

Fittings and Unions: Poorly designed fittings, loose connections, or mismatched ferrules can introduce unnecessary dead volumes. These stagnant spaces can cause mixing and result in peak broadening, affecting chromatographic results. Ensuring that fittings are properly connected and minimizing unnecessary unions are important steps in reducing dead volume.

3. Injector System

Injection Valve: The sample injector or valve can have internal pathways where the mobile phase flows without contributing to the separation. If these internal volumes are too large, they add dead volumes to the system, which can affect peak separation and quantification. Excess dead volume can broaden peaks and compromise resolution, posing significant challenges to chromatographers, especially in gas chromatography.

4. Column End Fittings

Column Inlet and Outlet: Dead volumes may also exist at the column inlet and outlet if the end fittings are not properly designed or if there are gaps between the column packing and the frit. These stagnant spaces can result in reduced efficiency by broadening peaks and compromising resolution. A poorly packed column or a damaged frit can increase the volume at the column ends, exacerbating this issue.

5. Guard Column

Guard Column Connections: If a guard column is used to protect the main column, improper connection between the guard column and the analytical column can introduce dead volumes. Any gap or improper fitting can result in mixing and increased dead volume, which can affect peak separation and quantification, particularly in gas chromatography.

6. Detector Flow Cell

Detector Volume: The detector flow cell also contributes to dead volumes, which can cause separated peaks to merge, resulting in poor resolution. The cell volume should be minimized to prevent peak broadening. Flow cells with large internal volumes can cause separated peaks to merge, resulting in poor resolution.

Importance of Minimizing Dead Volume

Dead volumes can have a significant impact on peak shape and chromatographic efficiency, leading to peak broadening and poor efficiency. Excessive dead volume leads to:

Peak Broadening: Reduces resolution between analytes, making it difficult to distinguish closely eluting compounds.

Poor Efficiency: Contributes to lower theoretical plate counts, affecting overall separation quality.

Additionally, free space plays a crucial role in determining the efficiency and accuracy of measurements involved in gas density and peak shape during chromatography.

To minimize dead volume, it is crucial to use narrow and properly connected tubing, minimize the number of fittings and connectors, ensure proper packing in columns, and choose a detector with a small flow cell volume. Every component in the liquid chromatography system should be optimized to minimize areas where analytes can mix rather than separate.

Strategies for Minimizing Dead Volume

What we can do ?

so after knowing where the dead volume exist , so what we can do and strategies for Minimizing Dead Volume for each part of liquid chromatography system ?

Minimizing dead volume in a liquid chromatography system is essential to ensure sharp peak shapes, maintain high separation efficiency, and achieve better resolution between closely eluting analytes. Here are strategies for minimizing dead volume for each key part of the system:

1. Tubing and Connections

Use Narrow Diameter Tubing: Select tubing with the narrowest internal diameter that is appropriate for the flow rate you are using. Typically, 1/16″ outer diameter tubing with a 0.005″-0.010″ inner diameter is used for HPLC.

Shorten Tubing Lengths: Minimize the length of tubing between system components (e.g., from the injector to the column and from the column to the detector). The longer the tubing, the greater the dead volume, which can lead to peak broadening.

Avoid Unnecessary Tubing: Eliminate any unnecessary loops or excess tubing. Extra loops introduce additional volume where mixing can occur, contributing to dead volume.

2. Fittings and Connectors

Use Zero-Dead-Volume (ZDV) Fittings: Employ zero-dead-volume fittings to ensure there is no gap between the tubing and connectors. Dead volumes can cause mixing and result in peak broadening, affecting chromatographic results. ZDV fittings ensure a tight and smooth connection without any extra volume that could cause mixing.

Properly Tighten Fittings: Over-tightening or under-tightening can cause poor connections and introduce gaps that add dead volume. Follow manufacturer recommendations for tightening to ensure optimal connection.

Use Compatible Components: Ensure that ferrules and fittings are matched to the type and diameter of the tubing to avoid creating spaces that can cause dead volume. Improper matching of parts can result in poorly sealed connections.

3. Injector System

Minimize Injection Loop Volume: Use the smallest injection loop that suits your sample size. Larger loops add unnecessary volume, especially if you are injecting small sample volumes, leading to extra dead volume.

Check for Flow Path Restrictions: Ensure that the internal pathways of the injector are clean and free from obstructions. Obstructions can cause unpredictable flow patterns and create additional dead volume.

4. Column End Fittings

Ensure Proper Column Packing: Make sure that the column is well-packed, with no gaps at the column inlet or outlet. Poorly packed columns can lead to dead volumes in the headspace of the column, resulting in reduced efficiency by broadening peaks and compromising resolution.

Use Quality Frits and End Fittings: Choose columns with well-designed end fittings and frits that match the packing material well. Any space between the frit and the packing material can cause mixing and lead to peak broadening.

5. Guard Column

Proper Connection to Main Column: Make sure that the guard column is tightly connected to the analytical column, with no gaps between them. Dead volumes can result in mixing and increased dead volume, which can affect peak separation and quantification. You can use direct connect hardware to ensure a seamless connection, reducing dead volume between the guard column and the main column.

Use Short Guard Columns: Use a guard column with the shortest possible length that effectively protects the main column. Excess guard column length can increase dead volume and add to the overall system volume.

6. Detector Flow Cell

Use a Small-Volume Flow Cell: Choose a detector flow cell with a low internal volume that suits the scale of the separation. Dead volumes, which are stagnant spaces within the system, can cause separated peaks to merge, resulting in poor resolution. For analytical-scale HPLC, a small-volume flow cell (e.g., 5-10 µL) is preferable to prevent peak broadening.

Avoid Extra Connectors to the Detector: Minimize tubing and connections between the column outlet and the detector. Any additional volume before the detector can contribute to band broadening.

Additional General Strategies

Reduce Dead Space in Mobile Phase Mixer: If working with a gradient system, use a low-volume mixer to ensure the gradient reaches the column quickly and consistently, reducing dwell volume and minimizing any impact on retention times. Minimizing dead volumes is essential for achieving better resolution between closely eluting analytes.

Regular Maintenance and Inspections: Regularly check and replace worn-out tubing, fittings, and connectors. Old parts can degrade over time, causing leaks, gaps, or other issues that may contribute to dead volume.

Minimize Connections Between Components: Every connection point introduces the potential for dead volume. Simplify the system by minimizing the number of fittings, unions, or adaptors used.

System Suitability Testing: Regularly perform system suitability tests using standards that can assess the efficiency of the chromatographic system. Broad peaks or inconsistent retention times may indicate the presence of excessive dead volume.

Summary

By optimizing each component of the liquid chromatography system and focusing on reducing or eliminating unnecessary spaces where mixing can occur, you can effectively minimize dead volume. The key is to ensure seamless, narrow-diameter, and direct flow paths between each part of the system to maintain sharp, well-resolved chromatographic peaks. Controlling dead volumes is crucial for optimizing chromatographic methods and reducing peak broadening.