A Complete Guide to Guard Columns, Benefits, Applications, and Best Practices

High-Performance Liquid Chromatography (HPLC) delivers reliable separation and quantification across pharmaceuticals, biological samples, natural products,

Home » HPLC Frit

Specification :

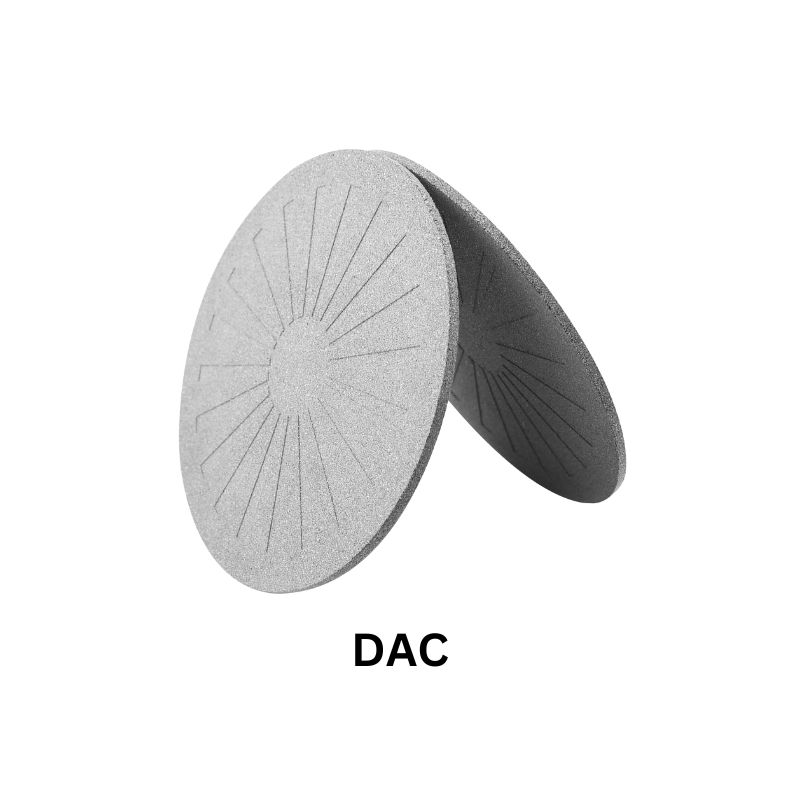

Sintered Metal Disc Filter with OEM Pore Size Peek or PCTFE Circle

1.) 316L Stainless Steel for UHPLC, Pore Size: 0.2μ, 0.5μ, 2μ, 5μ, 10μ, 20μ OEM Option

2.) Peek or PCTFE Circle Board

3.) Diameter OEM Size

OD : 6.4 / 6.5 / 14.4 / 19.1 / 22.4 / 38.0mm

ID : 1.6 / 2.4 / 3.2 / 12.0 / 15.8 / 19.0 / 33.0 mm

H: 1.6 / 2.0mm

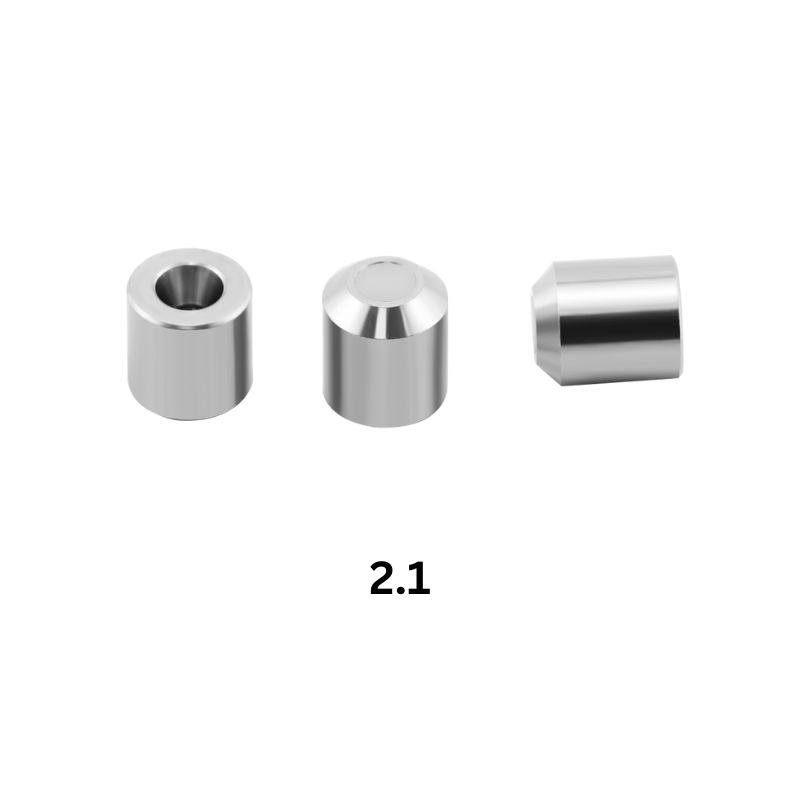

Specification :

1.) 316L Stainless Steel for UHPLC, Pore Size: 0.2μ, 0.5μ, 2μ

2.) Peek for option for Pore Size: 2μ

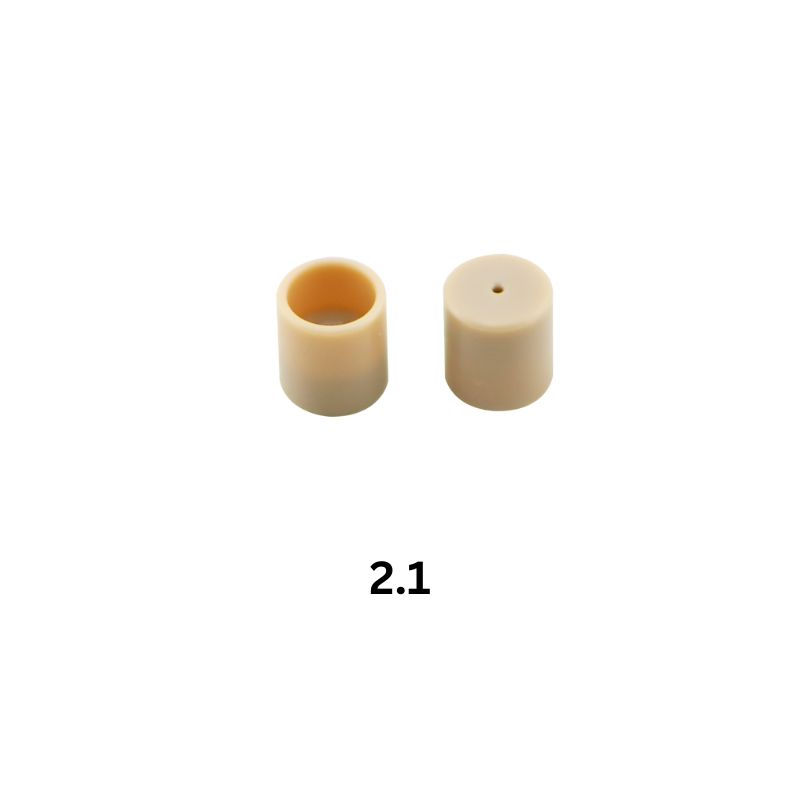

Specification :

1.) 316L Stainless Steel for UHPLC, Pore Size: 0.2μ, 0.5μ, 2μ

2. ) Peek for option for Pore Size: 2μ

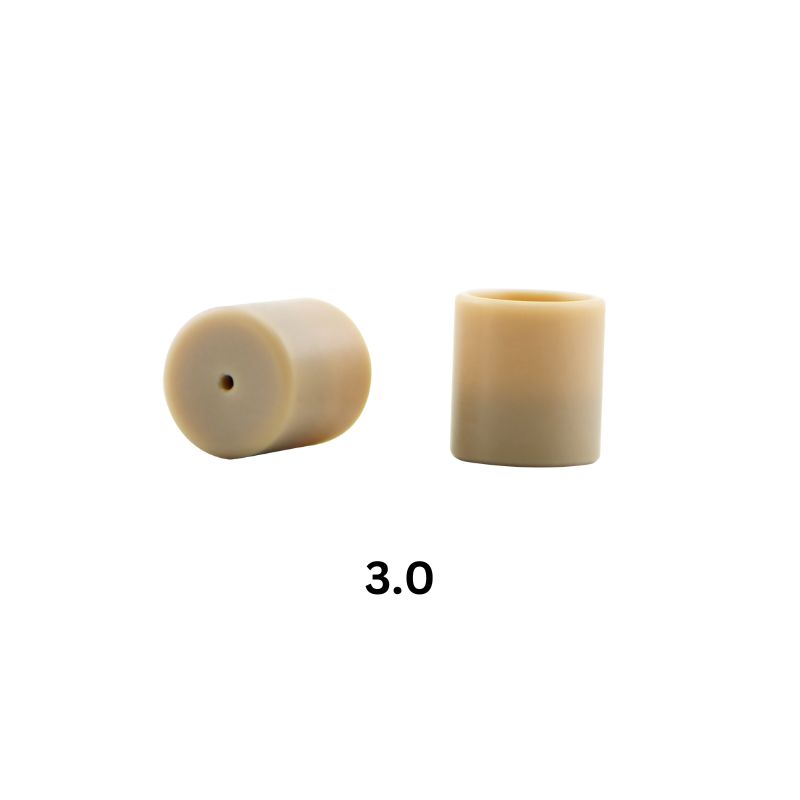

Specification :

Peek Pore Size: PEEK Big Hole: 0.5μ, 2μ, 5μ, 10μ, 15μ, 20μ

Materials

1. 316L Stainless Steel , PEEK

2. Pore Size: 0.5μ, 2μ, 5μ, 10μ, 15μ, 20μ

PEEK Big Hole: 0.5μ, 2μ, 5μ, 10μ, 15μ, 20μ

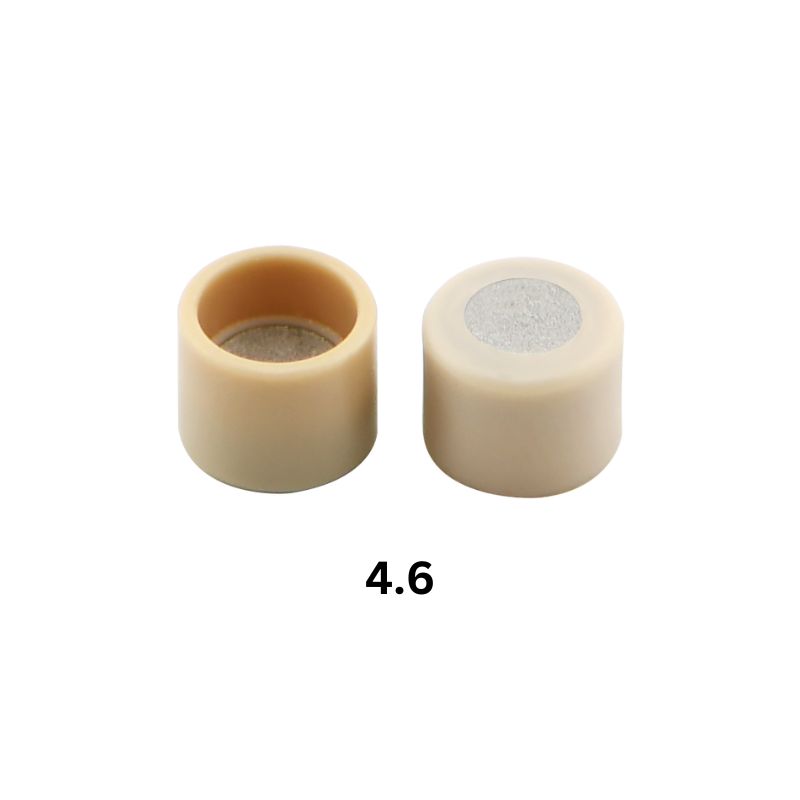

Specification :

1. PEEK Frit: 0.5μ, 2μ, 5μ, 10μ, 15μ, 20μ

2. PEEK Filter: 0.5μ, 2μ, 5μ, 10μ, 15μ, 20μ

PEEK Big Hole: 0.5μ, 2μ, 5μ, 10μ, 15μ

Specification :

1. 316L Stainless Steel for UHPLC, Pore Size: 0.5μ, 2μ, 5μ, 10μ, 15μ, 20μ, 30μ, 40μ,

2. Pore Size OEM Available

As a trusted professional OEM supplier of HPLC Column Frit, we, uHPLCs, are committed to providing high-quality HPLC frit and services that exceed our customers’ expectations. Our focus on precision and accuracy for laboratory applications is why we use only the best materials and advanced manufacturing techniques to produce our Ultra High Performance Liquid Chromatography column frits.

We understand the challenges scientists and researchers face when seeking to accurately analyze data. That’s why we’ve developed different size frits designed to deliver the highest levels of performance and reliability if Lab Applications.

Our column frits are fully tested and proven to provide excellent efficiency, resolution, and peak symmetry, making them ideal for complex sample matrices. We offer a wide range of column frits in various pore sizes and materials to suit different applications.

Our experts collaborate closely with clients to fully understand their specific needs and provide tailored solutions that align with their individual requirements.

We prioritize timely delivery, fast turnaround times, and competitive pricing, establishing us as the preferred HPLC Frit professional OEM supplier for customers globally.

uHPLCs is recognized as a dependable and professional OEM supplier of HPLC frits, offering high-quality column frit HPLC designed for outstanding performance and precision in laboratory settings.

Partner with us to enhance your research with our superior products and exceptional service, and elevate your research outcomes to the next level.

Upgrade your HPLC system with our top-quality Column Frits.

The Elite Team Behind HPLC Column Hardware Production

The Pioneers of HPLC Column Hardware Manufacturing

The Leading Professionals of HPLC Column Hardware Design

High Quality HPLC Column 316L, 316 Stainless Steel Powder Materials

Design New HPLC Columns 100% As Clients Request

Make HPLC Column Samples And Test Before Mass Products.

High Quality HPLC Column 316L, 316 Stainless Steel Tube Materials

Design New HPLC Columns 100% As Clients Request

Make HPLC Column Samples And Test Before Mass Products.

In High-Performance Liquid Chromatography (HPLC), a frit is a porous filter or barrier located at the entrance and/or exit of the chromatographic column. Its main purpose is to prevent particles and debris from entering the column, which could potentially cause clogging and negatively impact the separation process.

The frit is usually made of a porous material, such as stainless steel or PEEK (Polyether Ether Ketone), and acts as a physical barrier while still allowing the mobile phase (solvent and sample) to pass through smoothly. It ensures that only the dissolved analytes in the sample are introduced into the column for separation and analysis, while particulates and larger contaminants are retained outside the column.

The use of a frit is essential to maintain the optimal performance and longevity of the HPLC column, as well as to obtain reliable and accurate analytical results. Regular maintenance and replacement of the frit are necessary to prevent any potential blockages that could affect the chromatographic performance.

As We Know, The HPLC column frit is a crucial component that plays a significant role in the chromatographic process. Here are the main features of an HPLC column frit:

The frit is designed to have controlled porosity, allowing the mobile phase (solvent and sample) to pass through while preventing particles and contaminants from entering the column. It acts as a filter, ensuring only the dissolved analytes enter the separation process.

Frits are typically made of materials that are chemically inert and compatible with a wide range of solvents and samples. Stainless steel and PEEK (Polyether Ether Ketone) are commonly used materials due to their stability and resistance to corrosion.

The frit is designed to effectively retain and prevent particles from passing into the column. This feature ensures the column remains free from blockages, which could otherwise affect the chromatographic performance.

The size of the frit’s pores is carefully chosen based on the specific requirements of the HPLC column and the type of analysis being performed. The frit’s size affects the flow rate and backpressure of the system, making it important to select the appropriate frit dimensions for optimal performance.

The frit material must be compatible with the mobile phase, sample, and the stationary phase of the HPLC column. Compatibility ensures there are no unwanted interactions that could interfere with the separation process.

The frit should be manufactured with high precision to maintain uniformity in porosity and particle retention across the entire surface. A consistent and well-made frit ensures reliable and reproducible chromatographic results.

The frit is subject to wear and tear over time due to its continuous use. To ensure the longevity of the column and maintain consistent performance, it is essential to inspect and replace the frit regularly.

uHPLCs’ HPLC column frits designed for easy replacement. This allows chromatographers to perform routine maintenance efficiently and minimize downtime in the analysis process.

Overall, the HPLC column frit is a critical component that contributes to the effectiveness and reliability of the chromatographic separation process. Its proper design and maintenance are essential for obtaining accurate and reproducible analytical results in high-performance liquid chromatography.

In High-Performance Liquid Chromatography (HPLC), there are primarily two types of frits used at the entrance and/or exit of the chromatographic column:

These frits are made of stainless steel, a durable and chemically resistant material. Stainless steel frits are commonly used in HPLC columns, particularly in analytical and preparative HPLC systems. They come in various porosities and can withstand high pressures and aggressive solvents, making them suitable for a wide range of applications.

PEEK frits are made from a high-performance polymer known for its excellent chemical resistance and mechanical properties. These frits are particularly popular in modern HPLC systems due to their biocompatibility and compatibility with a broader range of solvents and pH conditions. PEEK frits are often used in HPLC columns designed for biomolecule analysis.

Both types of frits serve the same fundamental purpose of retaining particles and contaminants while allowing the mobile phase and sample analytes to pass through for chromatographic separation. The choice between stainless steel and PEEK frits depends on factors such as the type of analysis, solvent compatibility, and the specific needs of the HPLC system. Regular maintenance and replacement of the frits are essential to ensure optimal performance and reliable results in HPLC analyses.

The column frit in HPLC (High-Performance Liquid Chromatography) is of utmost importance due to the following reasons:

Particle Retention: The frit acts as a physical barrier that prevents particles and debris from entering the HPLC column. If these particles were to pass into the column, they could cause blockages, leading to chromatographic issues and affecting the quality of analytical results.

Column Protection: By keeping contaminants away from the column packing material, the frit helps protect the integrity and longevity of the HPLC column. The column is a critical and often expensive component, so preserving its performance and lifespan is crucial for cost-effective and reliable analyses.

Enhanced Efficiency: A properly functioning frit ensures a smooth flow of the mobile phase through the column while retaining the sample’s dissolved analytes. This efficient separation process allows for accurate identification and quantification of the compounds in the sample.

Consistency and Reproducibility: A clean and well-maintained frit ensures consistent flow rates and pressure within the system, leading to reproducible results between different runs. Reproducibility is a fundamental requirement in analytical chemistry to validate the accuracy of the analysis.

Minimized Downtime: Regularly replacing and maintaining the frit can help prevent unexpected column blockages during analysis, reducing downtime and the need for troubleshooting or column replacement.

Sample Purity: The frit keeps larger particles and contaminants away from the column, ensuring that only the desired components of the sample are analyzed. This feature is especially crucial when dealing with complex samples that may contain impurities or other unwanted components.

Sensitivity and Sensibility: A clean frit reduces the chance of interference with the analytes of interest, improving the sensitivity of the HPLC system to detect and quantify low-level compounds accurately.

Analytical Accuracy: By preventing unwanted contaminants from entering the column, the frit helps maintain the accuracy of the analysis. This is essential in various applications, such as pharmaceutical quality control, environmental monitoring, and food safety analysis.

In summary, the HPLC column frit plays a vital role in maintaining the column’s performance, preserving sample integrity, and ensuring the accuracy and reproducibility of analytical results. By acting as a protective barrier and allowing only the desired analytes to pass through, the frit is a critical component in achieving reliable and high-quality chromatographic separations.

After You Get the New HPLC Frit, And Changing the frit in an Agilent HPLC column is a routine maintenance task that helps ensure the column’s optimal performance. Here We List a step-by-step guide on how to change the frit in an Agilent HPLC column:

* Remove the HPLC column from the system and set it on a clean and flat surface.

* Ensure that the column is empty and free from any solvent or sample.

* Using tweezers or needle-nose pliers, carefully grip the old frit at the column’s exit or entrance.

* Gently pull the old frit out of the column. Be cautious not to damage the column’s packing material while doing this.

Take the new PEEK frit and cut a small section of PEEK tubing with a PEEK tubing cutter or sharp scissors.

The length of the PEEK tubing should be slightly longer than the inner diameter of the column.

Insert one end of the PEEK tubing into the column, ensuring that it goes all the way to the bottom.

Use tweezers or pliers to gently press the frit further into the column until it is securely seated.

If there is any excess PEEK tubing sticking out of the column, use the PEEK tubing cutter or sharp scissors to trim it so that it aligns with the column’s exit or entrance.

Once the new frit is securely in place, reinstall the column back into the HPLC system.

Ensure that all connections are tight and secure.

Before using the column for analysis, flush it with an appropriate solvent to remove any air bubbles and to condition the column.

It’s important to follow proper laboratory safety protocols while handling HPLC columns and equipment. Additionally, refer to the manufacturer’s instructions or user manual for your specific Agilent HPLC column model for any additional guidelines or recommendations regarding frit replacement.

HPLC frits are commonly used in the chromatography industry for a wide range of applications, including sample filtration and injection, column protection, and flow control.

These small porous blocks, typically made from stainless steel or ceramic, serve as a filter for any unwanted particles or debris in the sample, ensuring optimal separation of the sample components during the chromatography process. Here are some common product applications for HPLC frit:

1. Sample filtration and injection – HPLC frits help remove particulate matter from samples before they are injected into the system.

2. Column protection – HPLC frits are used to prevent damage to the chromatography column by trapping unwanted debris.

3. Drug Discovery: HPLC is an essential tool for drug discovery research, as it provides a means for separating and analyzing complex mixtures of compounds. HPLC frits are used in a variety of drug discovery applications

4. Flow control – Frits are used to regulate the flow rate of the mobile phase and ensure optimal performance of the column.

5. Environmental Monitoring: HPLC frits play a critical role in environmental monitoring, as they are used to separate and analyze a wide range of environmental contaminants. This helps to ensure that water and soil are safe for human consumption and other uses.

6. Sample preparation – HPLC frits are used in sample preparation to remove unwanted contaminants and ensure accuracy in subsequent testing.

7. Mass spectrometry – Frits are also used in mass spectrometry applications to prevent ions from entering the detector and interfering with results.

8. QA/QC Laboratories: HPLC frits are widely used in QA/QC laboratories to ensure the quality and safety of products. They are used to analyze a variety of samples, including pharmaceuticals, food, and cosmetics.

9. In-Vitro Diagnostics: HPLC frits are also used in in-vitro diagnostic applications, where they are used to analyze blood, urine, and other biological samples. This helps to diagnose and monitor a variety of medical conditions, including cancer and infectious diseases.

some questions about HPLC Frit you and others like to know

HPLC frits are small, porous disks that are used to filter and trap particles in chromatographic columns. They are typically made of stainless steel or ceramic materials and are used to protect the column from particulate matter that could damage the stationary phase.

In summary, HPLC frits are essential components of HPLC columns and filters, playing a vital role in achieving optimal chromatographic performance. By understanding their functions, materials, and selection criteria, you can ensure the efficient and reliable operation of your HPLC system.

HPLC frits are used in drug discovery to separate and analyze complex mixtures of compounds. By using HPLC frits, researchers can identify and isolate specific compounds of interest, which can then be further studied for potential therapeutic applications. and as we know, there are 3 main purpose, please check as following:

HPLC frits fulfill several crucial purposes within the drug discovery process:

Drug discovery involves identifying and isolating promising drug candidates from a vast pool of potential compounds. HPLC, with its high resolution and sensitivity, allows researchers to separate these complex mixtures and analyze individual components effectively. Frits play a vital role in this process by:

Once promising drug candidates are separated, frits help in their further characterization and evaluation:

HPLC frits are crucial for maintaining quality control and monitoring throughout the drug discovery process:

Overall, HPLC frits are invaluable tools in drug discovery, contributing to efficient compound separation, characterization, quality control, and advancement of promising drug candidates for further research and development.

HPLC frits are used in environmental monitoring to separate and analyze a wide range of environmental contaminants. By using HPLC frits, researchers can identify and quantify contaminants in water and soil samples, which helps to ensure that these resources are safe for human consumption and other uses.

HPLC frits are used in QA/QC laboratories to ensure the quality and safety of products. They are used to analyze a variety of samples, including pharmaceuticals, food, and cosmetics, to ensure that they meet specific quality standards and regulatory requirements.

HPLC frits are used in in-vitro diagnostic applications to analyze biological samples, such as blood and urine, for the presence of specific biomarkers. By using HPLC frits, researchers can diagnose and monitor a variety of medical conditions, including cancer and infectious diseases.

HPLC frits should be replaced on a regular basis to ensure the integrity of the column and the accuracy of the results. The frequency of replacement will depend on the specific application and the type of frit used, but in general, frits should be replaced every 50-100 injections.

Choosing the right HPLC frit depends on a variety of factors, including the sample matrix, the flow rate, and the column dimensions. It is important to consult with an expert in chromatography to determine the best frit for your specific application.

With some experience from our HPLC expert, The frequency of replacing HPLC frits varies depending on several factors, including:

* Type of frit: Different materials have different lifespans. Stainless steel frits typically last longer than PEEK or PTFE frits.

* Pressure used: High pressure can degrade frits faster than low pressure.

* Nature of samples and mobile phases: Samples with high particle content or aggressive mobile phases can clog frits quickly.

* Frequency of use: Columns used more frequently may require more frequent frit replacement.

* Stainless steel frits: Every 6-12 months or when the system pressure increases significantly.

* PEEK frits: Every 3-6 months or when the system pressure increases significantly.

* PTFE frits: Every 1-3 months or when the system pressure increases significantly.

* Increased system pressure: This is the most common sign of a clogged frit.

* Decreased peak resolution: A clogged frit can cause peaks to broaden and merge together.

* Change in peak shape: A distorted peak shape can indicate a partially blocked frit.

* Increased baseline noise: This can be caused by contamination from a damaged frit.

* Use high-quality filters to remove particles from your samples and mobile phases.

* Flush your columns regularly with appropriate solvents.

* Avoid using harsh chemicals on your frits.

* Inspect your frits regularly for signs of damage.

Remember, replacing a frit is a relatively inexpensive procedure. It is better to replace a frit too often than to risk damaging your column or compromising your results.

Contact uHPLCs Today for Any Questions for HPLC / UHPLC

High-Performance Liquid Chromatography (HPLC) delivers reliable separation and quantification across pharmaceuticals, biological samples, natural products,

Introduction Ever struggled to decide which HPLC column to use for your analysis? You’re not

Introduction Ever wondered how scientists ensure your medicine is pure, or your drinking water is

Introduction Food safety is a critical priority for both manufacturers and regulators. Beyond protecting public

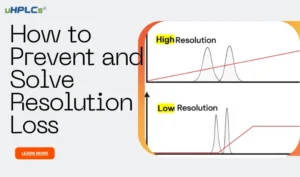

Introduction In High-Performance Liquid Chromatography (HPLC), resolution is a key factor that determines the ability

Uridine 5’-triphosphate Trisodium Salt (UTP-Na₃) Reference Standard | CAS 19817-92-6 | High-Purity Reference Materiel Product Code: U-D25015X Chemical Name: Uridine 5’-triphosphate Trisodium Salt (UTP-Na₃) Category:

Glutathione (G-SH) Reference Standard | CAS 70-18-8 | High-Purity Reference Materiel Product Code: G-D25016X Chemical Name: Glutathione (G-SH) Category: Drug Impurity Standard CAS Number: 70-18-8

Adenosine 5’-triphosphate Disodium Salt Reference Standard | CAS 987-65-5 | High-Purity Reference Materiel Product Code: A-D25014X Chemical Name: Adenosine 5’-triphosphate Disodium Salt Category: Drug Impurity

WhatsApp us

Subscribe for exclusive offers and updates on new arrivals