Dead Volume and its Role in HPLC Systems

In high-performance liquid chromatography (HPLC), dead volume refers to the overall volume of the system that the mobile phase flows through but doesn’t contribute to the separation process. Think of it as the nooks and crannies – tubing, fittings, injector chamber, detector flow cell – where the mobile phase stagnates or moves sluggishly, causing analytes to spend extra time outside the separation column.

Dead volume plays a crucial role in HPLC because it broadens and distorts chromatographic peaks, impacting resolution and sensitivity.

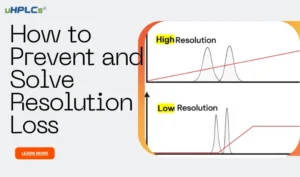

How Dead Volume Affects Peak Shape and Resolution

Imagine injecting a sharp band of sample onto the column. Ideally, it should travel through the column and elute as a narrow peak at the detector. However, the presence of dead volume leads to several negative effects:

- Band broadening: When analytes spend additional time in the dead volume, they spread out, resulting in wider peaks. This reduces the resolution between overlapping peaks, making it harder to distinguish them.

- Tailing: The analytes interact with surfaces in the dead volume, causing them to elute slower than the main peak. This creates a tailing peak, further reducing resolution.

- Reduced peak height: Broadened and tailed peaks have lower amplitudes, leading to decreased sensitivity and difficulty in quantification.

The Relationship Between Dead Volume and System Efficiency

System efficiency in HPLC is related to its ability to separate analytes effectively. Higher efficiency translates to narrower peaks and better resolution. Dead volume negatively impacts efficiency by broadening peaks and decreasing resolution. Minimizing dead volume is therefore crucial for optimizing HPLC performance.

Common Peak Constraints in HPLC Analysis

HPLC analysis aims to achieve clean, well-defined peaks for accurate identification and quantification of analytes. However, various peak constraints can arise, distorting peak shapes and hindering analysis. Understanding these constraints is crucial for optimizing your HPLC run and obtaining reliable results.

1.Description of Peak Constraints and their Impact on Analysis

Peak constraints represent factors that deviate an ideal peak from a perfect Gaussian shape, impacting resolution, sensitivity, and information extraction.

The major types of peak constraints include:

- Peak broadening: Analytes spend extended time within the system due to band widening (e.g., diffusion in dead volume, slow mass transfer in the stationary phase). This leads to broad, overlapping peaks, compromising resolution.

- Tailing: Interactions between analytes and surfaces (e.g., active sites on the stationary phase) cause delays for some molecules, resulting in asymmetric peaks with elongated tails. Tailing reduces both resolution and peak height.

- Fronting: Conversely, some analytes may interact weakly with the stationary phase, eluting faster than expected. This results in sharpened peaks with leading shoulders or “fronts,” again affecting resolution and peak area integration.

- Splitting: Certain solutes can separate into multiple peaks due to multiple binding modes within the stationary phase or specific interactions with mobile phase components. This complicates peak identification and quantification.

These constraints affect analytical accuracy in various ways:

- Reduced resolution: Overlapping peaks become difficult to distinguish, leading to misidentification and inaccurate quantification.

- Diminished sensitivity: Broadened or shortened peaks have lower amplitudes, impacting detectability and the signal-to-noise ratio.

- Quantification errors: Distorted peak shapes make accurate integration of peak areas for quantification challenging.

2. Examples of Peak Constraints

- Peak broadening: In gradient elution, analytes encounter a changing solvent environment within the column, potentially causing band spreading due to varying binding strengths.

- Tailing: Ionizable analytes in a poorly buffered mobile phase can interact with active sites on the stationary phase, generating tailing.

- Fronting: Highly hydrophobic analytes may interact weakly with the stationary phase, eluting too early and causing fronting.

- Splitting: Isomers and other structurally similar analytes can sometimes exhibit splitting due to differential interactions with the stationary phase.

3. Challenges of Managing Peak Constraints in High-throughput Environments

High-throughput environments demand rapid analysis with numerous samples. However, managing peak constraints in such scenarios can be challenging:

- Limited time: Shortened run times might exacerbate peak constraints due to faster injections and elution profiles.

- Increased sample diversity: Variations in analyte properties across different samples can pose optimization challenges for a single HPLC method.

- Automation reliance: Automated systems require robust methods that are less susceptible to peak distortions under varying sample loads and operating conditions.

In conclusion:

- Understanding peak constraints is crucial for interpreting HPLC data and ensuring accurate analysis.

- Various strategies exist to minimize these constraints, such as optimizing mobile phase composition, adjusting flow rates, and selecting appropriate columns and detection methods.

- Managing peak constraints in high-throughput settings requires careful method optimization and potentially adopting advanced techniques like hyphenated chromatography-mass spectrometry.

The Advantages of Larger Dead Volume

While generally considered detrimental in HPLC, a larger dead volume can, in specific situations, offer unexpected benefits. Optimizing your system based on these advantages requires careful consideration and balancing against the well-known drawbacks.

1. Explaining the Benefits of Larger Dead Volume

In certain circumstances, increased dead volume can be advantageous:

- Improved peak integration: For analytes with very narrow peaks, particularly in low-concentration samples, a slightly larger dead volume can spread the peak slightly, making integration and quantification more accurate.

- Delayed separation onset: In gradient elution, a larger dead volume provides analytes with additional time in the initial isocratic conditions. This can be beneficial for resolving poorly retained peaks that elute before the gradient has fully developed, especially when analyzing complex samples with diverse retention times.

- Temperature control: For temperature-sensitive analytes, a larger flow cell volume in the detector provides a more stable thermal environment, minimizing peak distortions due to temperature fluctuations.

- Sample pre-mixing: Some applications may require pre-mixing of the sample with reagents or internal standards before separation. A larger injection loop or injector chamber with increased dead volume can facilitate effective pre-mixing, ensuring homogeneity before entering the column.

2. Case Studies or Examples of Benefits

- Analyzing trace-level impurities: When quantifying very low concentrations of impurities in high-purity samples, a slightly broadened peak due to increased dead volume can improve integration accuracy compared to an extremely narrow peak with a low signal-to-noise ratio.

- Gradient elution of complex environmental samples: In analyses of environmental samples containing diverse organic compounds with varying polarities, a larger dead volume can allow poorly retained early eluting peaks to resolve before the gradient fully develops, leading to improved separation and identification.

- Temperature-sensitive protein analysis: For temperature-sensitive proteins, using a larger flow cell detector with increased dead volume can provide a more stable thermal environment, minimizing peak distortions and ensuring accurate analysis without degradation.

3. Balancing Dead Volume with Other Factors

While strategically increasing dead volume can offer benefits, it’s crucial to balance this with other factors:

- Resolution: Remember that dead volume generally reduces resolution by broadening peaks. Increasing it beyond a beneficial point can significantly compromise separation of closely eluting analytes.

- Flow rate: Adjusting the flow rate can mitigate the negative effects of increased dead volume. A higher flow rate compensates for the slower analyte movement in the larger volume, maintaining reasonable analysis times.

- Column dimensions: Opting for longer or narrower columns can partially counteract the broadening effect of a larger dead volume, maintaining good resolution even with slightly increased void volume.

Strategies for Optimizing Dead Volume in HPLC Systems

Dead volume presents a constant challenge in HPLC, but various strategies can help you minimize its impact and achieve optimal results.

1. Practical Tips for Managing Dead Volume:

- Hardware:

- Utilize short, narrow-bore tubing throughout the system. Smaller internal diameters offer less volume for mobile phase stagnation.

- Choose low-volume connectors and fittings. Minimize the number of connections to reduce dead volume contribution.

- Invest in low-dead-volume injector loops and low-volume detector flow cells. Consider specialized designs, like fingertight connections, for faster tubing changes.

- Regularly maintain and clean the system to prevent buildup in tubing and fittings, which can exacerbate dead volume effects.

- Software:

- Optimize injection volumes to be around 1-5% of the column void volume. Avoid overloading the column, which worsens peak broadening.

- Adjust flow rates strategically. Higher flow rates can partially compensate for increased dead volume by reducing the time spent within it.

- Optimize gradient elution profiles to ensure sufficient time for separation before the initial isocratic conditions are completely replaced.

2. Techniques for Adjusting Dead Volume to Navigate Peak Constraints:

- Peak broadening: In rare cases where peak broadening is beneficial (e.g., trace-level analysis), slightly increase dead volume by using wider-bore tubing or larger tubing lengths. However, carefully balance this with the potential loss of resolution.

- Tailing: Experiment with mobile phase additives and pH adjustments to minimize interactions between analytes and the stationary phase. Consider alternative stationary phases with different binding properties.

- Fronting: Optimize mobile phase composition and flow rate to strengthen interactions between analytes and the stationary phase. Explore different column chemistries or gradient profiles for improved retention.

3. Innovations in HPLC Design and Technology:

- Integrated microfluidic chips: These devices miniaturize the entire HPLC system, significantly reducing dead volume and enabling faster analysis with improved resolution.

- Nano-LC: Utilizing columns with very small diameters further minimizes dead volume, achieving excellent resolution for complex samples with minimal solvent consumption.

- Smart injectors: Advanced injection systems can minimize sample dispersion and reduce dead volume contribution at the injection point.

- Integrated pre-treatment modules: Coupling sample pre-treatment steps directly to the HPLC system minimizes sample transfer and associated dead volume issues.

In conclusion:

- Managing dead volume effectively requires a combination of hardware, software, and analytical techniques.

- Understanding your specific needs and constraints helps you determine the optimal balance between minimizing dead volume and maintaining good resolution.

- Embrace new technologies and innovative designs to further optimize your HPLC system and achieve the best possible analytical results.

Applications and Case Studies

Question:

A new batch of A brand liquid phase purchased inside a pharmaceutical plant to do a certain project out of the peak is bifurcation, which the engineer tossed many times at home, has not been solved. Next to another S brand of the old liquid phase to do the same project, the peak is no problem.

When everyone was at their wits’ end, someone had a bright idea to connect the tubing from the injector to the column on the old S-liquid phase to the new A-liquid phase, and the failure magically disappeared. Later, we found that the volume of the tubing of the old liquid phase was much larger than that of the new liquid phase. This brings us to a phenomenon completely contrary to our common sense in chromatography. The larger the dead volume is, the better the peak is?

To understand this phenomenon, I think you must first talk about the solvent effect in the liquid phase.

If you have experience in the liquid phase, you may have heard of this name, and you may know that the solvent effect can affect the peak shape of the liquid phase. So what is the solvent effect? How can we avoid the interference of the solvent effect?

The solvent effect, as the name implies, refers to the effect of the solvent used to dissolve the sample on the chromatographic results.

To understand it more deeply, we have to start with how the sample enters the liquid chromatography column. The sample we want to analyze is transferred into the injection vial after a series of pretreatments, dilutions, and volume determinations. The autosampler takes a certain sample volume (e.g. 20 µl) and injects it into the liquid phase system. The sample we are talking about here is the sample molecule we want to analyze and the solvent used to dissolve the diluted sample molecule.

Subsequently, the mobile phase pushes the sample, travels through the line between the injector and the column, and enters the column. The sample solvent is carried away by the mobile phase. In contrast, the sample molecules undergo continuous adsorption and desorption between the stationary and mobile phases inside the column. Finally, they run out of the column into the detector and are detected, forming peaks.

If the sample solvent and the initial mobile phase are the same, then the process is the same as described above, and there will be no problems. However, what if they are not the same? Then the reality is not so simple. If you use a liquid phase method where the initial conditions are 10% acetonitrile-water as the mobile phase, the sample is dissolved in 100% acetonitrile.

The sample enters the liquid phase system and quickly comes to the head of the lc column. Then the sample begins to partition between the stationary phase and the mobile phase, while the sample solvent is carried away by the mobile phase.

Let’s compare the three sample molecules ABC in different positions. The movement of molecule A in the column at the beginning is under the condition of a 10% mobile phase.

And the movement of molecules B and C at the beginning occurs under conditions where the solvent is the mobile phase. And relatively speaking, C has the longest movement time under this condition. 100% acetonitrile has a much stronger elution capacity than 10%, which results in the initial movement of the chromatographic column head. C runs faster, B a little slower, and A the slowest.

This directly leads to the disruption of the uniform distribution of the sample molecules at the beginning of the HPLC column separation, resulting in a variety of peak problems such as precession, off-tailing and splitting at the final peak. We can also see that if the elution strength of the sample solvent is higher than the mobile phase, C will run faster than A, and the solvent effect will be more pronounced.

If the sample volume is larger, the solvent effect will be more obvious because, in this case, the mobile phase will take longer to remove the solvent completely.

So from here, we can also summarize how to avoid or mitigate the solvent effect on the chromatographic peak.

– Try to use the initial mobile phase as the solvent for the sample, or use a solvent with an elution strength close to the initial mobile phase to dissolve the sample.

– However, there are times when pure organic solvents must be used to dissolve certain samples, and we can also use a reduced injection volume to reduce the solvent effect.

– Another trick is to increase the tubing volume between the injector and the column or add a mixer. The goal is to give the mobile phase enough space and time to dilute the sample solvent as much as possible with the mobile phase before the sample enters the column. This way, after the sample enters the column, the sample solvent has been diluted enough not to cause solvent effects.

In the story mentioned at the beginning, the bifurcation of the peaks was solved after replacing a larger pipeline volume for this very reason.

Perhaps at this point, some curious students will ask, “What if I use a solvent with weaker elution capacity than the initial mobile phase? Will the solvent effect also occur?

Besides the different elution strengths, what other factors contribute to the solvent effect? Let’s save these questions and talk to you about them another time.

Ever encountered a chromatography mystery that left you scratching your head? This blog post dives into a real-life case where peak bifurcation in a new liquid phase threw a project into chaos, only to be unexpectedly solved by a seemingly inconsequential change.

Hope those information are helpful for your understand more for the dead volume advantage.