Introduction

In High Performance Liquid Chromatography (HPLC), peak shape is more than just visual—it directly reflects method performance and data reliability. Among various distortions, peak tailing is one of the most common and problematic, often indicating issues with system configuration, sample properties, or column condition. This guide provides a clear and practical roadmap to understanding the causes of tailing, their impacts, and how to troubleshoot them in routine analytical settings.

What Are Tailing Peaks?

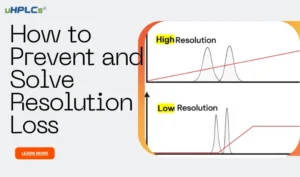

In ideal HPLC analysis, chromatographic peaks should be symmetric and Gaussian. A tailing peak, by contrast, is asymmetric with a prolonged slope on the trailing side (right side). Tailing can affect the accuracy of peak integration, decrease resolution, and lead to poor reproducibility.

The USP Tailing Factor (Tf) is commonly used to quantify tailing:

Tf=2f / W0.05

Where:

W0.05: Peak width at 5% of peak height

f: Distance from the peak maximum to the front of the peak at 5% height

A Tf value close to 1.0 is optimal. Values above 2.0 are generally considered unacceptable in analytical methods requiring high precision.

Why Do Tailing Peaks Matter?

Even minor tailing can have significant impacts:

Resolution degradation: Tailing overlaps neighboring peaks, compromising separation.

Quantitative inaccuracy: Asymmetric peaks yield unreliable area calculations.

Reduced method robustness: Increased sensitivity to small changes in method conditions.

Regulatory risks: Poor system suitability may lead to method failure in GMP/GLP settings.

Common Causes of Tailing Peaks

1. Column-Related Issues

●Column Degradation

-Old or contaminated columns lose efficiency.

-Solution: Replace or regenerate the column.

●Improper Column Chemistry

-Mismatched stationary phase for the analyte (e.g., using C18 for highly polar compounds).

-Solution: Select a suitable column (e.g., HILIC for polar compounds).

●Void Formation

-Gaps at the column inlet due to poor packing or pressure shocks.

-Solution: Replace the column or use a guard column.

2. Mobile Phase Issues

●Incorrect pH or Buffer Strength

-Improper pH can cause secondary interactions (e.g., silanol effects in basic compounds).

-Solution: Adjust pH (e.g., pH ~2-3 for acidic compounds, pH ~7-8 for basic compounds).

●Inadequate Solvent Strength

-Weak elution strength leads to slow analyte release.

-Solution: Optimize gradient or isocratic conditions.

●Buffer Salts Precipitation

-Poor solubility causes blockages.

-Solution: Use compatible buffers (e.g., phosphate, acetate).

3.Sample-Related Issues

●Overloading

Excessive sample concentration saturates the column.

Solution: Dilute the sample or reduce injection volume.

●Sample Solvent Mismatch

Stronger solvent than mobile phase causes band broadening.

Solution: Use a solvent weaker than or equal to the mobile phase.

●Matrix Effects

Complex samples (e.g., biological extracts) can interfere.

Solution: Improve sample cleanup (SPE, filtration).

4. Instrumental Issues

●Extra-Column Band Broadening

Long tubing, large detector cell volume, or poor connections.

Solution: Minimize dead volume with narrow-bore tubing.

●Detector Time Constant Too High

Slow detector response distorts peak shape.

Solution: Reduce time constant (if adjustable).

How to Troubleshoot Tailing Peaks

Step 1: Confirm Peak Tailing

●Calculate the Tailing Factor (Tf)

Tf= W 0.05 / 2A

W0.05= Peak width at 5% height

A = Distance from peak front to apex at 5% height

Tf > 1.2 indicates significant tailing.

●Compare with Previous Runs

Has tailing appeared suddenly, or is it a persistent issue?

Check system suitability records for historical trends.

Step 2: Check the Column

A. Column Condition

●Symptoms:

Increased backpressure

Peak broadening over time

Loss of theoretical plates (N)

●Solutions:

Flush the column with a strong solvent (e.g., 100% ACN or MeOH for reversed-phase).

Replace the column if performance does not improve.

B. Column Chemistry Mismatch

●Symptoms:

Persistent tailing for certain analytes (e.g., basic compounds on C18).

●Solutions:

Switch to a more suitable column:

Basic compounds? → Use polar-embedded or charged surface hybrid (CSH) columns.

Acidic compounds? → Ensure proper pH control (~pH 2-3).

Add silanol suppressors (e.g., 0.1% triethylamine for basic analytes).

Step 3: Evaluate the Mobile Phase

A. pH and Buffer Selection

●For Basic Compounds:

Silanol interactions cause tailing.

Solution: Lower pH (~2-3) to protonate silanols.

●For Acidic Compounds:

Ionization at high pH leads to tailing.

Solution: Keep pH below pKa (e.g., pH 4-5).

●Buffer Concentration Too Low?

Solution: Increase buffer strength (10-50 mM).

B. Organic Modifier Strength

●Weak elution strength → Analyte lingers on the column.

●Solution: Increase organic modifier (e.g., ACN or MeOH) by 5-10%.

C. Contaminated or Degraded Mobile Phase

●Symptoms:

Ghost peaks, baseline noise, inconsistent retention.

●Solution:

Prepare fresh mobile phase.

Use HPLC-grade solvents and high-purity buffers.

Pro Tip: Use a Ghost Peak Trap Column to Eliminate Baseline Surprises

If you’re seeing unexpected ghost peaks, even after preparing fresh mobile phases and cleaning your system, the culprit might be contaminants leaching from the HPLC system itself—such as tubing, injector seals, or solvents. In such cases, installing a ghost peak trap column between the pump and injector can make a significant difference.

This specialized guard column is designed to adsorb system-generated impurities before they reach your analytical column, ensuring a cleaner baseline and more consistent retention times.

At uHPLCs, we provide high-capacity ghost peak trap columns compatible with most systems and solvents. They’re especially valuable in trace analysis and stability studies, where sensitivity and reproducibility are critical.

Benefits:

-

Removes system-derived contaminants

-

Reduces ghost peaks and baseline drift

-

Prolongs the lifespan of your main column

-

Enhances overall data quality

Want to know if a ghost peak trap is right for your method? Talk to our technical team—we’re happy to help you optimize your setup.

Step 4: Assess Sample-Related Issues

A. Sample Overloading

●Symptoms:

Tailing worsens with higher concentrations.

●Solution:

Dilute the sample or reduce injection volume.

Rule of thumb: Injection volume ≤ 5% of column volume.

B. Solvent Strength Mismatch

●Strong injection solvent (e.g., 100% ACN in a weak mobile phase).

●Solution: Match injection solvent to initial mobile phase composition.

C. Matrix Effects

Complex samples (e.g., plasma, plant extracts) can cause tailing.

Solution: Improve sample cleanup (SPE, protein precipitation, filtration).

Step 5: Instrumental & Hardware Checks

A. Extra-Column Band Broadening

Causes: Long tubing, large detector cell volume, loose fittings.

Solutions:

Use shorter, narrower tubing (0.12-0.17 mm ID).

Check for leaks or poor connections.

B. Detector Settings

Too slow time constant → Peak distortion.

Solution:

Reduce detector time constant (if adjustable).

C. Inlet Frit Blockage

Symptoms:

Rising backpressure, distorted peaks.

Solution:

Replace inlet frit or use a guard column.

Step 6: Method Optimization (If All Else Fails)

●Adjust Gradient Conditions (steeper gradients for late-eluting peaks).

●Change Column Temperature (higher temps reduce viscosity and improve kinetics).

●Use Additives (e.g., ion-pairing reagents for ionic compounds).

Column Selection Tips to Avoid Tailing

Not all columns are created equal — and choosing the right one can make or break your peak shape. If tailing is a recurring issue, your stationary phase chemistry might be to blame. Here’s how to make smarter choices:

1. Choose end-capped columns for basic compounds.

Uncapped or poorly end-capped silica columns often have free silanol groups that interact with protonated bases, leading to tailing. Fully end-capped C18 or C8 phases reduce these interactions significantly.

2. Consider polar-embedded or polar-endcapped phases.

For analytes with strong polarity or ionizable groups, columns like phenyl-hexyl, amide, or polar-embedded C18 phases offer better control over secondary interactions.

3. For ionizable compounds, match column chemistry with mobile phase pH.

A mismatch between your column’s surface chemistry and your mobile phase conditions (especially pH) can worsen peak tailing. Always consider the pKa of your analyte and the column’s pH stability range.

4. Use specialty columns for sticky or problematic analytes.

Analytes like amines, acids, or peptides may need columns specifically designed to reduce silanol or metal-ion interactions — such as hybrid-silica columns or those with deactivated surfaces.

Pro Tip: Always consult your column manufacturer’s application notes. They often include test data on tailing factors under various conditions — saving you time (and frustration).

uHPLCs provides a wide selection of high-quality reversed-phase and specialty columns, engineered for excellent peak symmetry and reproducibility, even with challenging analytes.

Conclusion

Peak tailing is a common yet solvable challenge in HPLC. By understanding its causes and applying a systematic troubleshooting approach—ranging from column and mobile phase selection to instrument setup—analysts can ensure accurate, reproducible, and regulatory-compliant results.

If you’re still struggling with tailing peaks or unsure which column chemistry best suits your analytes, uHPLCs is here to help. We offer expert technical support and a diverse range of high-performance HPLC columns tailored for even the most challenging applications.

Whether you’re working with basic, acidic, or polar compounds, our column options are engineered for excellent peak symmetry, robust reproducibility, and long-term durability—helping you achieve cleaner baselines and more reliable data.

Need help troubleshooting your method? Looking for a column recommendation? Want to test a sample on one of our columns?

Get in touch with us today — let uHPLCs be your partner in solving chromatographic challenges.

Contact us at sales@uhplcs.com now to discuss your application, request a sample, or get personalized technical advice. Your perfect peak starts here.