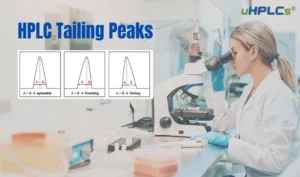

HPLC Tailing Peaks All You Like to Know

What is Tailing Peaks in HPLC System ? High-Performance Liquid Chromatography (HPLC) is a versatile

Home » Empty Chromatography Columns

| Types | Inner diameter (mm) | Length (mm) | Frits (µm) | Material | Component |

|---|---|---|---|---|---|

| Analytical HPLC Columns | 2.1 | 30 | 2 | 316 L stainless steel tubing complete with end-fitting | 1 Empty column + 1 Top plug + 1 end cap + 1 pcs ( 2 µm frits, nuts, and ferrules. ) |

| Analytical HPLC Columns | 3.0 | 50 | 2 | 316 L stainless steel tubing complete with end-fitting | 1 Empty column + 1 Top plug + 1 end cap + 1 pcs ( 2 µm frits, nuts, and ferrules. ) |

| Analytical HPLC Columns | 4.0 | 75 | 2 | 316 L stainless steel tubing complete with end-fitting | 1 Empty column + 1 Top plug + 1 end cap + 1 pcs ( 2 µm frits, nuts, and ferrules. ) |

| Analytical HPLC Columns | 4.6 | 100 | 2 | 316 L stainless steel tubing complete with end-fitting | 1 Empty column + 1 Top plug + 1 end cap + 1 pcs ( 2 µm frits, nuts, and ferrules. ) |

| Analytical HPLC Columns | 7.8 | 150 | 2 | 316 L stainless steel tubing complete with end-fitting | 1 Empty column + 1 Top plug + 1 end cap + 1 pcs ( 2 µm frits, nuts, and ferrules. ) |

| Analytical HPLC Columns | 10.0 | 200 | 2 | 316 L stainless steel tubing complete with end-fitting | 1 Empty column + 1 Top plug + 1 end cap + 1 pcs ( 2 µm frits, nuts, and ferrules. ) |

| Preparative HPLC Columns | 20.0 | 250 | 2 | 316 L stainless steel tubing complete with end-fitting | 1 Empty column + 1 Top plug + 1 end cap + 1 pcs ( 2 µm frits, nuts, and ferrules. ) |

| Preparative HPLC Columns | 30.0 | 300 | 2 | 316 L stainless steel tubing complete with end-fitting | 1 Empty column + 1 Top plug + 1 end cap + 1 pcs ( 2 µm frits, nuts, and ferrules. ) |

| Preparative HPLC Columns | 50.0 | 500 | 2 | 316 L stainless steel tubing complete with end-fitting | 1 Empty column + 1 Top plug + 1 end cap + 1 pcs ( 2 µm frits, nuts, and ferrules. ) |

Specification( Customizable)/ Size | Materials | Applications |

2.1mm ×30mm ; 2.1×50mm ; 2.1×75mm ; 2.1×100mm ; 2.1×125mm ; 2.1×150mm; 2.1×200mm ; 2.1×250mm ; 2.1×300mm | 316L Stainless Steel | Analytical |

3.0 ×30mm ; 3.0×50mm ; 3.0×75mm ; 3.0×100mm ; 3.0×125mm ; 3.0×150mm ; 3.0×200mm ; 3.0×250mm ; 3.0×300mm ; | 316L Stainless Steel | Analytical |

4.0×20mm ; 4.0×30mm ; 4.0×50mm ; 4.0×100mm 4.0×150mm ; ; 4.0×200mm; 4.0×250mm ; 4.0×300mm | 316L Stainless Steel | Analytical |

4.6×20mm ; 4.6×30mm ; 4.6×50mm ; 4.6×100mm 4.6×150mm ; 4.6×200mm ; 4.6×250mm ; 4.6×300mm | 316L Stainless Steel | Analytical |

7.8×150mm ; 7.8×250mm ; 7.8×300mm | 316L Stainless Steel | Semi-prep |

10×50mm ; 10×100mm ; 10×150mm 10×200mm ; 10×250mm ; 10×300mm | 316L Stainless Steel | Semi-prep |

20×50mm ; 20×100mm ; 20×150mm ; 20×200mm 20×250mm ; 20×300mm | 316L Stainless Steel | Semi-prep |

21.2×150mm ; 21.2× 250mm | 316L Stainless Steel | Semi-prep |

Achieving High-Precision Results in Chromatography with uHPLCs’ Empty HPLC Columns. Trust HENGKO for your HPLC column needs and take your chromatography to the next level, Contact uHPLCs Wholesale Empty HPLC Column today !

We use state-of-the-art technology and advanced equipment to manufacture our columns and employ strict quality control measures to ensure our products are of the highest caliber. Our team is also dedicated to continuously improving our processes and staying current with the latest developments in the industry.

With a focus on expertise and Dedication, uHPLCs’ professional empty chromatography columns factory team is committed to helping our customers achieve the most accurate and precise results in their chromatography experiments. Trust uHPLCs for your HPLC Column needs.

uHPLCs is a professional OEM factory specializing in producing Empty Chromatography Columns. With years of experience in the industry, we have established ourselves as a trusted and reliable supplier of high-quality HPLC columns. Our state-of-the-art facility is equipped with the latest technology and advanced equipment, allowing us to produce empty HPLC columns that meet the highest quality and performance standards.

HENGKO’s OEM Empty Chromatography Columns are meticulously crafted from high-purity 316L stainless steel tubing. These precision-machined columns, easy to pack and equipped with a 2.0 µm frit cap, can operate at pressures up to 15,000 psi (1034 bar).

These columns are available in a wide array of sizes, accommodating needs ranging from analytical to preparative applications.

The columns feature extremely low dead volumes, smoothly finished inner tube walls, and uniformly rounded cross-sections. These attributes ensure high-performance, consistency, and reproducibility in the finished columns.

The stainless steel column heads of these empty HPLC columns are of paramount importance. They secure the sieve plate that connects the column to the chromatography system and provide a leak-proof seal. The heads are designed to minimize dead zones, dead volumes, and unnecessary extra-column volumes, failure of which could lead to broad peaks and decreased column efficiency.

The column headers are engineered to offer negligible dead and extra-column volumes along with leak-free seals. Composed of three parts – an inner connector, a column tube connector, and a rear nut – these headers ensure secure attachment of the frit and the column to the chromatography system. The inner connector links the column tube to the system, while the rear nut fastens the inner connector to the empty column. A metal ring keeps the lc column tubing connector and the empty column in place.

All these empty HPLC columns can be tailored according to your specific requirements. Up to this point,

Our custom-made empty columns have included the following HPLC types:

Empty HPLC column is a type of column manufactured by a third-party company and sold to be used in another company’s HPLC system. The column is typically sold without any packing material or stationary phase, allowing users to customize it to their specific needs by adding their packing material.

The column dimensions, including the length, internal diameter, and particle size, should be compatible with the HPLC system.

The user should consider the type of stationary phase they want to use in the column and ensure that it is compatible with the column’s dimensions and the sample being analyzed.

The column should handle the HPLC system’s pressure and flow rate requirements and the sample being analyzed.

The column should have a reasonable lifetime, and the user should consider the cost of the column over its lifetime.

The user should consider the column performance, including efficiency, resolution, and selectivity.

The user should consider the quality of the column, including the materials used, manufacturing, and the supplier’s reputation.

The user should consider the warranty offered by the supplier and how it will be dealt with if there are any issues or problems with the column.

The user should consider the level of technical support offered by the supplier and how easy it will be to get help if needed.

High Quality HPLC Column 316L, 316 Stainless Steel Tube Materials

Design New HPLC Columns 100% As Clients Request

Make HPLC Column Samples And Test Before Mass Products.

In Short, Empty chromatography columns refer to columns used in chromatographic techniques, such as liquid chromatography (LC) or gas chromatography (GC), which have not been filled with any stationary phase or packing material. These columns are typically made of glass or metal and come in various sizes to accommodate different sample volumes.

In chromatography, the column is a crucial component that allows the separation of components in a mixture based on their differential interactions with the stationary phase and mobile phase (solvent). The stationary phase is a material with specific properties that help in separating the analytes of interest, while the mobile phase carries the sample through the column.

Before performing chromatographic separations, the columns need to be prepared and packed with the appropriate stationary phase. The choice of stationary phase depends on the specific application and the properties of the analytes being separated. After packing, the column is then connected to the chromatography system, and the sample is introduced for analysis.

Empty chromatography columns are essentially “blank” and cannot perform any separation until they are packed with the required stationary phase. Packing the columns is a critical step in chromatography to ensure optimal separation efficiency and resolution during the analysis process.

The use of empty chromatography columns (columns without the stationary phase) offers several advantages in the field of chromatography:

Flexibility in Stationary Phase Selection: Empty columns allow chromatographers to choose and pack the most suitable stationary phase for their specific separation needs. Different stationary phases exhibit varying selectivity and interactions with analytes, enabling fine-tuning of separations for optimal results.

Customizable Separation: With empty columns, researchers can create customized chromatographic methods tailored to their analytical goals. They can modify the mobile phase composition, flow rates, and other parameters to achieve desired separation outcomes.

Cost-Effectiveness: Empty columns are typically less expensive than pre-packed columns, making them a cost-effective option, especially when dealing with a wide range of analytes or when multiple columns with different stationary phases are required.

Method Development and Optimization: Empty columns are invaluable during method development stages. They allow scientists to explore and optimize various separation conditions without the need to commit to a specific stationary phase upfront. This process enhances method robustness and accuracy.

Stationary Phase Screening: When working with complex samples, screening multiple stationary phases becomes essential for obtaining the best separation. Empty columns enable the assessment of different stationary phases before investing in larger quantities or specialized columns.

Education and Training: In educational settings, empty columns serve as practical tools for teaching chromatography principles, including the column-packing process, which is an essential skill for chromatography practitioners.

Quality Control and Assurance: Empty columns are useful for quality control testing of new or refurbished chromatography columns. Ensuring that columns meet specific performance criteria before packing guarantees consistent and reliable results during analyses.

Sample Preconcentration: Empty columns can be employed for sample preconcentration to increase sensitivity and enhance detection limits. Preconcentrating samples before injection can be beneficial when analyzing trace-level compounds.

Sustainable Practice: Reusing empty columns after proper cleaning and regeneration promotes a sustainable approach in the laboratory by reducing waste and minimizing the environmental impact.

Column Storage: Empty columns are also convenient for storage purposes. They provide a secure way to preserve columns when not in use, protecting them from dust and potential contamination.

Overall, empty chromatography columns offer versatility, cost-effectiveness, and the ability to adapt to specific analytical needs. They play a critical role in method development, optimization, and quality control, making them essential tools in the chromatographer’s arsenal.

As We Know, Empty chromatography columns, before being packed with the stationary phase, have various applications in chromatography and related laboratory processes. Some of the key applications are:

Column Preparation: Empty columns are used to prepare chromatography columns with specific stationary phases tailored to the separation needs. Scientists carefully select and pack the appropriate stationary phase based on the characteristics of the analytes they want to separate.

Method Development: Before running actual samples, chromatographers often develop and optimize separation methods. Empty columns facilitate method development by allowing scientists to test different stationary phases and mobile phase compositions to achieve the desired separation efficiency and resolution.

Stationary Phase Screening: In certain cases, it may be necessary to screen and compare different stationary phases for a particular separation. Empty columns are used to evaluate the effectiveness of different stationary phases before committing to a specific one.

Quality Control: Empty columns are utilized to verify the performance and reproducibility of newly manufactured or refurbished chromatography columns. Quality control tests ensure that the column meets the required specifications before being packed and released for analytical use.

Educational Purposes: In chromatography courses and training laboratories, empty columns are used to teach students about the column-packing process and the fundamentals of chromatography.

Maintenance and Cleaning: During the lifetime of a chromatography column, it may require maintenance, cleaning, or replacement of the stationary phase. Empty columns are essential for these tasks, ensuring that the column is in optimal condition for subsequent analyses.

Method Validation: Before introducing a new method into routine use, it is essential to validate its performance. Empty columns can be employed to validate the method’s suitability and reproducibility before analyzing real samples.

Sample Preconcentration: In some cases, researchers may use empty columns to preconcentrate analytes from a large volume of sample before injecting it into the chromatographic system. This technique enhances sensitivity and detection limits.

In summary, empty chromatography columns play a vital role in method development, stationary phase screening, quality control, education, and maintenance within the field of chromatography. They are a necessary starting point for preparing columns that can efficiently separate and analyze various compounds in complex mixtures.

As following are some application of Empty Chromatography Columns, You can make packing by yourself based on your lab special requirements.

In short, An Empty Chromatography Columns is a column that has not been filled with any stationary phase and is, therefore, not capable of performing any separation or analysis.

To properly store an empty HPLC column, follow these steps:

Here are some additional tips for storing empty HPLC columns:

By following these tips, you can help to ensure that your empty HPLC columns remain in good condition and last for many years.

Yes, an empty High-Performance Liquid Chromatography (HPLC) column can be reused, as long as it is in good condition and has not been contaminated during previous use. Reusing empty HPLC columns is a common practice in chromatography laboratories to save costs and reduce waste. However, there are some important considerations to keep in mind:

Column Condition: The column should be inspected for any signs of physical damage, such as cracks or leaks, before reuse. Damaged columns may not perform optimally and can lead to unreliable results.

Cleaning and Regeneration: Prior to reuse, the column needs to be thoroughly cleaned and regenerated. This process involves flushing the column with appropriate solvents to remove any residual contaminants or analytes from previous runs. Proper cleaning and regeneration help restore the column’s performance.

Stationary Phase Compatibility: The stationary phase inside the column should be compatible with the analytes to be separated in subsequent runs. If the previous analysis used a specific stationary phase that is not suitable for the new separation, it may be necessary to repack the column with the appropriate stationary phase.

Method Compatibility: Ensure that the column is suitable for the method and application you intend to use. Different columns have different characteristics, such as particle size, pore size, and column length, which can impact separation performance.

Column Storage: If not reusing the column immediately, store it properly to prevent contamination and damage. Columns should be stored in a clean, dry environment, and it’s a good practice to use end caps to protect the column ends.

Performance Verification: After cleaning and before reuse, it’s advisable to perform a test run using known standard compounds to verify that the column’s performance has been restored and that it provides acceptable separation and resolution.

Column Longevity: Over time, columns degrade with use, and their performance may decline. Eventually, even with proper care, columns will reach the end of their useful life and may need to be replaced.

By following these guidelines and taking proper care of the HPLC column, it is possible to reuse it multiple times while maintaining satisfactory separation performance. However, it’s essential to monitor column performance regularly and replace the column when it no longer meets the required separation criteria.

Analytical empty columns are used for analytical purposes, such as to identify and quantify the components of a mixture. Preparative empty columns are used for preparative purposes, such as to purify or isolate compounds from a mixture.

Here is a table that summarizes the key differences between analytical and preparative empty columns:

| Feature | Analytical empty column | Preparative empty column |

|---|---|---|

| Purpose | Identification and quantification of components in a mixture | Purification or isolation of compounds from a mixture |

| Column diameter | Narrower (typically 2.1-4.6 mm) | Wider (typically 10-50 mm) |

| Column length | Shorter (typically 25-150 mm) | Longer (typically 150-500 mm) |

| Stationary phase | Finely divided particles (typically 3-10 µm) | Larger particles (typically 10-50 µm) |

| Flow rate | Lower (typically 0.1-1.0 mL/min) | Higher (typically 1.0-10 mL/min) |

| Sample size | Smaller (typically µL-mL) | Larger (typically mL-L) |

In general, analytical empty columns are used for small samples and require longer run times, while preparative empty columns are used for larger samples and require shorter run times.

Here are some examples of applications for analytical and preparative empty columns:

Analytical empty columns:

Preparative empty columns:

Cleaning an empty High-Performance Liquid Chromatography (HPLC) column is a crucial step to remove any residual contaminants or analytes from previous runs before reuse or storage. The cleaning procedure may vary depending on the nature of the compounds previously separated and the column material. Here is a general guide on the best way to clean an empty HPLC column:

Flush with Mobile Phase Solvent:

Gradient Wash:

Backflushing:

pH Adjustment:

Wash with Organic Solvent:

Final Rinse:

Flow Rate and Time:

Verify Cleanliness:

Always follow the manufacturer’s guidelines for cleaning and maintaining your specific type of HPLC column. If the column shows signs of degradation, poor performance, or persistent contamination, it may be more practical to replace the column rather than attempting to clean it extensively. Proper care and regular maintenance of the column can extend its life and ensure reliable results in your chromatographic analyses.

When conditioning an empty HPLC column, you’d better flush with a small amount of the mobile phase used in the analysis because this helps to wet the column and prepare it for use.

There are a few ways to know or find out when your HPLC column is empty:

You can also use a column test kit to determine if your column is empty. Column test kits typically contain a mixture of known compounds that are used to assess the performance of the column. If the column is empty, the test compounds will elute from the column quickly and without resolution.

If you are unsure whether or not your column is empty, it is best to consult with an HPLC expert.

Here are some tips for increasing the lifespan of your HPLC columns:

By following these tips, you can help to ensure that your HPLC columns last for many years.

An empty HPLC column cannot be used for analytical purposes as it has no stationary phase to separate the compounds.

An empty HPLC column can be damaged if it is not handled or stored properly. Physical damage, such as scratches or dents, can cause the column to leak or malfunction. The Empty HPLC Column should also be protected from extreme temperatures and high pressures.

An empty HPLC column cannot be used for sample preparation as it has no stationary phase for separation or purification.

To check if an HPLC column is still good to use after being stored empty, you can perform a test run with a sample known to elute at a specific retention time. If the sample elutes at the expected time, the column is likely still in good condition.

Yes, an empty HPLC column can be used with different mobile phases. Still, it should be properly cleaned and conditioned before switching to a new mobile phase to ensure optimal performance.

Using an empty HPLC column for analysis will result in no separation or purification of the sample, and the results will not be accurate or meaningful. It can also lead to damage to the column or instrumentation.

No, an empty HPLC column cannot be used for preparative HPLC. Preparative HPLC columns are packed with a stationary phase that is designed to retain and separate large quantities of sample. Empty HPLC columns do not contain a stationary phase, so they are not suitable for preparative HPLC applications.

Here are some of the reasons why an empty HPLC column cannot be used for preparative HPLC:

If you need to perform preparative HPLC, you must use a preparative HPLC column that is packed with a suitable stationary phase.

Here are some tips for choosing the right preparative HPLC column for your application:

Contact uHPLCs Today for Any Questions for HPLC / UHPLC

What is Tailing Peaks in HPLC System ? High-Performance Liquid Chromatography (HPLC) is a versatile

Introduction High-Performance Liquid Chromatography (HPLC) is a powerful analytical technique widely used in various fields,

HPLC Size Exclusion is one of special and important HPLC Column, so today, we gather

Introduction HPLC (High-Performance Liquid Chromatography) is a powerful analytical technique used to separate, identify, and

Superior Quality, On-demand Customization,Continuous Optimization,

Strictly control the manufacturing process,

Intimate Service, Go All Out.

WhatsApp us

Subscribe for exclusive offers and updates on new arrivals