Ever wondered why those peaks on your HPLC chromatogram look a little off? Asymmetry, broadening, or even extra peaks can all be signs of trouble. These “peak shape issues” can significantly impact the accuracy and reliability of your analysis.

Here’s why achieving a perfect peak shape is crucial:

- Clarity: Well-shaped peaks allow for clear separation of different components in your sample. Distorted peaks can overlap, making it difficult to quantify each one accurately.

- Precision: Asymmetry or broadening can affect how we measure peak area, a key factor in determining the amount of a particular compound present.

- Reliability: Consistent peak shapes ensure consistent results. Deviations can indicate problems with the analysis, leading to unreliable data.

The good news? Innovative solutions like uHPLC’s Peak Smooth Column and Ghost Buster Column are here to help. We’ll delve deeper into these advancements and how they can revolutionize your HPLC analysis by ensuring pristine peak shapes for trustworthy results.

Understanding HPLC Peak Shape Issues

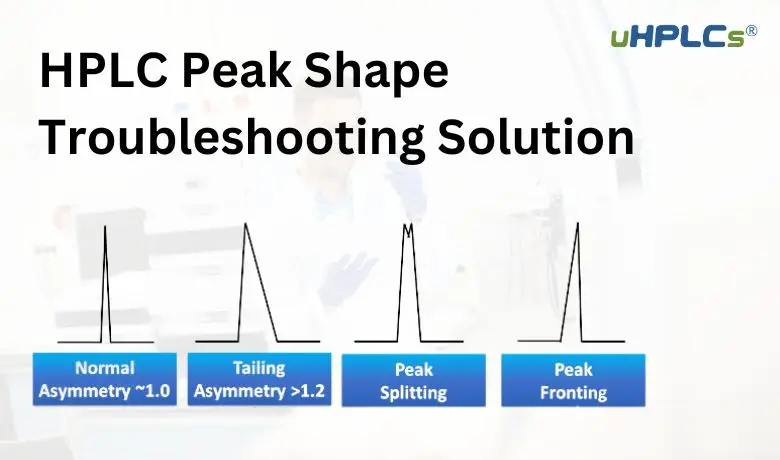

a peak represents a specific compound separated from a mixture. The ideal peak shape is symmetrical, resembling a bell curve. This symmetrical peak shape is crucial because it allows for accurate measurement and interpretation of the data. Deviations from this ideal shape indicate problems with the separation process and can significantly impact your analysis.

IHere’s a breakdown of some common peak shape problems and their significance:

IHere’s a breakdown of some common peak shape problems and their significance:

Tailing peaks: These peaks have a broad, drawn-out tail on the right side. This can be caused by interactions between the analyte and the stationary phase, weak mobile phase conditions, or overloaded columns. Tailing hinders the separation of closely eluting peaks, making them appear merged.

Fronting peaks: The opposite of tailing, fronting peaks have a sharp front edge but a broad, leading shoulder. This can be caused by injection volume issues, improper mobile phase composition, or secondary interactions with the injector. Fronting can also make it difficult to distinguish between closely eluting compounds.

Split peaks: A single compound appearing as two separate peaks. This can be caused by a phenomenon called “peak splitting,” which can arise from interactions with the stationary phase or overloaded columns. Split peaks complicate quantification and identification of the compound.

Broad peaks: Peaks that are wider than expected can be caused by various factors like column inefficiency, mobile phase viscosity, or sample overloading. Broad peaks reduce resolution and decrease the sensitivity of the analysis.

Ghost peaks: These are extra peaks appearing in the chromatogram that don’t correspond to any actual components in the sample. They can be caused by contamination in the mobile phase, system carryover, or problems with the detector. Ghost peaks can mask real peaks and lead to misinterpretations.

Causes of Peak Shape Issues

General Troubleshooting Tips

Now that we understand the different types of peak shape problems, let’s explore the underlying causes behind them. These factors can be broadly categorized into three areas: column, mobile phase, and instrumental issues.

Column-related factors:

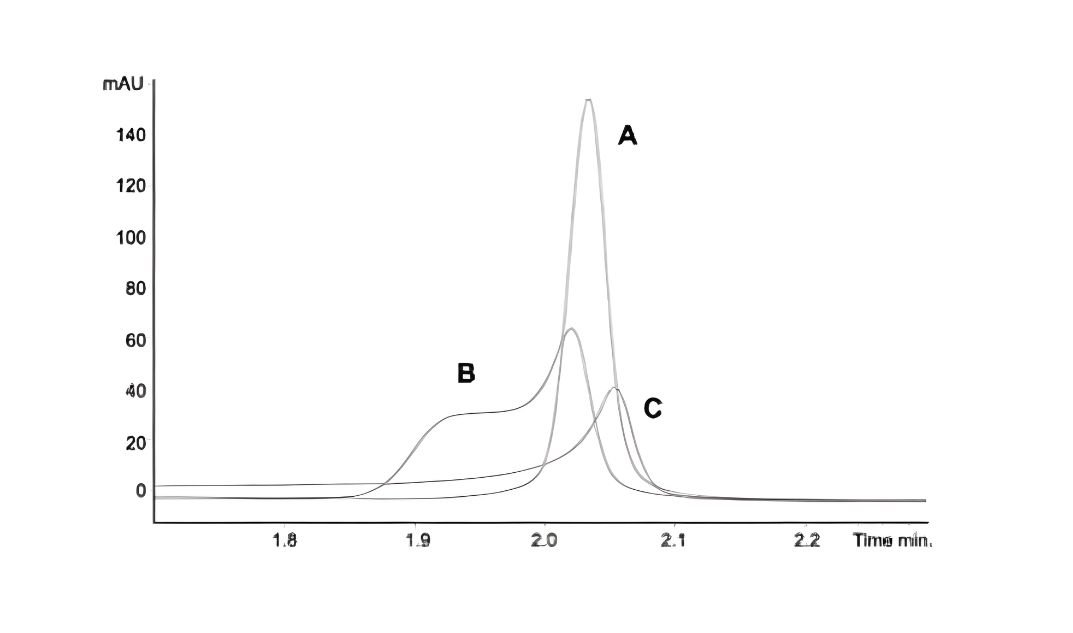

- Column overloading: Injecting too much sample onto the column can overwhelm its capacity, leading to broad peaks and decreased resolution.

HPLC column overloading peak shape

HPLC column overloading peak shape

- Column contamination: Build-up of impurities or sample components within the column can cause tailing peaks and ghost peaks.

- Inappropriate column selection: Using a column with the wrong stationary phase or particle size for your analytes can result in various peak shape issues.

Mobile phase-related factors:

- Incorrect pH: The pH of the mobile phase significantly influences the interaction between analytes and the stationary phase. Inappropriate pH can lead to tailing or fronting.

- Inadequate solvent strength: If the mobile phase isn’t strong enough to elute certain analytes efficiently, they may spend too much time interacting with the stationary phase, causing broad peaks.

- Poor solvent mixing: Incomplete mixing of mobile phase components can create inconsistencies in the separation process, leading to variations in peak shapes.

Instrumental factors:

- Flow rate inconsistencies: Fluctuations in the flow rate of the mobile phase can cause peak broadening and decreased resolution.

- Temperature fluctuations: Changes in temperature can affect the interaction between analytes and the stationary phase, resulting in peak shape variations.

- Detector issues: Malfunctioning detectors can produce distorted peak shapes or even ghost peaks.

By understanding these causes and their effects on peak shapes, you can effectively troubleshoot your HPLC analysis and achieve optimal separation and accurate results.

Achieving perfect peak shapes in HPLC requires a keen eye and a systematic approach. Here are some general troubleshooting tips to help you combat these issues:

Column Care is Key: Regularly inspect your column for signs of contamination and replace it when necessary. Following proper cleaning procedures can extend its lifespan and prevent peak shape problems.

Mobile Phase Matters: The mobile phase composition and pH play a crucial role in peak shape. Experiment with different solvent combinations and pH adjustments to find the optimal conditions for your specific analytes.

Maintaining the Machine: Regular instrument maintenance ensures optimal performance. Check for leaks, replace worn-out parts, and ensure proper flow rates and temperature control. A well-maintained instrument will contribute significantly to achieving consistent and desirable peak shapes.

Sample Prep Pays Off: Appropriate sample preparation techniques like filtration or centrifugation can minimize matrix effects and prevent contamination that could lead to peak shape issues. A clean sample is essential for a clean chromatogram.

By implementing these general tips and delving deeper into specific solutions like uHPLC’s innovative columns, you can transform your HPLC analysis, achieving pristine peak shapes for reliable and trustworthy results.

uHPLCs' Solutions for Peak Shape Troubleshooting

Choosing the Right Column for Your Needs

The quest for flawless peak shapes in uHPLC just got a boost with the introduction of the Peak Smooth Column. This innovative column technology tackles common peak shape problems head-on, ensuring sharper separations and more reliable results.

Peak Smooth Column: A Closer Look

The Peak Smooth Column boasts a specially designed stationary phase that minimizes unwanted interactions between analytes and the column surface. This translates to several key features:

- Enhanced surface chemistry: The stationary phase is engineered to offer a more uniform and consistent surface, reducing tailing and improving peak symmetry.

- Improved analyte-phase interaction: The optimized surface interactions ensure more efficient separation of closely eluting compounds, minimizing peak broadening and overlapping.

- Reduced secondary interactions: The Peak Smooth Column minimizes secondary interactions that can cause peak splitting or ghost peaks, leading to cleaner chromatograms.

Conquering Peak Shape Challenges

The Peak Smooth Column effectively addresses a variety of common peak shape problems:

- Tailing peaks: By promoting more uniform analyte-phase interactions, the column reduces tailing, leading to sharper peaks and improved resolution.

- Broad peaks: The optimized stationary phase minimizes secondary interactions that can contribute to peak broadening, resulting in tighter, more defined peaks.

- Split peaks: The reduced secondary interactions and improved efficiency of the Peak Smooth Column help prevent peak splitting, ensuring accurate identification and quantification of analytes.

Benefits and Applications

The advantages of the Peak Smooth Column extend beyond sharper peaks:

- Improved resolution: Tighter peaks allow for better separation of closely eluting compounds, leading to more accurate analysis.

- Enhanced sensitivity: Reduced peak broadening improves detection sensitivity, allowing for quantification of lower concentrations.

- Reliable results: Consistent peak shapes ensure reliable and reproducible data, crucial for quantitative analysis.

The Peak Smooth Column finds application in a wide range of analytical tasks, particularly those involving:

- Complex mixtures: Separating and identifying closely related compounds in intricate samples.

- Low-level analytes: Detecting and quantifying trace components present in low concentrations.

- High-throughput analysis: Maintaining consistent peak shapes even when processing large numbers of samples.

By incorporating the Peak Smooth Column into your uHPLC workflow, you can achieve superior peak shapes, leading to more accurate, reliable, and efficient analysis. In the next section, we’ll explore another innovative uHPLC solution for peak shape challenges – the Ghost Buster Column.

When it comes to tackling peak shape issues in HPLC, selecting the right column is paramount. Here are some key factors to consider:

- Nature of the sample: Understanding the complexity of your sample and the analytes of interest is crucial. For instance, if you’re dealing with closely related compounds, a column promoting high resolution like the Peak Smooth Column might be ideal.

- Peak shape problems encountered: Identifying the specific peak shape issues you’re facing (tailing, fronting, etc.) will help guide your choice. The Peak Smooth Column excels at addressing tailing and broadening, while the Ghost Buster Column, as we’ll see next, is specifically designed for ghost peaks.

Peak Smooth vs. Ghost Buster: Choosing Your Champion

While both Peak Smooth and Ghost Buster Columns are uHPLC innovations for peak shape troubleshooting, they target distinct challenges:

Peak Smooth Column: This is your go-to solution for general peak shape issues like tailing, broadening, and split peaks. Its optimized stationary phase minimizes unwanted interactions, leading to sharper, more symmetrical peaks.

Ghost Buster Column: As the name suggests, this column is a specialist in eliminating ghost peaks. It incorporates unique stationary phase modifications that effectively suppress ghost peak formation caused by mobile phase impurities or system carryover.

Making the Winning Choice

The best column choice depends on your specific application and the peak shape problems you’re encountering:

- For general peak shape improvement, enhanced resolution, and broader applicability, the Peak Smooth Column is an excellent choice.

- If ghost peaks are your primary concern, the Ghost Buster Column offers a targeted solution for achieving cleaner chromatograms.

Conclusion

Addressing HPLC peak shape issues is essential for accurate and reliable analysis. Poor peak shapes can lead to incorrect results, compromising your data integrity.

uHPLCs offers two effective solutions: the Peak Smooth Column, which resolves issues like tailing and broad peaks, and the Ghost Buster Column, designed to eliminate ghost peaks. These columns ensure smooth, symmetrical peaks for better resolution and quantification.

For more information and assistance with peak shape troubleshooting, contact uHPLCs. by email sales@uhplcs.com

Our experts are ready to help you optimize your HPLC system for the best performance. Visit our website or reach out to us directly to learn more.