HPLC is a workhorse technique in analytical chemistry. It separates and identifies compounds in a mixture using a pressurized solvent and a specialized column packed with microscopic particles. Imagine a tiny maze specifically designed to trap certain molecules based on their size and interactions. The separated components are then detected, allowing scientists to determine their presence and quantity. HPLC plays a crucial role in various fields, including drug discovery, environmental monitoring, and food safety analysis.

However, even the most sophisticated equipment can be hampered by a seemingly simple issue: air bubbles. These tiny pockets of gas trapped within the HPLC column can wreak havoc on your analysis.

How Air Bubbles Disrupt the Flow:

- Uneven flow: Air bubbles act like roadblocks, disrupting the smooth flow of the solvent through the column. This can lead to uneven distribution of the sample and distorted peak shapes in the final results.

- Reduced efficiency: Bubbles decrease the effective surface area available for interaction between the sample and the stationary phase in the column. This translates to poorer separation and potentially missed peaks.

- Detector noise: Air bubbles can cause fluctuations in the detector signal, making it difficult to accurately identify and quantify components.

Taking Control: Effective Bubble Removal Techniques

This blog aims to equip you with the knowledge and techniques to effectively remove air bubbles from your HPLC column and ensure optimal performance for your analyses. We’ll delve into various methods, from proper solvent degassing to clever column manipulation tricks, to help you achieve clear and reliable results.

1. Understanding the Enemy - How Air Bubbles Form and Disrupt Your HPLC Analysis

Air bubbles, those unwelcome guests in your HPLC column, can originate from various sources, each with its own impact on your analysis. Here’s a closer look at how they form and the problems they cause:

The Genesis of Air Bubbles:

- Dissolved Gas: Liquids naturally hold dissolved gases like air. Changes in pressure and temperature during the HPLC process can cause these dissolved gases to come out of solution, forming bubbles. Imagine shaking a soda bottle and then rapidly opening it – the released bubbles are a similar phenomenon.

- Leaking Connections: Imperfect seals or loose fittings along the HPLC line can allow air to enter the system. Think of a leaky faucet; a tiny opening can lead to a continuous flow of air.

- Empty Reservoirs: Running the pump dry or with a low solvent level can cause cavitation, where the formation and collapse of bubbles damages the pump and introduces air into the system.

- Mobile Phase Preparation: Improper mixing techniques or using solvents that haven’t been degassed can introduce air bubbles directly into the mobile phase.

The Downstream Effects: How Bubbles Skew Your Results

The presence of air bubbles in your HPLC column disrupts the carefully orchestrated dance of separation. Here’s how they manifest in your results:

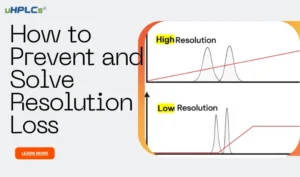

- Peak Distortion: Air bubbles act like tiny barriers, causing the sample components to flow unevenly through the column. This disrupts the normal elution pattern, leading to distorted peaks in the chromatogram. Imagine a traffic jam caused by a sudden road closure – the flow of cars (sample components) becomes uneven and unpredictable.

- Fluctuations in Baseline: Bubbles can cause fluctuations in the detector signal, resulting in a noisy baseline. Think of a flickering light instead of a steady stream – it becomes difficult to distinguish the actual signal from the background noise.

- Reduced Column Efficiency: A key goal of HPLC is to achieve good separation between components. Bubbles decrease the effective surface area available for interaction between the sample and the stationary phase. This translates to poorer separation, potentially leading to missed peaks or overlapping peaks that are difficult to quantify. Imagine a maze with blocked pathways – it becomes harder for the molecules to find their unique routes through the column.

Bubble-Prone Situations:

While air bubbles can form anytime, some situations create a more hospitable environment for them:

- Changes in Mobile Phase Composition: Switching solvents or using gradients (mixtures of solvents that change over time) can disturb the dissolved gas equilibrium, leading to bubble formation.

- High Flow Rates: Higher flow rates can increase the chance of air entering the system through leaks or by pulling dissolved gases out of solution.

- Column Temperature Fluctuations: Temperature changes, especially during column heating or cooling, can affect the solubility of gases, promoting bubble formation.

By understanding the origins and consequences of air bubbles, you’re well on your way to conquering them and achieving optimal performance in your HPLC analyses.

Detecting Air Bubbles in Your HPLC Column

Air bubbles might be microscopic, but their impact on your analysis can be loud and clear. Here’s how to identify their presence before they wreak havoc on your results:

The Power of Observation: Visual Inspection

The first line of defense is a good look-see. While directly inspecting the column itself might not be possible, some telltale signs can be observed:

- Visible bubbles in the solvent reservoir or tubing can indicate air entering the system.

- Frothing or bubbling in the solvent reservoir during mobile phase preparation suggests incomplete degassing.

Performance Speaks Volumes: Monitoring for Signs of Trouble

Even if bubbles remain unseen, their influence on your HPLC run can be detected through performance indicators:

- Increased baseline noise: A noisy baseline with erratic fluctuations can be a red flag for air bubble interference with the detector signal.

- Distorted peaks: Peaks appearing broader, tailing, or with uneven shapes can point towards uneven flow caused by air bubbles.

- Reduced peak height or area: Bubbles can decrease the effective concentration of the sample reaching the detector, leading to diminished peak responses.

- Unexplained changes in retention times: Air bubbles disrupting the flow path can cause slight variations in how long it takes for components to travel through the column.

Enlisting the Help of Specialized Tools:

While visual inspection and performance indicators offer valuable clues, there are more sophisticated tools available to confirm the presence of air bubbles:

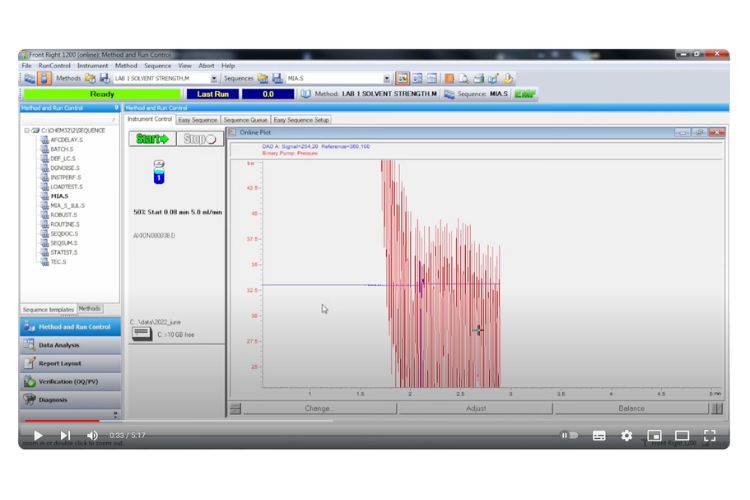

- Pressure monitoring: Sudden fluctuations in pressure can be indicative of air bubbles entering or collapsing within the system. Modern HPLC systems often have built-in pressure monitors that can be used for this purpose.

- Ultrasonic detectors: These detectors use high-frequency sound waves to detect changes in density within the mobile phase. Air bubbles, with their lower density compared to the liquid, can be identified using this technique.

By employing a combination of these methods, you can effectively detect air bubbles and take steps to eliminate them before they compromise your HPLC analysis.

Techniques for Removing Air Bubbles Step by Step

Air bubbles may be stubborn, but they’re not invincible. Here’s an arsenal of techniques to banish them from your HPLC column and restore smooth operation:

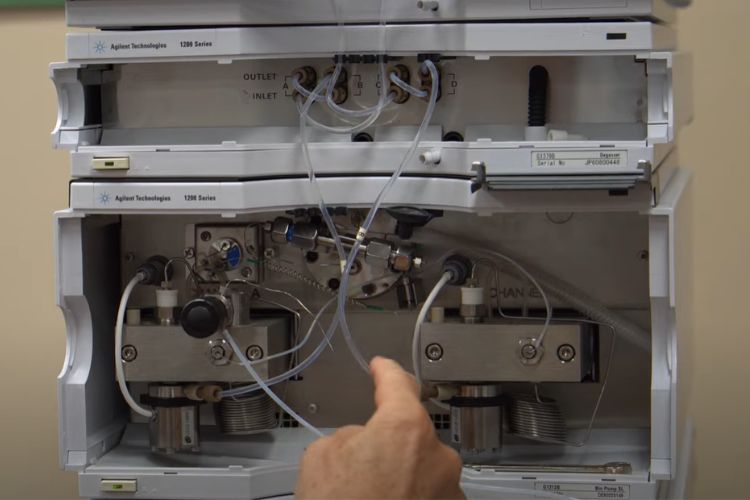

Method 1: Manual Purging – A Simple Flush

Most HPLC systems come equipped with a purge function on the pump. This method utilizes the pump itself to force air bubbles out of the system:

- Fill the mobile phase reservoir and ensure there are no visible bubbles.

- Open the purge valve, allowing solvent to flow freely to waste.

- Activate the purge function as per your instrument’s instructions. This will typically involve setting a higher flow rate for a short duration.

- Monitor the waste line for the appearance of bubbles. Continue purging until no more bubbles are observed.

- Close the purge valve and return to your desired flow rate.

Method 2: Column Backflushing – Reversing the Flow

This technique utilizes a reversed flow of solvent to dislodge air bubbles trapped within the column:

Important Note: Not all columns are compatible with backflushing. Consult your column manufacturer’s instructions before attempting this method.

- Stop the HPLC flow and ensure the column is equilibrated with the mobile phase.

- Set the flow direction to reverse using your instrument’s software or controls.

- Initiate a low flow rate backflush for a short duration (typically 1-2 minutes). This will gently push bubbles towards the inlet of the column.

- Switch the flow direction back to normal and continue with your analysis.

Method 3: Solvent Flushing – Leverage Viscosity

Certain high-viscosity solvents, like glycerol or polyethylene glycol (PEG), can be used to “sweep” out air bubbles:

- Prepare a solution of your chosen high-viscosity solvent in the mobile phase (typically 5-10% concentration).

- Purge the system using the method described earlier (Method 1).

- Run the high-viscosity solvent solution through the column at a low flow rate (around 0.1 mL/min).

- Switch back to your normal mobile phase and monitor for any remaining bubbles using the techniques mentioned in Section 3.

Method 4: Sonication – Ultrasonic Power

This method utilizes ultrasonic waves to dislodge trapped air bubbles:

Important Note: This technique should be used with caution, especially with delicate columns. Consult your column manufacturer’s instructions before proceeding.

- Partially fill an ultrasonic bath with solvent appropriate for your column.

- Submerge the column inlet tubing in the solvent bath, ensuring the column itself remains outside the bath.

- Activate the ultrasonic bath for a short duration (typically 2-3 minutes).

- Purge the system using the method described earlier (Method 1).

Method 5: Pressure Cycles – A Balancing Act

This technique applies alternating high and low pressure to “pop” trapped air bubbles:

- Set your instrument to run at a low flow rate.

- Manually increase the pressure to a slightly higher level than your typical operating pressure for a short duration (few seconds).

- Quickly decrease the pressure back to your normal operating pressure.

- Repeat this cycle a few times, allowing time for bubbles to dislodge between cycles.

- Monitor the pressure gauge for signs of stabilization, indicating the removal of bubbles.

Choosing the Right Weapon:

The most effective method for removing air bubbles depends on the severity of the problem, the type of column you’re using, and the available resources.

- For mild cases: Manual purging or solvent flushing are often sufficient.

- For stubborn bubbles or delicate columns: Sonication or pressure cycling might be considered with caution.

- Always consult your column manufacturer’s instructions to ensure compatibility with the chosen method.

By understanding these techniques and choosing the most appropriate one for your situation, you can effectively remove air bubbles and guarantee the smooth operation of your HPLC column, leading to reliable and accurate analytical results.

Aftercare and Prevention

Removing air bubbles is a victory, but the war isn’t over. Here’s how to ensure your HPLC system stays bubble-free and delivers optimal performance:

Post-Bubble Removal Measures:

- Run a blank solvent injection to confirm the absence of bubbles and system equilibration.

- Re-equilibrate the column with the mobile phase before proceeding with your samples.

Preventing Future Battles:

- Proper solvent degassing: Utilize a reliable degassing method like vacuum degassing to remove dissolved gases before running your analysis.

- Leak-free connections: Regularly inspect and tighten fittings to prevent air from entering the system.

- Fresh mobile phase: Use freshly prepared mobile phase whenever possible to minimize dissolved gas content.

- Reservoir level maintenance: Maintain an adequate solvent level in the reservoir to avoid cavitation in the pump.

Routine Maintenance is Key:

- Regular cleaning: Follow recommended cleaning procedures for your column and system to remove any accumulated contaminants that could trap air bubbles.

- Filter replacements: Replace solvent filters periodically to prevent particulate matter from entering the system and potentially creating nucleation sites for bubbles.

- System checks: Conduct routine performance checks to identify any potential issues that might contribute to air bubble formation.

Invest in Training:

- Ensure proper training for lab personnel on operating the HPLC system, including best practices for solvent preparation, bubble removal techniques, and preventive maintenance procedures.

By following these aftercare and preventative measures, you can significantly reduce the risk of air bubble formation and ensure the long-term health and performance of your HPLC system. Remember, a well-maintained HPLC system is a reliable partner in your analytical endeavors.