How HPLC System Works ?

A High-Performance Liquid Chromatography (HPLC) system works by separating and analyzing components in a sample. Here’s a simplified explanation of how it operates:

- The mobile phase (solvent) is stored in a reservoir.

- A pump delivers the mobile phase from the reservoir through tubing to an injector.

- The injector introduces the sample into the mobile phase stream, allowing it to mix.

- The mixture flows into a column packed with a stationary phase.

- As the mobile phase carries the sample through the column, different components interact with the stationary phase to varying degrees.

- Components that interact more strongly with the stationary phase will take longer to elute from the column, resulting in separation.

- The separated components exit the column and flow into a detector.

- The detector measures the concentration or properties of the separated components as they elute.

- The detector output is sent to a data system for analysis and interpretation.

- The data system generates a chromatogram, which is a graphical representation of the separated components over time.

- The chromatogram is used to identify and quantify the components in the sample.

The precise operation and parameters (e.g., flow rate, column type, detector wavelength) are optimized based on the specific analysis requirements. This process allows for the separation, detection, and quantification of components within a sample using an HPLC system.

How the HPLC system Works Based on these HPLC components ?

High-Performance Liquid Chromatography (HPLC) is a widely used technique for separating, identifying, and quantifying components in a mixture. Here’s a general overview of how an HPLC system works based on its components:

Solvent Filter : The mobile phase, which is typically a solvent or a mixture of solvents, is stored in the solvent reservoir. The solvent chosen depends on the nature of the sample and the separation requirements.

Pump: The pump delivers the mobile phase from the solvent reservoir to the rest of the system at a constant flow rate. The flow rate is carefully controlled to ensure reproducible and accurate results.

Injector: The injector introduces a small volume of the sample into the mobile phase stream. This can be done manually or using an autosampler for automated injections of multiple samples.

HPLC Column: The sample and mobile phase enter the column, which consists of a stationary phase packed into a cylindrical tube. The stationary phase is chosen based on its ability to selectively interact with the sample components.

Detector: As the mobile phase carries the sample through the column, the components separate based on their interaction with the stationary phase. The detector detects the separated components as they elute from the column.

Data System: The output from the detector is sent to a data system, which collects and processes the signals. The data system generates a chromatogram, which is a graphical representation of the detected signals over time. The chromatogram can be used for qualitative and quantitative analysis of the sample components.

Gradient Controller: In some cases, a gradient controller may be employed to vary the composition of the mobile phase over time. This allows for optimization of the separation by adjusting the solvent strength during the analysis.

Temperature Control System: Temperature control may be used to maintain a constant temperature throughout the system, as temperature variations can affect the separation and detection of components.

The combination of the pump, injector, column, detector, data system, and optional components like gradient controllers and temperature control systems work together to separate, detect, and analyze the components of a sample in an HPLC system. The specific parameters, such as flow rate, column type, and detector wavelength, are optimized based on the sample characteristics and the analytical objectives.

What you should to care when choose right HPLC components ?

When choosing the right HPLC components for your analysis, several factors should be taken into consideration:

Sample Compatibility: Consider the nature of your sample, including its solubility, chemical properties, and potential interactions with the stationary phase. Select components, such as the column and solvent, that are compatible with your sample to ensure accurate and reliable results.

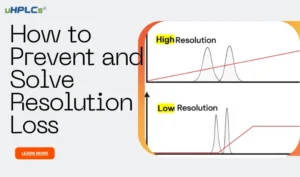

Separation Requirements: Determine the separation goals of your analysis, such as resolving specific compounds or achieving high-resolution separations. Choose components, such as the column and stationary phase, that provide the necessary selectivity and efficiency for your desired separation.

Analytical Requirements: Consider the sensitivity, detection limits, and specificity required for your analysis. Select a suitable detector that can effectively detect and quantify your analytes of interest. The choice of detector (UV-Vis, fluorescence, mass spectrometry, etc.) depends on the specific analytical needs.

Flow Rate and Pressure Considerations: Assess the flow rate requirements of your analysis, which can impact separation efficiency and analysis time. Ensure that the pump and tubing can handle the desired flow rate and associated system pressures without compromising performance or causing system failure.

System Compatibility: Ensure that the selected components are compatible with each other and can be integrated into a cohesive system. Consider factors such as tubing connections, fittings, and column dimensions to ensure seamless compatibility and efficient operation.

Budget and Cost: Evaluate the cost-effectiveness of the components, considering not only the initial purchase cost but also the maintenance and operational expenses. While it’s important to choose reliable and high-quality components, it’s also crucial to balance your budgetary constraints.

Manufacturer and Support: Consider the reputation, expertise, and customer support provided by the manufacturer of the HPLC components. Opting for reputable manufacturers can ensure reliable performance, availability of spare parts, and technical assistance when needed.

Future Expandability: Anticipate your future needs and potential expansions. Select components that offer flexibility for future upgrades, such as additional detectors, columns, or advanced modules, to accommodate evolving analytical requirements.

By carefully considering these factors, you can make informed decisions and choose the right HPLC components that meet your analytical needs, ensuring accurate, reliable, and efficient separations in your HPLC system.

Still have other important, but often overlooked components of HPLC instrument you should know ?

Certainly! While we have covered the fundamental components of an HPLC system, there are a few other important, yet sometimes overlooked, components worth mentioning:

Mobile Phase Degasser: A degasser removes dissolved gases from the mobile phase to ensure a consistent and bubble-free flow. It helps prevent pressure fluctuations, baseline noise, and potential issues with detector sensitivity and stability.

Check Valves: Check valves are crucial in maintaining the direction of the flow and preventing backflow in the HPLC system. They are typically located before and after the pump and injector to ensure unidirectional flow and prevent mixing of the mobile phase and sample.

Flow Cell: The flow cell is an integral part of the detector and serves as the point where the separated analytes pass and interact with the detector. It is important to ensure proper alignment, cleanliness, and optimal path length of the flow cell for accurate and sensitive detection.

Sample Filtration: Filtration of the sample before injection is essential to remove particulate matter and ensure the longevity and optimal performance of the column and other system components. It helps prevent blockages, pressure fluctuations, and column damage.

Column Oven: A column oven provides temperature control for the column during the separation process. It helps stabilize the column temperature, improving separation reproducibility and resolution, particularly for temperature-sensitive samples or when temperature gradients are used.

Pressure Relief Valve: A pressure relief valve protects the system from excessive pressure build-up, preventing damage to the column, pump, and other components. It acts as a safety measure and ensures the integrity and longevity of the system.

Waste Management System: Proper waste management is crucial for safe and efficient operation. A waste management system collects and safely disposes of the waste generated during the analysis, including used solvents and other hazardous materials.

Column Coupler: A column coupler or fitting connects the column to the rest of the system, ensuring a secure and leak-free connection. It is important to choose appropriate column couplers compatible with the column type and tubing dimensions.

These components, though sometimes overlooked, play important roles in maintaining the performance, reliability, and safety of an HPLC system. Taking them into consideration and ensuring their proper functioning can contribute to accurate and efficient separations.

If you have any questions about HPLC components, feel free to reach out to us at sales@uhplcs.com. Our team at uHPLCs is ready to assist you and provide the information you need. Contact us today!