High-performance liquid chromatography (HPLC) stands as a cornerstone in the world of analytical chemistry, providing unparalleled precision and efficiency in separating complex mixtures.

The heart of HPLC’s efficacy lies not just in the sophisticated machinery but significantly in the column packing, a seemingly minute yet crucial aspect that can dramatically sway the outcome of chromatographic analysis.

The common packing materials in liquid chromatography columns are C1, C3, C4, C8, C18, C30, amino, cyano, silica gel columns, etc.

Classification of packing materials in common chromatographic columns.

a. Reversed-phase (with ion-pair) method

C18 (octadecyl or ODS): good generality; strong retention and versatile

C8 (octyl): similar to C18, but slightly lower retention value

C3, C4: small retention value; mostly used for peptides and proteins

C1 [trimethylsilane (TMS)]: smallest retention value; most unstable

Phenyl, phenylethyl: moderate retention value; different selectivity

CN (cyano): moderate retention value; both normal and reversed phases can be used

NH2 (amino): weak retention; used for hydrocarbons; less stable

Polystyrene-based: stable in mobile phases with 1 < PH < 13; good for some separation peak shapes and long column life

b. Orthophase method

CN (cyano): good generality; moderate polarity; Versatile

OH (diol group): more polar than CN

NH2 (amino): more polar, less stable

Silica gel b: good universality; inexpensive; less convenient to operate; used to prepare LC

c. Space exclusion method

Silica gel b: excellent universal applicability; used as adsorbent

Silylated silica gel: weak adsorption, good solvent compatibility; for organic solvents

OH (diol-based): less stable; used in aqueous SEC (gel filtration)

Polystyrene-based b: widely used in organic SEC (gel permeation); generally incompatible with water and polar organic solvents

d. Ion exchange method

Bonded phase: poor stability and reproducibility

Impact of Packing Material on Separation Efficiency

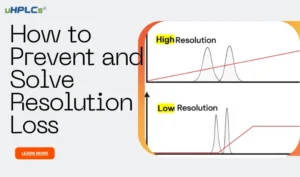

One critical aspect of column packing is the size of the packing particles. Smaller particles typically lead to better separation efficiency due to the increased surface area, but they also require higher pressure to maintain flow through the column.

Conversely, larger particles reduce the backpressure but may compromise the resolution. Pore size and surface area of the packing material further dictate the interaction between the analytes and the stationary phase, influencing the selectivity and efficiency of the separation process.

The Role of Packing Methodology in Column Lifespan

The method used to pack the column can significantly affect its lifespan and performance. Slurry packing, where the packing material is suspended in a solvent and then pushed into the column, is commonly used.

Dry packing is another method, though less prevalent. The choice between these methods depends on the type of analysis and the desired longevity of the column.

Effect of Packing on the Performance of HPLC Columns

1, the effect of particle size liquid chromatography column packing is that the smaller the average particle size, the smaller the vortex diffusion, the better the mass transfer, and the higher the column efficiency. However, the packing particle size is small, resulting in poor permeability performance and higher column pressure. At the same time, the wider the packing size distribution, the worse the permeation performance and the lower the column efficiency. The common packing particle size of 3μm, 3.5μm, 5μm, 10μm, etc.

2, the influence of the shape of liquid chromatography column packing is divided into amorphous and spherical. The amorphous packing preparation of the liquid chromatography column bed structure is not uniform, and the mobile phase linear velocity is not uniform. The chromatogram peak shape is wider; the spherical packing preparation of the liquid chromatography column bed structure is uniform, so the column efficiency is high and has good reproducibility. Spherical packing is the most common liquid chromatography column packing, and this packing has better performance and reproducibility.

3, the influence of bonded phase with silica gel as the matrix, through the chemical bonding of C18, C8, amino, cyano, and other groups bonded to the matrix, as the packing in the liquid chromatography column. By bonding different chemical groups, liquid chromatographic columns with different performances are obtained due to the different separation mechanisms of different bonding groups, affecting compounds’ retention and separation. The bonding of fillers makes the stationary phase of liquid chromatography columns relatively more stable and less susceptible to lose while largely eliminating the adverse effects of silicone hydroxyl groups, which can be applied in a wide range of mobile phases and widely used. However, the bonded filler is poor acid resistance, and the pH value can not be less than 2. When the mobile phase pH exceeds the acidic range, the bonded phase is easy to lose, and durability and stability will worsen.

4, the effect of end group sealing silica gel is widely used as a matrix material for liquid chromatography column packing because of its special surface chemical properties. The surface of silica gel has silicone hydroxyl groups, the density, distribution, and chemical properties of silicone hydroxyl groups will have different degrees of influence on the behavior of various types of chromatography. When silica-based HPLC columns, especially in reversed-phase columns, non-specific adsorption due to free silicone hydroxyl groups (or silanol groups) is often encountered. For some more polar solutes, such as alkalis, chromatographic summits can be severely trailed or even fail to elute due to strong adsorption. The effect of the silicone hydroxyl group is usually reduced by tailing the filler with a small silane (e.g., trimethylchlorosilane) to increase the surface coverage by reacting away some residual silicone hydroxyl group. This approach not only reduces irreversible adsorption or tailing but also increases the carbon content. However, this method does not completely react off the residual silicon hydroxyl groups, and 50% of the silicon hydroxyl groups are still left unreacted.

5, the effect of the carbon content of liquid chromatography column packing, especially the carbon content of reversed-phase packing, is often used to characterize the degree of surface chemical modification. Usually, carbon chains are introduced into the packing through bonding, and the higher the carbon content of the packing, the higher the density of carbon chains. The longer the carbon chains, the larger the capacity factor and the stronger the hydrophobicity. In reverse-phase conditions, the growth of carbon chains means that the filler has a larger specific surface area, the bonding is enhanced, and the retention of the material to be measured increases. Therefore, the liquid chromatography column with high carbon content packing has good stability and reproducibility, which is conducive to the separation of poorly retained compounds and can improve the trailing of polar compounds; the liquid chromatography column with low carbon content packing is conducive to the analysis of neutral and basic compounds and can reduce solvent loss.

6, the impact of other factors in addition to the above, the activity of silica gel packing, impurity content, pH stability, thermal stability, etc., will also affect the performance of the liquid chromatography column. When producing silica gel, the processing temperature and the silica gel activity are also different. The activity of silica gel is the main source of selectivity differences, mainly affecting the retention behavior of basic compounds; impurity content of silica gel is an important sign of the quality of the column, low content of heavy metals, silica hydroxyl activity is small, dragging the tail is reduced.

Troubleshooting Common Packing-Related Issues in HPLC Columns

A common issue in HPLC analysis is peak tailing, often attributed to improper column packing or the degradation of packing material.

By understanding the underlying causes, such as uneven packing or interactions between the packing material and analytes, chemists can implement strategies to mitigate these issues. Regular maintenance and proper packing techniques are key to prolonging column life and maintaining peak performance.

FAQs

What is the significance of particle size in HPLC column packing?

* The particle size in HPLC column packing affects the separation efficiency and pressure required to maintain flow. Smaller particles increase surface area for interaction, leading to better separation but higher backpressure.

How does the choice of packing material impact HPLC column performance?

* The choice of packing material influences the column’s selectivity, efficiency, and compatibility with different types of analytes. Different materials offer varying levels of interaction with the compounds being analyzed.

What are the common methods of packing an HPLC column?

* The two common methods are slurry packing and dry packing, each with its own advantages and suitability depending on the analysis requirements and desired column longevity.

How can packing-related issues like peak tailing be resolved?

* Resolving peak tailing involves checking for uniformity in packing, ensuring compatibility between packing material and analytes, and regular maintenance of the column.

What future trends can be expected in HPLC column packing?

* Future trends include the development of more advanced packing materials, smaller particle sizes for higher efficiency, and innovative packing methodologies to enhance column performance and lifespan.

Is the packing density of an HPLC column critical?

* Yes, the packing density is crucial for achieving optimal flow, resolution, and preventing band broadening, which affects the accuracy and precision of the chromatographic analysis.