Can’t Get Enough?

Get More Information and Quotation

for Our HPLC Column Hardware Today !

for Our HPLC Column Hardware Today !

Subscribe for exclusive offers and updates on new arrivals

Home » Comparative & Formulation Studies

The Partner You Can Trust for Comparative & Formulation Studies

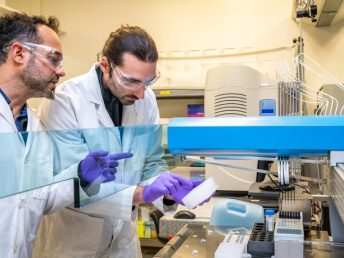

Advanced instrumentation for precise, multi-dimensional analysis.

Ensure your products meet FDA, CFDA, and EMA standards.

From reverse engineering to commercial-scale production.

Trusted by over 500 clients worldwide.

In today’s fast-moving markets, developing successful products isn’t easy.

Companies face multiple hurdles — from understanding competitors to ensuring compliance and scaling production.

We understand these challenges and provide solutions to overcome them.

| Your Challenge | Our Solution |

|---|---|

| ❌ Lack of insights into competitor products and market trends | ✅ Competitive Product Reverse Engineering |

| ❌ Difficulty developing stable and compliant formulations | ✅ Custom Formulation Development |

| ❌ Regulatory hurdles slowing down product launches | ✅ Regulatory Support & Guidance |

| ❌ Uncertainty in scaling lab formulations to commercial production | ✅ Process Optimization & Scale-Up Validation |

Comprehensive Solutions from Competitive Insights to Commercialization

We provide end-to-end solutions to help you analyze, develop, and optimize formulations across pharmaceuticals, cosmetics, food, and nutraceuticals.

Our services cover comparative studies, custom formulation development, and regulatory support, ensuring your products meet global standards and reach the market faster.

Comparative Studies – Competitive product reverse engineering, dissolution/performance comparison, and stability testing.

Formulation Development – Custom formulation design, process optimization, and scale-up validation.

Regulatory Support – Documentation and compliance guidance for FDA, CFDA, EMA, and other global agencies.

Commercialization Support – Seamless tech transfer and manufacturing readiness for market launch.

We begin by understanding your goals, sample requirements, and timelines.

A non-disclosure agreement (NDA) is signed to ensure confidentiality and regulatory compliance.

Define the scope of testing or development, key milestones, and project budget.

Align success criteria and deliverables before project kickoff.

Develop or transfer analytical methods and register samples.

Conduct risk assessment and experimental design using QbD (Quality by Design) and DoE (Design of Experiments).

Perform competitive product analysis, dissolution/performance testing, and stability studies.

Iterate formulation screening and small-scale trials for optimization.

Jointly review data and identify gaps.

Refine formulations and processes while preparing regulatory-ready data packages.

Transition from pilot to commercial scale with process qualification (IQ/OQ/PQ).

Develop SOPs, provide training, and support regulatory submission when required.

Deliver a comprehensive final report, raw data, and formulation/process documentation.

Provide continuous support for post-project needs or next-stage collaboration.

Comprehensive formulation research, comparative studies, and regulatory support to accelerate product development and ensure compliance.

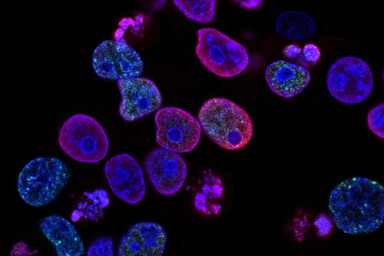

Identify actives, excipients, and process clues via LC-MS/GC-MS/NMR/XRPD; benchmark performance and map IP risks to reveal optimization paths.

Compare release/uptake, rheology, sensory or functional KPIs under matched conditions; establish equivalence/IVIVC to guide formulation decisions and filings.

ICH-guided accelerated/long-term studies across temp/RH & packaging; model shelf-life, failure modes, and mitigation for reliable market performance.

From concept to prototype: excipient screening, QbD/DoE design, critical attributes control, and built-in stability for pharma, cosmetics, food, and supplements.

Scale lab wins to plant: map CPPs/CMAs, raise yield & consistency, cut cycle time, and lock reproducibility for cost-effective production.

Regulatory-ready methods, CTD/PIF dossiers, validation protocols, and claims substantiation to accelerate compliant submissions and approvals.

Pilot-to-commercial tech transfer with IQ/OQ/PQ, SOPs, and training; de-risk launch with proven, auditable processes.

Industry & Background:

A fast-growing skincare brand needed to shorten product launch timelines while keeping up with global competition.

Challenge:

They lacked visibility into competitor formulations and struggled with stability issues for new active ingredients.

Solution:

We performed reverse engineering of benchmark competitor products, followed by custom formulation design using our QbD-based development process.

Result:

Product development cycle reduced by 40%

Stability issues decreased by 60%

3 new products launched successfully in 9 months

“Helped a cosmetic brand reduce product development cycle by 40% through reverse engineering and optimized formulation design.”

We strictly follow NDA (Non-Disclosure Agreement) protocols and have secure sample handling and data management systems.

All projects are fully confidential, and no information is shared without your written approval.

We work across pharmaceuticals, cosmetics & personal care, food & beverage, and nutraceuticals.

Our multi-technique lab and diverse expertise allow us to support companies from early-stage startups to global brands.

Turnaround times vary by project scope:

Competitive product reverse engineering: 2–4 weeks

Formulation development: 6–12 weeks

Regulatory documentation & validation: custom timelines based on requirements

We provide a clear project schedule during the proposal stage.

Yes. Our team is experienced with FDA, CFDA, EMA, and other international agencies.

We deliver regulatory-ready reports and can guide you through submission processes to ensure smooth approvals.

Yes, we support international sample shipments, following local import/export compliance rules.

We provide guidance on labeling, packaging, and documentation to ensure safe and efficient delivery.

Our lab is equipped with LC-MS, GC-MS, NMR, XRPD, ICP-MS, and other advanced instruments.

We follow ISO 17025 and GLP quality management systems, with strict calibration and validation protocols for every test.

Absolutely. We offer process optimization and scale-up validation services, including IQ/OQ/PQ, SOP creation, and staff training to ensure smooth transfer to manufacturing.

To create an accurate proposal, we typically need:

Project type (e.g., reverse engineering, formulation development)

Target industry and product category

Sample details and quantity

Desired timeline and regulatory requirements

Submit this information via our online inquiry form, and our team will respond within 1–2 business days.

Stay in touch with us to get latest news and special offers.

No. 43, Fukang Road, SHENZHEN, CN

+86 0755 28502380

sales@uhplcs.com

WhatsApp us

Subscribe for exclusive offers and updates on new arrivals