Can’t Get Enough?

Get More Information and Quotation

for Our HPLC Column Hardware Today !

for Our HPLC Column Hardware Today !

Subscribe for exclusive offers and updates on new arrivals

Home » Complex and Non-Routine Analytical Solutions

When standard tests fall short, you need a trusted partner with advanced capabilities, proven expertise, and strict confidentiality to solve your toughest analytical challenges.

LC-MS, GC-MS, NMR, ICP-MS, and advanced spectroscopy combined to solve the most complex problems.

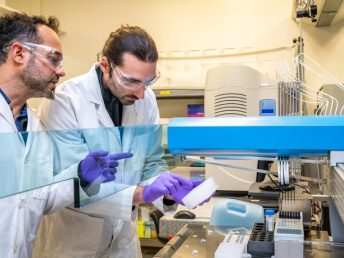

A cross-disciplinary team of scientists with decades of experience in complex and non-routine analysis.

NDA-backed processes aligned with ISO, GMP, and global regulatory standards to protect your sensitive data.

Agile project management to deliver actionable results within your critical timelines.

In today’s fast-paced industries, standard testing methods often fall short when faced with unique, complex, or high-risk projects.

Our laboratory specializes in solving non-routine analytical challenges, from unknown impurities to product failures, by delivering tailored, multi-technique solutions.

Whether you’re dealing with regulatory compliance, novel materials, or confidential IP-sensitive samples, we provide the expertise, technology, and confidentiality required to solve the toughest problems.

| Your Challenge | Our Solution |

|---|---|

| ❌ Unknown / Unexpected Impurities Unknown peaks or unexpected contaminants are discovered during testing, with no clear identification method. | ✅ Advanced Impurity Identification Use LC-MS, NMR, and multi-technique approaches to identify unknowns, confirm structures, and provide regulatory-ready reports. |

| ❌ No Existing Standard Method Your sample is novel or emerging, and there are no compendial or standard test methods available. | ✅ Custom Method Development Develop and validate tailored analytical methods specifically designed for your material or formulation. |

| ❌ Product Failure / Degradation Products degrade, fail, or lose stability during use or storage, causing costly delays or compliance issues. | ✅ Root Cause & Failure Analysis Determine degradation pathways, identify failure causes, and provide actionable solutions to prevent recurrence. |

| ❌ Complex Mixture / Multi-Component System Multi-component samples are too difficult to separate, identify, or quantify using routine tests. | ✅ Integrated Multi-Technique Testing Combine chromatography, spectroscopy, and advanced separation techniques to fully characterize complex mixtures. |

| ❌ Confidential / IP-Sensitive Projects Your sample or formulation contains highly sensitive intellectual property and requires strict confidentiality. | ✅ Secure & Compliant Processes NDA-backed workflows with ISO, GMP, and global regulatory compliance to ensure full protection of your proprietary information. |

Tailored analytical solutions to solve complex, non-routine challenges — from unknown impurities to method development and failure investigations.

Our laboratory specializes in non-routine analytical solutions for projects that go beyond standard testing. Whether you face unknown impurities, novel materials, product degradation, or multi-component mixtures, we design custom testing strategies using advanced technologies like LC-MS, GC-MS, NMR, and spectroscopy. With deep expertise, rigorous processes, and strict confidentiality, we help you achieve clarity, compliance, and confidence in every result.

Our streamlined workflow ensures confidentiality, precision, and timely results for every non-routine analytical project.

We understand your project goals, sample background, and requirements, while signing an NDA to protect your intellectual property.

Our team evaluates your challenge, selects the right analytical techniques, and outlines a clear testing scope.

You receive a customized work plan, detailed quotation, and clear project milestones for alignment.

Secure handling and documentation of your samples with full traceability and chain of custody.

Multi-technique testing using LC-MS, NMR, ICP-MS, spectroscopy, and other advanced instruments.

Delivery of a regulatory-ready report, followed by a consultation to explain results and next steps.

Comprehensive formulation research, comparative studies, and regulatory support to accelerate product development and ensure compliance.

Identify and characterize unknown peaks, impurities, and contaminants using LC-MS, NMR, and advanced techniques.

Detect and study degradation pathways to ensure product stability and compliance.

Separate, identify, and quantify multi-component or highly complex formulations.

Design and validate non-routine analytical methods tailored to your specific needs.

Develop and optimize methods beyond pharmacopeial standards for emerging or novel products.

Transfer validated methods to your in-house team and support regulatory submissions.

Investigate product performance failures and identify degradation or contamination causes.

Compare formulations, competitors, or prototypes for R&D or regulatory purposes.

NDA-backed workflows with strict ISO/GMP compliance to protect proprietary data.

Industry & Background:

Discover how our non-routine analytical solutions have helped clients across industries solve complex challenges — from unknown impurity identification to custom method development and product failure investigations.

These real-world cases showcase our multi-technique approach, regulatory compliance, and proven results.

| Industry | Challenge | Our Solution | Result |

|---|---|---|---|

| Pharmaceutical | A new drug batch showed unknown peaks during HPLC testing, risking regulatory approval. | Applied LC-MS + NMR to identify the unknown impurity and its degradation pathway, developed a custom non-compendial method for ongoing QC. | Client gained regulatory-ready data within 3 weeks, avoiding costly production delays. |

| Material Science | A specialty polymer experienced unexplained product failures in field use, causing warranty claims. | Used multi-technique surface and structural analysis (FTIR, SEM, GC-MS) to determine chemical incompatibility with additives. | Identified root cause and provided actionable material change recommendations, reducing failures by 85%. |

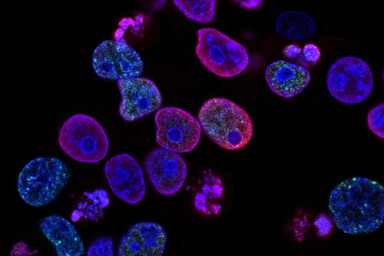

| Biotech | Complex protein mixture could not be separated or characterized with routine methods. | Designed a custom separation workflow with advanced LC-MS/MS and spectroscopy. | Delivered full characterization of all protein components, supporting patent submission and FDA filing. |

Non-routine analytical testing refers to customized, high-complexity laboratory analysis designed for projects that cannot be addressed by standard or pharmacopeial methods.

It is typically required when:

Your product is new or highly specialized, with no existing test methods.

You encounter unknown impurities, unexpected peaks, or unexplained performance failures.

Routine QC testing fails to provide actionable answers.

Regulatory authorities request non-compendial or investigational data for compliance.

By combining advanced techniques such as LC-MS, GC-MS, NMR, ICP-MS, spectroscopy, and multi-disciplinary expertise, non-routine testing delivers tailored, scientifically defensible results that support R&D, quality control, and regulatory submissions.

We understand that many of our clients work with proprietary formulations, novel compounds, or sensitive intellectual property (IP). Protecting your confidentiality is our highest priority:

NDA (Non-Disclosure Agreement): Signed before any discussion or sample transfer.

Secure Sample Chain of Custody: All samples are logged, barcoded, and stored in controlled-access facilities.

Data Security: Analytical data is stored on encrypted servers with restricted access.

ISO & GMP Compliance: Our processes meet international regulatory standards, ensuring both confidentiality and traceability.

This rigorous framework allows you to collaborate with confidence, knowing that your innovation is fully protected.

Our Complex & Non-Routine Analytical Solutions support a wide range of industries where precision and compliance are critical:

Pharmaceuticals & Biotech: Drug impurity profiling, degradation product studies, protein characterization.

Medical Devices: Material analysis, extractable and leachable studies.

Specialty Chemicals & Polymers: Root cause analysis of product failures, formulation development.

Electronics & Semiconductors: Contamination identification, high-purity material verification.

Food & Beverage: Complex natural product characterization, safety verification.

Environmental & Industrial: Trace contaminant detection, compliance testing.

Our multi-technology platform and cross-disciplinary team allow us to adapt to both regulated and non-regulated industries.

Turnaround time depends on sample complexity, method development needs, and regulatory requirements:

Simple Investigations: 5–7 business days once samples are received.

Moderate Complexity Projects: 2–3 weeks, including preliminary data review.

Custom Method Development: 3–6 weeks, depending on validation scope and reporting needs.

We always provide a clear timeline in our proposal phase, with milestones for progress updates.

Urgent projects may qualify for expedited analysis, depending on instrument availability and sample readiness.

When no standard method exists, our team specializes in custom method development:

Feasibility Assessment: Evaluate the material, matrix, and regulatory context.

Design Phase: Select appropriate technologies (e.g., LC-MS, GC-MS, spectroscopy).

Pilot Testing: Run initial tests to optimize method parameters.

Validation: Confirm method performance (specificity, sensitivity, accuracy, precision).

Documentation: Deliver a regulatory-ready method package for future use.

This process ensures your unique materials are analyzed accurately and that the data will be accepted by regulatory bodies worldwide.

Absolutely. Our reporting process follows global regulatory guidelines, ensuring acceptance by agencies such as FDA (U.S.), EMA (Europe), and ICH:

GLP/GMP-Compliant Documentation: Full traceability and audit-ready formatting.

Clear Data Presentation: Chromatograms, spectra, and detailed interpretation.

Non-Compendial Method Justification: When required for novel products.

Certificate of Analysis (CoA): Provided upon request.

This level of documentation helps our clients streamline approval processes, reduce audit risks, and meet the highest industry standards.

Pricing for non-routine analytical testing is based on several factors:

Complexity of Analysis: Number of techniques required and sample preparation difficulty.

Scope of Work: Whether it’s a one-time investigation or ongoing monitoring program.

Regulatory Requirements: Additional validation and reporting steps for compliance.

Turnaround Time: Expedited projects may incur rush fees.

We provide transparent, itemized quotations before any work begins, ensuring no surprises.

For long-term clients or high-volume projects, custom pricing packages and annual agreements are available.

Getting started is simple and secure:

Initial Consultation: Share a brief description of your challenge via our online form or email (NDA signed before sharing sensitive details).

Feasibility Review: Our scientists assess your requirements and suggest an analytical path.

Proposal & Quotation: You receive a detailed plan, timeline, and cost estimate.

Sample Submission: Secure chain of custody and logged tracking.

Analysis & Reporting: Execution of the plan with progress updates.

Final Consultation: We review results with you and provide recommendations for next steps.

This step-by-step process ensures clarity, confidentiality, and high-quality results every time.

Stay in touch with us to get latest news and special offers.

No. 43, Fukang Road, SHENZHEN, CN

+86 0755 28502380

sales@uhplcs.com

WhatsApp us

Subscribe for exclusive offers and updates on new arrivals