Introduction

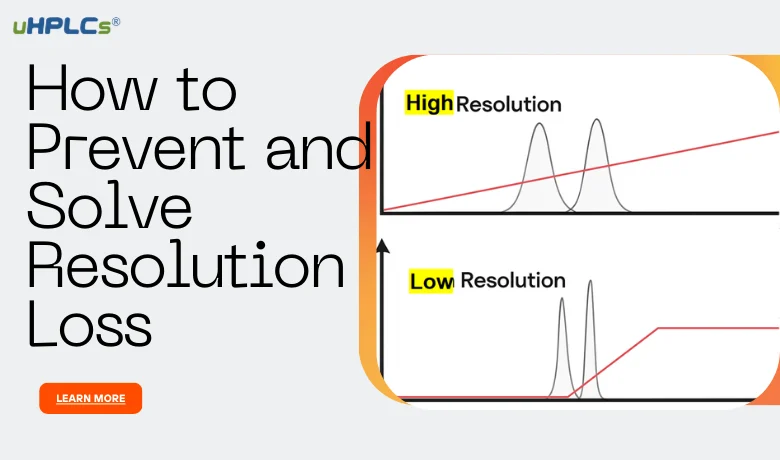

In High-Performance Liquid Chromatography (HPLC), resolution is a key factor that determines the ability to separate and identify analytes accurately. When resolution decreases, peaks begin to overlap, quantification becomes unreliable, and valuable research time is wasted on troubleshooting. This issue is common in both research and quality control laboratories, and it can arise from multiple sources including the column, mobile phase, instrument setup, or even the sample itself.

This article explores the most frequent causes of reduced HPLC resolution and provides practical solutions—along with tools and accessories that can help prevent and resolve these problems effectively.

Common Causes of Resolution Loss in HPLC

Resolution loss in High-Performance Liquid Chromatography (HPLC) can originate from a variety of sources, including the column, mobile phase, instrument configuration, and sample properties. Identifying the underlying cause is essential to restoring separation efficiency and ensuring reliable analytical results.

1. Column-Related Issues

·Column aging and degradation: Over time, the stationary phase loses efficiency, leading to reduced separation capacity.

·Packing material damage: Settling, compression, or the formation of voids within the column bed disrupts uniform flow paths.

·Contamination: Strongly retained analytes, particulates, or matrix residues accumulate at the column head, reducing efficiency.

·Improper column choice or misuse: Using an unsuitable stationary phase or operating outside recommended temperature and pressure limits further compromises resolution.

2. Mobile Phase Problems

·Incorrect solvent composition: Inaccurate solvent ratios or unstable gradients can alter retention and peak separation.

·pH fluctuations or buffer instability: Small pH changes or buffer precipitation may disturb analyte–stationary phase interactions.

·Poor solvent quality: Contaminated or degraded solvents increase baseline noise and reduce reproducibility.

·Inadequate degassing: Dissolved gases may lead to baseline drift, ghost peaks, and inconsistent resolution.

3. Instrumental Factors

·Pump issues: Pulsation or pressure instability distorts flow and impacts peak shape.

·Injector problems: Leakage or poor sample introduction reduces reproducibility.

·Detector misalignment: Signal instability or poor calibration decreases accuracy of separation.

·Dead volume: Improper connectors or oversized tubing increase band broadening and decrease resolution.

4. Sample-Related Factors

·Overloading: Injecting highly concentrated samples causes peak tailing or fronting.

·Insoluble particulates: Undissolved matter blocks flow paths and damages column performance.

·Sample degradation: Unstable compounds may decompose during analysis, generating unexpected peaks.

·Complex sample matrices: High background interferences increase co-elution and reduce effective separation.

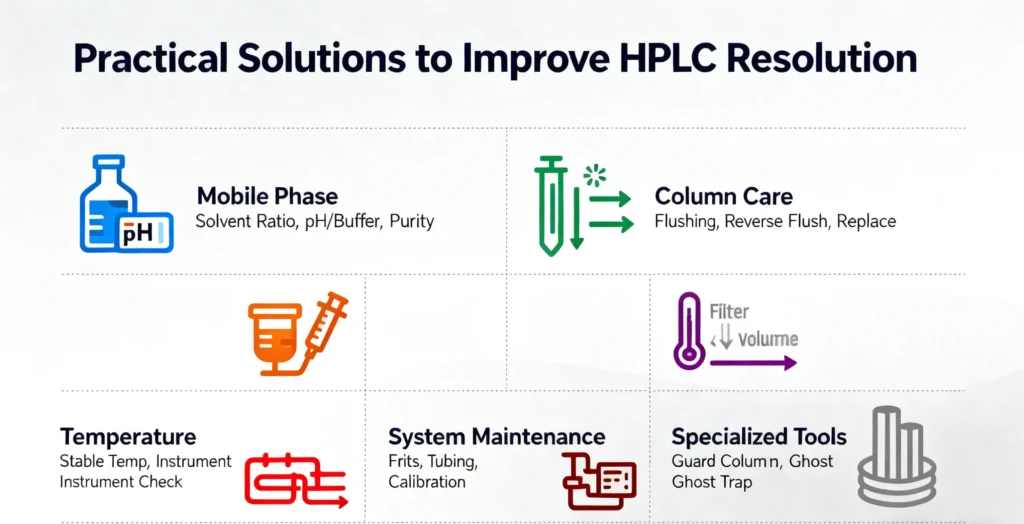

Practical Solutions to Improve Resolution

When resolution decreases in HPLC, the problem can often be resolved through targeted interventions. Below is a comprehensive set of solutions, organized by category:

1. Mobile Phase Optimization

·Adjust Solvent Strength and Composition: Modify the ratio of aqueous to organic phase to achieve better selectivity. Increasing organic content generally reduces retention, while decreasing it may improve separation.

·Fine-Tune pH and Buffer Concentration: For ionizable compounds, small pH adjustments can significantly impact selectivity. Ensure buffer concentration is sufficient to maintain stable pH during separation.

·Use High-Purity Solvents: Low-quality solvents can introduce impurities that cause baseline drift or ghost peaks, reducing resolution.

2. Column Care and Maintenance

·Regular Column Flushing: Wash the column with strong solvents compatible with the stationary phase (e.g., methanol, acetonitrile, or water) to remove retained contaminants.

·Reverse Flushing: Occasionally flush the column in reverse to dislodge particulates trapped at the inlet.

·Replace Worn Columns: If peak efficiency cannot be recovered after cleaning, the column may have reached the end of its usable life.

3. Sample Preparation and Injection Control

·Filter Samples Before Injection: Use 0.22 µm or 0.45 µm filters to remove particulates that could clog frits and broaden peaks.

·Reduce Injection Volume: Overloading the column with too much sample volume or concentration can cause band broadening.

·Dilute Highly Concentrated Samples: Lower concentrations help maintain sharp, well-resolved peaks.

4. Temperature and System Stability

·Maintain Consistent Column Temperature: Fluctuating temperatures affect retention times and selectivity. A column oven ensures stable conditions.

·Monitor Instrument Stability: Inspect pump seals, autosampler syringes, and degassers to prevent variability in flow or mixing.

5. System Maintenance and Hardware

·Replace Clogged Frits and Inline Filters: Blockages can cause high backpressure and peak distortion.

·Inspect Tubing and Connections: Damaged or misaligned fittings can lead to dead volumes, which reduce resolution.

·Calibrate Detector and Pump Performance: Regular calibration ensures accurate signal detection and stable flow rates.

6. Specialized Tools for Persistent Issues

·Use Guard Columns: Protect the main column from strongly retained contaminants and extend its lifespan.

·Install a Ghost Peak Trap Column: The uHPLCs Ghost Peak Trap Column, placed between the mixer and degasser, removes hidden impurities and fine particles before they reach the analytical column. This reduces ghost peaks, improves baseline stability, and ensures cleaner separations.

Case Study: Improving Resolution in Pharmaceutical Impurity Analysis

In pharmaceutical quality control, accurate impurity profiling is critical to ensure both safety and regulatory compliance. However, analysts often face a situation where two closely related impurities co-elute, leading to poor resolution and unreliable quantification.

In one case, a laboratory observed a significant drop in resolution when analyzing an active pharmaceutical ingredient (API) with gradient elution. Despite using a high-quality reversed-phase column, the chromatograms showed overlapping peaks and baseline disturbances.

Upon investigation, several contributing factors were identified:

*Column contamination from repeated injections of complex sample matrices.

*Buffer precipitation caused by improper mobile phase preparation.

*Ghost peaks introduced by hidden impurities in the system.

To address the issue, the lab implemented a systematic approach:

*The column was regenerated using appropriate flushing protocols.

*A Ghost Peak Trap Column was installed between the mixer and degasser to remove hidden contaminants before reaching the analytical column.

*An inline filter was added to protect the system from particle contamination.

After these steps, peak separation improved significantly, baseline stability was restored, and the resolution between critical impurity peaks exceeded acceptable system suitability criteria. The solution not only recovered the analytical performance but also reduced downtime and improved reproducibility for future runs.

This example highlights how a combination of proper troubleshooting and the right consumables can restore—and even enhance—chromatographic performance.

Conclusion

Resolution loss in HPLC is a common yet solvable problem. By identifying its causes—such as column aging, inappropriate mobile phase, or system contamination—researchers can apply the right corrective actions. Preventive practices like regular system care, optimized method parameters, and effective sample preparation remain critical to maintaining stable separation.

For more reliable performance, laboratories can benefit from uHPLCs high-resolution HPLC columns, designed to deliver sharper peaks and superior separation. In addition, protective tools like the Ghost Peak Trap Column (for removing hidden impurities) and inline filters (for preventing particle contamination) help extend column life and improve data consistency. Contact us at sales@uhplcs.com to learn more.

With the right troubleshooting strategies, combined with the use of precision-engineered columns and accessories, researchers can achieve cleaner signals, reproducible results, and long-term confidence in their HPLC workflows.