How to Select an HPLC Column from Four Key Dimensions

Introduction Ever struggled to decide which HPLC column to use for your analysis? You’re not

Home » HPLC Application for Nitrosamine Impurities

Contact uHPLCs Today for Any Questions for HPLC / UHPLC

Introduction Ever struggled to decide which HPLC column to use for your analysis? You’re not

Introduction Ever wondered how scientists ensure your medicine is pure, or your drinking water is

Introduction Food safety is a critical priority for both manufacturers and regulators. Beyond protecting public

High-Performance Liquid Chromatography (HPLC) is a valuable tool in identifying and quantifying nitrosamine impurities in pharmaceuticals. Nitrosamines are a class of compounds known to be potentially carcinogenic, making their detection crucial for ensuring drug safety.

HPLC, often combined with mass spectrometry (LC-MS), provides a reliable and sensitive method for nitrosamine detection. It allows separation and quantification of nitrosamines even at very low levels, ensuring adherence to regulatory limits.

HPLC’s applications include routine quality control testing, stability studies, and investigations into the presence of nitrosamines in drug substances, intermediates, and final products. As such, it plays a vital role in protecting public health by ensuring the purity and safety of pharmaceutical products.

High-Performance Liquid Chromatography (HPLC) is extensively employed in various industries, including pharmaceuticals, food, and environmental sciences, for detecting and quantifying nitrosamine impurities. Nitrosamines, classified as potential carcinogens, can pose significant health risks, necessitating their identification and control in numerous industrial processes and products.

1.) In the pharmaceutical industry, HPLC, especially when used in combination with mass spectrometry (LC-MS), plays a crucial role in ensuring the safety and quality of drug products by detecting nitrosamines at extremely low levels. This is vital for complying with the strict regulatory standards that mandate limits on nitrosamine content in pharmaceuticals.

2.) In the food industry, HPLC is used to identify nitrosamine impurities in food products, especially processed meats, beer, and cheese, where nitrosamines can form during manufacturing or storage.

3.) In the environmental sector, HPLC is used to detect nitrosamines in water and soil samples, contributing to the surveillance of environmental pollutants and aiding in risk assessment and mitigation strategies.

By facilitating the identification, quantification, and control of nitrosamine impurities, HPLC plays an essential role in ensuring product safety and quality, protecting public health, and maintaining regulatory compliance across numerous industries.

The detection and quantification of nitrosamine impurities in various industries, particularly pharmaceuticals and food, requires the optimal operation of High-Performance Liquid Chromatography (HPLC) systems. The use of high-quality HPLC consumables is critical to this process. Here’s what you should care about if you’re in an industry dealing with nitrosamine impurities:

Columns: HPLC columns play a crucial role in separating nitrosamines from other compounds. The right choice of column depends on the specific nitrosamines you’re analyzing, and it’s important to ensure the column is in good condition to get reliable results.

Mobile Phase Solvents: The purity of the solvents used is critical for accurate detection of nitrosamines, as impurities in solvents can interfere with the detection.

Filters and Frits: These are important for maintaining the overall integrity of the system and preventing clogging of the column. Regular replacement is necessary to ensure efficient operation.

Tubing and Connectors: High-quality, durable tubing and connectors are necessary to withstand the high pressures within the HPLC system, maintain consistent flow rates, and prevent leaks that could compromise the analysis.

Duis condimentum nunc metus, maximus porta velit temporin. Intincidunt leo viverra, sodales ex eu, posuere purus. Duis in augue vestibulum, aliquet nulla vitae, tempus tellus.

HPLC consumables are crucial components that significantly influence the overall effectiveness, accuracy, and reliability of HPLC analysis. Given the potential carcinogenic nature of nitrosamines and the stringent regulatory limits on their presence, ensuring the optimal operation of the HPLC system with high-quality consumables is paramount. These consumables include columns, mobile phase solvents, filters, frits, tubing, connectors, and vials, each of which plays a vital role in achieving accurate and reliable results.

The HPLC column plays a significant role in separating nitrosamines from other compounds. When it comes to replacing it, consider the type of column needed for your specific analysis. This involves the stationary phase, size, and particle size. Additionally, ensure the column is replaced when there are signs of performance decline, such as decreased resolution or increased backpressure. Always follow the manufacturer’s instructions for column installation to prevent any damage or incorrect installation.

The frequency of replacement depends on the usage and storage conditions. However, maintaining high purity is crucial for accurate nitrosamine detection. Therefore, mobile phase solvents should be replaced regularly and stored as per the manufacturer’s instructions to prevent contamination. Always ensure to use high-purity solvents specifically designed for HPLC to maintain peak performance.

Filters and frits should be replaced regularly to prevent system blockages. Before replacing, ensure that you have the correct type of filter or frit for your system. Always handle them with care to prevent any damage. Once replaced, monitor the system pressure to confirm the replacement was successful and that there are no blockages.

Proper training, regular maintenance schedules, and adherence to manufacturer’s instructions are essential. Everyone involved in the HPLC analysis should be adequately trained on how to replace and maintain the HPLC consumables properly. Establish a regular maintenance schedule to check the condition of consumables and replace them as needed. Also, always follow the manufacturer’s instructions for replacing consumables to ensure they are installed correctly and the system’s performance is not compromised.

The proper replacement of HPLC consumables is crucial for maintaining the accuracy and reliability of nitrosamine impurity analysis. Using fresh, high-quality consumables ensures the integrity of the analysis. Worn-out or low-quality consumables can lead to inaccurate results, poor reproducibility, and increased downtime due to system failures. Therefore, regular and proper replacement of HPLC consumables is vital for maintaining the high standards required for nitrosamine impurity analysis.

Absolutely, the choice of HPLC consumables can significantly influence the detection and quantification of nitrosamine impurities. For instance, the selection of HPLC columns depends on the specific nitrosamines being analyzed – their chemical properties will determine the type of column and stationary phase required for optimal separation. The purity of the mobile phase solvents is also crucial, as impurities can interfere with the detection of nitrosamines. The quality and cleanliness of vials, caps, and filters can influence the accuracy and reliability of the analysis by preventing contamination. Therefore, the choice and management of HPLC consumables are critical factors in nitrosamine impurity analysis.

Delaying the replacement of HPLC consumables can compromise the accuracy and precision of nitrosamine impurity analysis. Worn-out or degraded consumables can lead to issues such as increased system backpressure, poor peak shapes, inconsistent retention times, and potential sample contamination – all of which can adversely affect the results. Moreover, neglecting the timely replacement of consumables could potentially damage the HPLC system, leading to expensive repairs or even system failure.

Proper storage of HPLC consumables is essential to maintain their effectiveness. Columns should be stored as per the manufacturer’s recommendations, usually in a sealed container at room temperature. Mobile phase solvents should be kept in a cool, dark place and tightly sealed to prevent contamination or evaporation. Filters, frits, and tubing should be kept in a clean, dust-free environment. Vials and caps should also be stored in clean containers to prevent any contamination that could interfere with nitrosamine impurity analysis.

Yes, there are several training programs offered by HPLC system and consumable manufacturers, as well as independent training institutions, that provide detailed instructions on the handling and replacement of HPLC consumables. These programs often cover topics such as system operation, routine maintenance, troubleshooting common problems, and specific applications like nitrosamine impurity analysis. It’s crucial that all personnel involved in the operation of the HPLC system are adequately trained to ensure accurate and reliable nitrosamine impurity analysis.

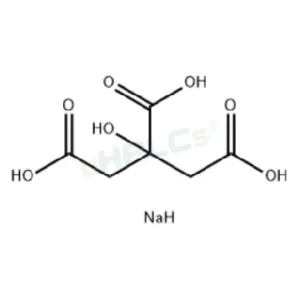

Uridine 5’-triphosphate Trisodium Salt (UTP-Na₃) Reference Standard | CAS 19817-92-6 | High-Purity Reference Materiel Product Code: U-D25015X Chemical Name: Uridine 5’-triphosphate Trisodium Salt (UTP-Na₃) Category:

Glutathione (G-SH) Reference Standard | CAS 70-18-8 | High-Purity Reference Materiel Product Code: G-D25016X Chemical Name: Glutathione (G-SH) Category: Drug Impurity Standard CAS Number: 70-18-8

Adenosine 5’-triphosphate Disodium Salt Reference Standard | CAS 987-65-5 | High-Purity Reference Materiel Product Code: A-D25014X Chemical Name: Adenosine 5’-triphosphate Disodium Salt Category: Drug Impurity

WhatsApp us

Subscribe for exclusive offers and updates on new arrivals