Short Answer:

In most cases, installing an HPLC column upside down won’t cause major problems.

HPLC columns are designed to be symmetrical, and the flow direction generally doesn’t affect their performance.

Power of HPLC: Separation with Precision

High-performance liquid chromatography (HPLC), also known as high-pressure liquid chromatography, is a cornerstone technique in analytical chemistry. It excels at separating, identifying, and quantifying the individual components within a complex mixture. Imagine a toolbox filled with various tools, all mixed together. HPLC acts like a magic sorting machine, meticulously separating each tool based on its unique characteristics.

HPLC’s significance in analytical chemistry is undeniable. Here’s why:

- Unveiling the Hidden: Many essential compounds, like drugs, vitamins, and pollutants, are often found in complex mixtures. HPLC allows us to isolate and analyze each component individually, providing valuable insights into their presence and quantity.

- Purity Matters: In the pharmaceutical industry, ensuring the purity of drugs is critical. HPLC helps guarantee the absence of unwanted contaminants by separating the active ingredient from any impurities present.

- A Forensic Fingerprint: From environmental monitoring to forensic analysis, HPLC plays a crucial role. It can identify and quantify specific compounds in a sample, aiding investigations and environmental assessments.

Understanding HPLC Column Installation

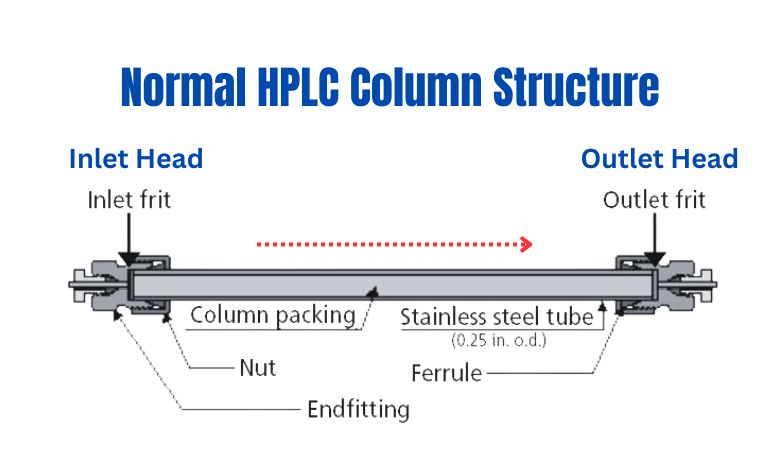

The HPLC column is the workhorse of the system, where the magic of separation happens. It’s a slender, high-pressure resistant tube packed with a stationary phase, typically microscopic particles. Here’s a breakdown of its key components:

- Stainless Steel Tube: This robust tube houses the stationary phase and withstands the high pressures used in HPLC.

- Stationary Phase: The heart of the separation process. These microscopic particles interact with the sample components at varying degrees, leading to their separation.

- Frit: A porous disk located at each end of the column. It prevents the stationary phase particles from escaping while allowing the mobile phase (solvent) to flow through.

- Fittings: These specialized connectors allow the column to be securely attached to the HPLC system’s tubing.

Installing for Success: The Standard Procedure

Installing an HPLC column requires meticulous attention to detail. Here’s a general outline of the standard procedure:

- Preparation: Consult the manufacturer’s instructions for specific details. Always wear gloves and safety glasses when handling the column.

- Inspection: Carefully examine the column for any damage or leaks. Ensure the flow direction is properly marked (usually with an arrow).

- Frits and Fittings: Inspect the frits for integrity and ensure the fittings are clean and free of debris.

- Connecting the Column: Using appropriate wrenches, attach the column to the HPLC system’s tubing. Finger-tighten initially, followed by careful tightening with the wrenches according to the manufacturer’s recommendations.

- Flow Path Check: Ensure all connections are secure before turning on the pump. Start with a low flow rate and gradually increase it to the desired operating pressure. Monitor for any leaks.

- Column Conditioning: Depending on the column type and mobile phase, a conditioning step might be necessary to ensure optimal performance.

Common Mistakes and the Upside-Down Blunder

While seemingly simple, column installation can suffer from a few common errors:

- Overtightening: Excessive force on the fittings can damage the column or cause leaks.

- Improper Frits: Damaged or improperly seated frits can lead to loss of stationary phase or uneven flow.

- The Upside-Down Debacle: This, although not catastrophic, can potentially affect performance. As discussed earlier, reversing the flow might disturb the packing or worsen existing weaknesses.

While an upside-down column might not cause immediate issues, it’s generally not recommended. Following proper installation procedures ensures optimal performance, protects your expensive column, and allows you to reap the full benefits of HPLC’s analytical power.

Consequences of Upside Down Installation

In most cases, installing an HPLC column upside down won’t cause dramatic changes in performance immediately. That’s because HPLC columns are designed to be symmetrical, and the flow direction generally doesn’t significantly impact separation mechanisms.

However, there are some subtle immediate effects to consider:

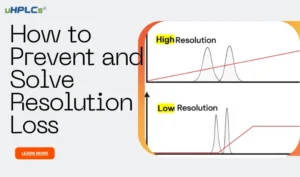

- Peak Broadening: Over time, the stationary phase in an HPLC column can settle slightly. Reversing the flow might disturb this settled packing, leading to a slight broadening of chromatographic peaks. Broadened peaks can make it harder to distinguish between closely eluting components.

- Increased Backpressure: If the packing is disturbed by reversed flow, it can create a minor increase in backpressure. Backpressure is the resistance the mobile phase experiences as it flows through the column. Increased backpressure can decrease chromatographic efficiency.

Potential Damage to the Column

While the immediate effects on performance might be subtle, there’s a potential for damage to the column structure and stationary phase when installed upside down:

- Exacerbating Weaknesses: If the column has any pre-existing weaknesses or voids in the packing, reversing the flow could worsen these issues. This could lead to channeling (uneven flow paths) or even cracking of the frit (the porous disk at the end of the column).

- Packing Disruption: As mentioned earlier, reversed flow can disrupt the settled packing material. In severe cases, this might permanently alter the column’s chromatographic properties, affecting future separations.

Impact on Analytical Results

The impact of an upside-down column on analytical results depends on the severity of the effects mentioned above:

- Minor Peak Broadening: If the peak broadening is minimal, it might not significantly affect the ability to identify and quantify components. However, reduced resolution could make it challenging to separate closely eluting peaks.

- Increased Backpressure: A minor increase in backpressure typically wouldn’t drastically alter results. However, very high backpressure can affect peak shapes and retention times, impacting the accuracy of quantification.

- Packing Damage: If the reversed flow causes severe packing disruption or frit damage, the column’s performance can be significantly compromised. This could lead to distorted peaks, inaccurate retention times, and unreliable quantification.

In conclusion, while an upside-down column might not cause immediate issues, it increases the risk of performance degradation and potential damage. To ensure reliable and accurate analytical results, always follow proper installation procedures.

Diagnosing an Incorrect Installation

Unfortunately, there’s no single definitive test to diagnose an upside-down column installation with absolute certainty. However, several signs and diagnostic tests can raise suspicion and guide further investigation:

Signs of a Potential Issue:

- Changes in Peak Shape: A subtle increase in peak broadening might indicate a disturbed packing bed due to reversed flow. However, peak broadening can have other causes as well.

- Increased Backpressure: A minor increase in backpressure compared to historical data for the same column and mobile phase could be a clue, but further confirmation is needed.

- Retention Time Shifts: If retention times for known standards consistently deviate from established values, it could suggest an issue with the column, including potentially reversed flow.

Diagnostic Tests:

- System Suitability Test: Running a system suitability test with a standard mixture can reveal changes in peak resolution, asymmetry, or plate number. While not specific to flow direction, these deviations can point towards potential column problems.

- Comparison with Reference Column: If available, comparing the performance of the suspect column with a correctly installed reference column using the same mobile phase and sample can be helpful. Deviations in peak shapes or retention times between the two can strengthen the case for an upside-down installation.

- Flow Direction Verification: This might seem obvious, but carefully consult the manufacturer’s instructions and the column itself for any directional markings (usually an arrow). If the column is accessible, visually confirm the flow direction through the frit.

Important Considerations:

- These signs and tests are not conclusive. Other factors can also cause similar effects.

- Consistency is key. If the observed changes are sporadic or inconsistent, an upside-down column might be less likely the culprit.

Recommendations:

- If you suspect an upside-down column, consult the manufacturer’s recommendations. They might suggest additional diagnostic tests or cleaning procedures.

- In many cases, the potential risks associated with an upside-down column (even if the immediate effects seem minor) outweigh the benefits. Consider reinstalling the column correctly to ensure optimal performance and reliable results.

Corrective Actions You Should Do

A Guide to Correct Column Re-installation

If you suspect an upside-down column installation, here’s a step-by-step guide to reinstall it correctly :

Preparation:

- Safety First: Always wear gloves and safety glasses when handling the column.

- Consult the Manual: Refer to the manufacturer’s instructions for specific details regarding your column and HPLC system.

- Gather Tools: Assemble the necessary wrenches or tools for column fittings.

- Power Down: Turn off the HPLC pump and ensure the system is depressurized.

Re-installation Steps:

- Disconnect the Column: Using the appropriate wrenches, carefully loosen and disconnect the column from the HPLC system’s tubing.

- Visual Inspection: Inspect the column for any signs of damage. Ensure the flow direction markings (usually an arrow) are visible.

- Frits and Fittings: Check the frits for integrity and ensure the fittings are clean and free of debris.

- Correct Orientation: Align the column with the flow direction as indicated by the manufacturer’s markings.

- Reattach the Column: Carefully connect the column to the HPLC system’s tubing finger-tight first.

- Tightening: Using the wrenches, tighten the fittings according to the manufacturer’s recommendations. Avoid overtightening.

Verification before Analysis:

Before starting your analysis, verify proper installation with these steps:

- Leak Check: Turn on the pump at a low flow rate and gradually increase it to the desired operating pressure. Monitor for any leaks at the connections.

- System Suitability Test: Run a system suitability test with a standard mixture. Ensure peak shapes, resolution, and retention times meet established criteria.

- Comparison (Optional): If available, compare the performance of the reinstalled column with a correctly installed reference column using the same mobile phase and sample. Consistent results between the two strengthen the confirmation of proper installation.

Additional Tips:

- When re-installing, apply a light touch when tightening the fittings. Overtightening can damage the column.

- If leaks persist, consult the manufacturer’s recommendations or seek assistance from a qualified service technician.

- Consider keeping a record of column installations, including the date and any observations made. This can be helpful for future troubleshooting.

By following these steps and tips, you can reinstall your HPLC column correctly and ensure optimal performance for your analytical experiments. Remember, proper installation protects your valuable column and guarantees reliable results.