From laboratories and research centers to classrooms and industry, the term “dead volume” echoes across the scientific community. However, its real significance often remains obscured to many. Dead volume, a critical concept every scientist should understand, can influence the efficiency and outcome of experiments. Let’s dive in to unravel its mysteries.

What is Dead Volume?

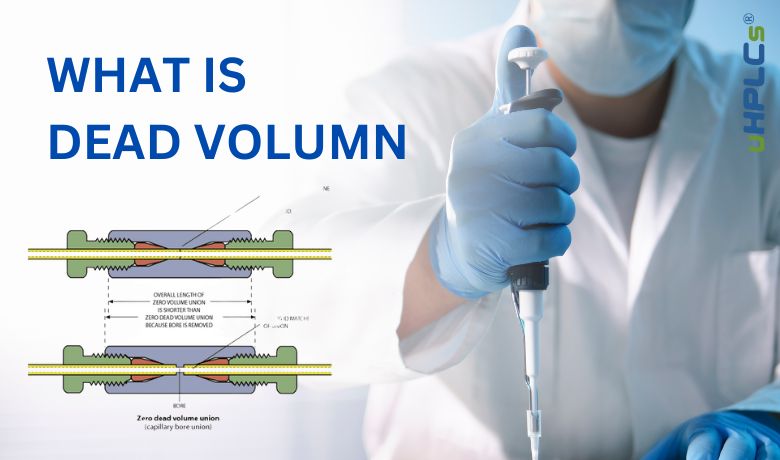

In short, In HPLC, dead volume refers to the volume of mobile phase (liquid that moves through the column carrying the sample) that is necessary to carry an unretained compound from the point of injection to the detector. Simply put, it’s the volume through which a solute passes without interacting with the stationary phase (the material inside the column that interacts with the sample components).

This volume is predominantly found within the HPLC system’s tubing, connectors, and fittings, but also includes the void volume of the column itself.

Implications of Dead Volume in HPLC

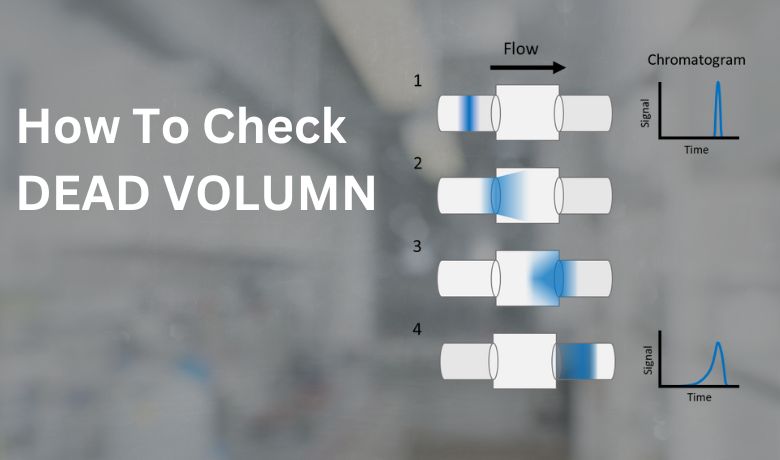

HPLC dead volume is particularly critical because it directly influences the efficiency and resolution of the separation process. If the dead volume is too large, it can lead to band broadening (spreading out of sample components), which reduces resolution and complicates the identification and quantification of sample components. This band broadening occurs because an excess dead volume creates a path of least resistance, causing the analyte to spread out and elute at different times.

The Importance of Dead Volume in Scientific Research

Understanding dead volume is crucial, especially in fields like chemistry, biology, and pharmaceutical research. It plays a pivotal role in analytical chromatography, determining fluid dynamics in microfluidic systems, and even influencing bioreactor performance. Let’s delve deeper into its significance.

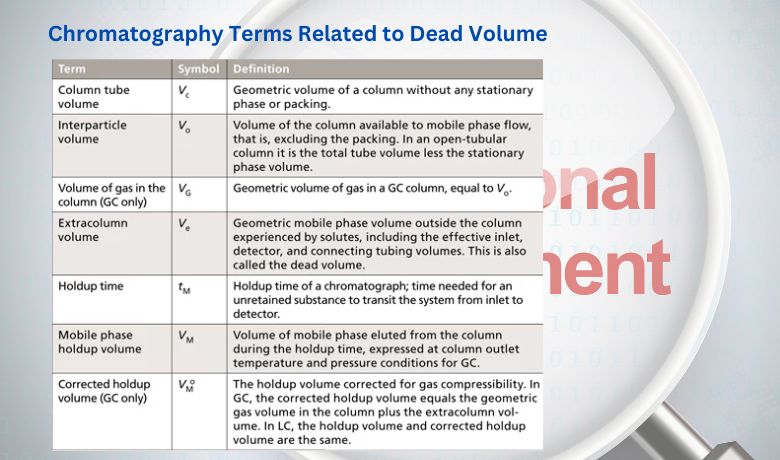

Dead Volume in Chromatography

In chromatography, dead volume is the minimum volume of mobile phase needed to elute a solute from the column. Larger dead volumes often lead to decreased separation efficiency and peak broadening. Thus, a clear comprehension of dead volume dynamics can significantly enhance the efficacy of chromatographic techniques.

Dead Volume in Microfluidics

Microfluidic systems, vital to fields like medical diagnostics and DNA sequencing, also deal with dead volume issues. In these systems, dead volume refers to the fluid retained in the device after dispensing. Excessive dead volume can impact the precision of fluid dispensing, potentially skewing experimental results.

Dead Volume in Bioreactors

Bioreactors are another domain where dead volume has considerable importance. Dead volume, or the un-agitated fluid in bioreactors, can affect cell culture processes and product yield, thereby influencing the effectiveness and profitability of biotechnological operations.

Dead Volume: A Key Player in Chromatographic Separation Efficiency

In the world of chromatography, dead volume holds a critical position. Its role is closely tied to the efficiency of separation and can greatly influence the results of an analysis. But what is this impact, and why is it so profound? Let’s dive deeper into this.

The Impact of Dead Volume on Separation Efficiency

Separation efficiency in chromatography refers to the ability of a chromatographic system to distinguish between different compounds in a mixture. The higher the separation efficiency, the better the system can differentiate individual components and produce distinct peaks in the chromatogram.

Dead volume directly impacts separation efficiency by influencing the width and shape of these peaks. In a system with excessive dead volume, the mobile phase (the liquid or gas that carries the sample through the system) has more space to move around, and the compounds in the sample can take different paths. This divergence can cause some portions of the sample to travel through the system faster than others – a phenomenon known as band broadening.

Band Broadening: The Result of Excessive Dead Volume

Band broadening leads to the spreading out of sample components, causing them to elute over a larger volume. This broadening directly results in wider peaks in the chromatogram, which can overlap with each other and make it challenging to distinguish individual components.

Moreover, band broadening also impacts peak shape. Ideally, chromatographic peaks should be symmetrical and narrow for the best resolution. However, excessive dead volume can cause peaks to become asymmetric and tail, reducing the resolution of the analysis.

Striving for Efficiency: The Need to Minimize Dead Volume

Given the significant influence of dead volume on separation efficiency, peak width, and peak shape, it is essential to minimize this parameter. This goal can be achieved through careful system design, including selecting columns and tubing with minimal internal volume, and using fittings and connectors designed to reduce dead volume.

How to Calculating Dead Volume: A Practical Guide

Knowing how to calculate dead volume can be crucial for maintaining accuracy and efficiency in various scientific fields, from chromatography to fluid dynamics. Here are some general steps to compute dead volume in a system:

- Identify the Components: First, identify all the components of your system where dead volume might be present. This could include elements such as tubing, valves, connectors, and chambers.

- Determine the Volumes: Next, determine the volume of each component. The method for doing this can vary depending on the specific component. For a simple cylindrical tube, the volume can be calculated using the formula: volume = πr²l, where r is the radius and l is the length. For other components, you may need to refer to manufacturer specifications or use methods like water displacement.

- Add the Volumes: After calculating the volume for each component, add them all together. The sum of these volumes is your system’s dead volume.

1. Calculating Dead Volume in Chromatography

For chromatographic applications, there’s a specific way to calculate dead volume (also known as void volume, V0). It is typically calculated by injecting an unretained compound (a compound that doesn’t interact with the stationary phase) into the chromatographic system. The dead volume can be computed from the retention time of this compound using the formula:

V0 = F * t0

where F is the flow rate (typically in ml/min) and t0 is the retention time of the unretained compound (in minutes).

2. Estimating Dead Volume in Microfluidics and Bioreactors

In microfluidic systems or bioreactors, dead volume estimation can be more complex due to the system’s intricacies. In such cases, it often requires creating a detailed computational model of the system’s fluid dynamics, using software specifically designed for this purpose.

Mitigating the Implications of Dead Volume

While dead volume is often unavoidable, there are ways to minimize its impact. Through optimal experimental design and proper equipment selection, you can mitigate the implications of dead volume in your scientific work.

Optimal Experimental Design

One way to tackle dead volume is through careful experimental design. For chromatography, choosing columns with smaller diameters can reduce dead volume. In microfluidic systems, designing compact and efficient layouts minimizes fluid retention.

Proper Equipment Selection

Choosing the right equipment can also help control dead volume. For instance, selecting syringes, tubes, or valves with minimal internal volume can significantly reduce dead volume in bioreactors and microfluidic systems.

Managing HPLC Dead Volume

To maintain the efficiency of HPLC systems, it’s important to minimize dead volume. This can be achieved by:

- Using shorter and narrower-bore tubing: This reduces the physical volume in which no interaction occurs between the solute and the stationary phase.

- Minimizing the use of connectors and fittings: Every added piece introduces potential extra dead volume.

- Employing low-dead-volume components: Several manufacturers offer HPLC components specifically designed to minimize dead volume.

By understanding and managing HPLC dead volume, scientists can ensure that their analyses are as accurate and precise as possible, strengthening the reliability of their results and the validity of their research.

Technological Advancements Combatting Dead Volume

Technology is playing a significant role in managing and reducing dead volume. Devices like low-dead-volume connectors and nanoliter dispensing systems have emerged as effective tools in battling the implications of dead volume.

Low-dead-volume Connectors

These connectors are specifically designed to minimize fluid retention, making them ideal for microfluidic and chromatography applications. By reducing dead volume, these connectors enhance fluid transfer efficiency and ensure more accurate results.

Nanoliter Dispensing Systems

Nanoliter dispensing systems are another technological breakthrough combatting dead volume. These systems precisely dispense minuscule volumes, thereby minimizing fluid retention in the dispensing device. This precision significantly improves the accuracy of high-throughput screening and drug discovery processes.

Dead Volume: An Unseen Yet Crucial Parameter

Though often overlooked, dead volume significantly impacts the outcome of numerous scientific processes. Understanding its presence, influence, and control mechanisms are crucial for all scientists, regardless of their specific discipline.

Conclusion

As we have seen, dead volume is an integral concept every scientist should grasp. Its presence in equipment used across scientific fields, from chromatography to microfluidics and bioreactors, can greatly affect experimental efficiency and results.

While often overlooked, recognizing dead volume is only the first step. Understanding its implications and knowing how to mitigate its effects through optimal experimental design and appropriate equipment selection is crucial. Moreover, with the help of technological advancements such as low-dead-volume connectors and nanoliter dispensing systems, we are not just mitigating but actively combatting the impacts of dead volume.

In the world of scientific research, where precision is paramount, even the seemingly small factor of dead volume can have a significant impact. Thus, a comprehensive understanding of dead volume equips scientists with a vital tool for improving accuracy, efficiency, and ultimately, the validity of their work.

In summary, dead volume might be invisible, but its influence is undeniable. So let’s embrace this concept, dive deeper into its understanding, and leverage this knowledge to set a new benchmark in scientific research.

Contact uHPLCs

Are you striving to optimize your HPLC experiments? Looking to minimize the impact of dead volume in your chromatographic analyses? We at uHPLCs can help you! We specialize in providing top-quality HPLC consumables and components that are designed to help you reduce dead volume and improve your separation efficiency.

Don’t let dead volume hamper the potential of your experiments. With our advanced HPLC supplies, including low-dead-volume connectors, narrow-bore tubing, and carefully designed fittings, you can take control of dead volume and ensure that your results are as accurate and reliable as possible.

Our team of dedicated HPLC specialists is ready to work with you, understand your specific needs, and provide tailored solutions that align with your HPLC procedures. Let’s enhance your laboratory’s performance together.