Liquid chromatography (LC) is a powerful analytical technique widely used in various industries, including pharmaceuticals, forensics, environmental science, and food and beverage analysis. It separates and identifies components within a complex mixture by passing a liquid mobile phase through a stationary phase packed within a column.

Guard columns, also known as pre-columns, are short columns placed before the analytical column in an LC system. They play a crucial role in protecting the analytical column, leading to several advantages:

- Extended column lifetime: Guard columns act as a first line of defense, trapping contaminants and particulates that could damage the delicate packing material of the analytical column. This significantly reduces wear and tear, extending the analytical column’s lifespan and saving you money on replacements.

- Improved chromatographic performance: By removing contaminants that can interfere with the separation process, guard columns help maintain consistent peak shapes, retention times, and resolution. This leads to more reliable and reproducible results in your LC analyses.

- Reduced cost per analysis: By protecting the analytical column and ensuring better performance, guard columns ultimately reduce the cost per analysis. You’ll spend less on frequent column replacements and re-calibrations.

Understanding Liquid Chromatography and Guard Columns

1.1 Liquid Chromatography: Principle and Applications

Liquid chromatography (LC) is a separation technique based on the differential interaction of compounds with two phases: a mobile phase (liquid) that flows through the system and a stationary phase (solid) packed within a column.

Principle: As the mobile phase carries the sample mixture through the column, each component interacts differently with the stationary phase. Compounds with a stronger affinity for the stationary phase will spend more time interacting with it and elute (exit) the column later. Conversely, compounds with a weaker affinity will elute earlier.

Applications: LC is a versatile technique used in diverse fields like:

- Pharmaceutical analysis: Identifying and quantifying drugs, impurities, and degradation products.

- Environmental analysis: Detecting pollutants in water, soil, and air samples.

- Food and beverage analysis: Studying flavors, additives, and contaminants.

- Forensics analysis: Examining biological samples for evidence.

1.2 Guard Columns: Definition and Basic Function

Guard columns, also known as pre-columns, are short columns placed upstream of the main analytical column in an LC system. They act as a protective barrier for the analytical column by:

- Filtering out particulates: These can be present in the sample or mobile phase and can clog the frit (a porous filter) at the inlet of the analytical column, hindering its performance.

- Adsorbing strongly-retained compounds: Some sample components can have a very strong affinity for the stationary phase and can irreversibly bind to it, permanently altering the column’s performance. Guard columns use the same or similar packing material as the analytical column to attract and trap these compounds before they reach the main column.

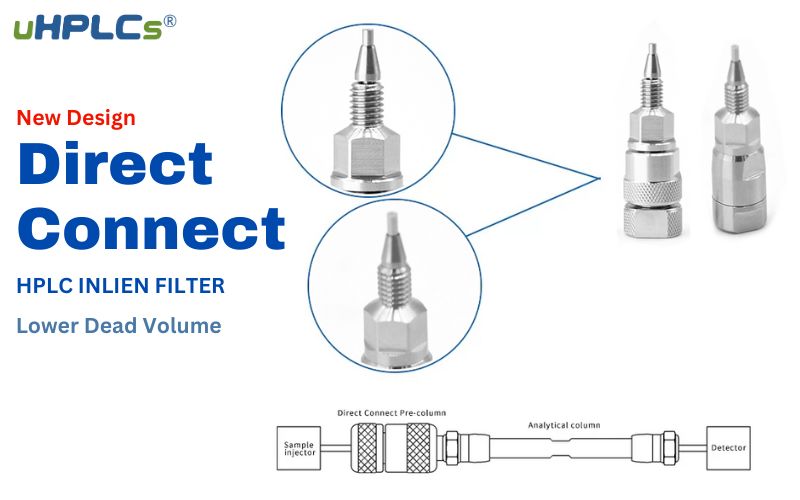

1.3 Structure and Placement of Guard Columns

Guard columns are typically much shorter (5-10 cm) and have a smaller diameter compared to the analytical column. They are connected in-line between the injector and the analytical column using specialized frits or fittings. This placement ensures that the sample passes through the guard column first, where it is “cleaned” before reaching the analytical column for separation.

By understanding the role of guard columns in protecting and preserving the analytical column, we can appreciate their crucial contribution to reliable and cost-effective LC analyses. The next section will explore the various benefits of using guard columns in greater detail.

The Importance of Guard Columns in HPLC System

2.1 Protecting Analytical Columns: Preventing Contamination and Extending Lifespan

Analytical columns in LC systems are intricate and costly components. Their performance relies heavily on the delicate packing material housed within the column. Guard columns act as a shield against various threats that could damage the analytical column:

- Particulate matter: Samples and mobile phases might contain microscopic particles that can clog the frit of the analytical column, hindering flow and reducing separation efficiency. Guard columns, with their larger pore size, trap these particles before they reach the main column, preserving its performance.

- Chemical contaminants: Impurities not related to the target analytes can be present in samples or mobile phases. These can irreversibly bind to the stationary phase, altering the column’s selectivity and reducing its effectiveness. Guard columns, packed with similar material to the analytical column, attract and retain these contaminants, preventing them from affecting the analytical separation.

By shielding the analytical column from these harmful factors, guard columns significantly extend its lifespan, saving you the cost and effort of frequent replacements.

2.2 Cost-Effectiveness: Reducing the Need for Frequent Column Replacements

Analytical columns represent a significant investment in any LC system. Replacing them due to contamination or damage can be expensive and disruptive to your workflow. Guard columns offer a cost-effective solution by offering several advantages:

- Reduced frequency of column replacements: By protecting the analytical column from damage and contamination, guard columns significantly extend its usable life. This translates to fewer replacements, reducing overall costs associated with column maintenance.

- Lower cost of replacement: Guard columns themselves are much smaller and simpler than analytical columns. They usually utilize less packing material and are often disposable or refillable, leading to a lower overall cost per analysis.

By minimizing the need for frequent and expensive analytical column replacements, guard columns contribute to a more cost-efficient operation of your LC system.

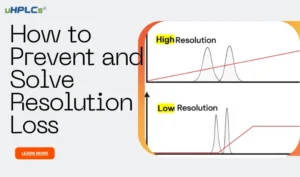

2.3 Improved Column Efficiency and Resolution: How Guard Columns Contribute

Guard columns indirectly contribute to improved chromatographic performance by ensuring a cleaner and more consistent analytical environment:

- Consistent peak shape and retention times: Guard columns remove contaminants that can interfere with the interaction of your target analytes with the stationary phase. This results in more consistent peak shapes and retention times, leading to more reliable and reproducible data.

- Enhanced resolution: Contaminants can also mask or overlap peaks of interest, hindering clear separation. By removing these interferences, guard columns help improve the resolution between peaks, allowing for easier identification and quantification of your target analytes.

By promoting consistent and clean chromatography, guard columns ultimately contribute to more accurate and reliable results in your LC analyses.

Types of Guard Columns

Guard columns come in various configurations to cater to diverse needs in LC analyses. Understanding the available options helps you choose the most suitable one for your specific application.

3.1 Material and Size:

Guard columns typically utilize the same stationary phase material as the analytical column or a closely related material with similar selectivity. This ensures they effectively capture contaminants that might interfere with the analytical separation.

However, guard columns often differ in size from their analytical counterparts:

- Length: Guard columns are typically much shorter, ranging from 5 to 10 cm, compared to the analytical column’s length (usually 15-25 cm or even longer).

- Diameter: Their diameter can be the same or slightly smaller than the analytical column, depending on the specific application and system pressure limitations.

3.2 Compatibility Considerations:

Choosing the right guard column is crucial for optimal performance. Here are key factors to consider:

- Compatibility with the analytical column: Ensure the guard column uses the same or a compatible stationary phase as your analytical column. This allows it to effectively target and remove interfering compounds that might interact similarly with the main column.

- Sample characteristics: Consider the types of contaminants present in your samples. If you anticipate high levels of particulates, a guard column with a larger pore size might be beneficial for enhanced filtration.

- Flow rate and pressure limitations: Choose a guard column with compatible flow rate and pressure ratings for your LC system. Exceeding these limits can damage the guard column and compromise its performance.

By carefully considering the material, size, and compatibility of the guard column, you can ensure it effectively protects your valuable analytical column and contributes to optimal performance in your LC analyses.

We will delve deeper into the practical aspects of using guard columns in the next section, including their selection, installation, and maintenance.

Popular HPLC Guard Column Types

| Stationary Phase | Guard Column Type | Typical Length (cm) | Size (mm) | Inner Diameter (ID) (mm) |

|---|---|---|---|---|

| C18 | Universal | 5, 10 | 2.1 x 5, 3.0 x 5, 4.6 x 5 | 2.1, 3.0, 4.6 |

| C18 | High Performance | 5, 10 | 2.1 x 5, 3.0 x 5, 4.6 x 5 | 2.1, 3.0, 4.6 |

| C18 | Polar Embedded | 5, 10 | 2.1 x 5, 3.0 x 5, 4.6 x 5 | 2.1, 3.0, 4.6 |

| C8 | Universal | 5, 10 | 2.1 x 5, 3.0 x 5, 4.6 x 5 | 2.1, 3.0, 4.6 |

| C8 | Polar Embedded | 5, 10 | 2.1 x 5, 3.0 x 5, 4.6 x 5 | 2.1, 3.0, 4.6 |

| Phenyl | Universal | 5, 10 | 2.1 x 5, 3.0 x 5, 4.6 x 5 | 2.1, 3.0, 4.6 |

| Cyano | Universal | 5, 10 | 2.1 x 5, 3.0 x 5, 4.6 x 5 | 2.1, 3.0, 4.6 |

| Silica | Normal Phase | 5, 10 | 2.1 x 5, 3.0 x 5, 4.6 x 5 | 2.1, 3.0, 4.6 |

| Ion-Exchange | Cation Exchange | 5, 10 | 2.1 x 5, 3.0 x 5, 4.6 x 5 | 2.1, 3.0, 4.6 |

| Ion-Exchange | Anion Exchange | 5, 10 | 2.1 x 5, 3.0 x 5, 4.6 x 5 | 2.1, 3.0, 4.6 |

When to Use a Guard Column

Guard columns are a valuable investment for most LC users, but their specific benefits become even more pronounced under certain circumstances:

4.1 Situations and Samples:

- Samples with high particulate content: Samples from environmental sources, crude extracts, or poorly filtered solutions may contain microscopic particles that can clog the frit of the analytical column. Implementing a guard column with a larger pore size effectively traps these particles, protecting the main column.

- Samples with strongly-retained components: Some samples may contain components that strongly bind to the stationary phase of the analytical column, altering its performance over time. Guard columns, packed with similar material, act as a “decoy,” attracting and retaining these interfering compounds before they reach the main column.

- Frequent column switching: If you routinely switch between different analytical columns or stationary phases, using guard columns for each specific type can help minimize cross-contamination and ensure optimal performance when switching between methods.

- New column conditioning: When using a new analytical column, a guard column can be employed during the initial conditioning process. This helps protect the main column from any potential contaminants or irregularities that might be released during the conditioning stage.

4.2 Industry-Specific Examples:

Pharmaceutical analysis: Samples may contain excipients or degradation products that can foul the analytical column. Guard columns can help ensure the purity and effectiveness of the analysis.

Environmental testing: Samples collected from contaminated environments may contain high levels of particulates or complex matrices. Guard columns can protect the analytical column from these interferences and ensure accurate detection of environmental pollutants.

Food and beverage analysis: Complex food matrices can contain various interfering components. Implementing guard columns helps maintain column performance and facilitates reliable analysis of food additives, contaminants, and other components.

By understanding these scenarios and industry-specific examples, you can make informed decisions about when employing a guard column can significantly benefit your LC analyses.

How to Choose and Install a Guard Column

5.1 Selecting a Guard Column:

Choosing the right guard column is crucial for maximizing its effectiveness and protecting your analytical column. Here are key factors to consider:

Compatibility: Select a guard column with the same stationary phase as your analytical column or a compatible material with similar selectivity. This ensures it effectively targets and removes interfering compounds.

Dimensions:

- Length: Generally, choose a guard column that is 5-10 cm long, significantly shorter than your analytical column.

- Diameter: The diameter can be the same as your analytical column or slightly smaller, depending on pressure limitations and application needs. Consider a larger diameter for samples with high particulate content.

Particle size: Choose a guard column with the same particle size as your analytical column if possible. This ensures minimal dead volume and similar flow characteristics. However, a slightly larger particle size can be beneficial for high-pressure systems or samples with abundant particulates.

Pore size: The pore size should be compatible with your mobile phase and sample matrix. If you anticipate high levels of particulates, consider a guard column with a slightly larger pore size to enhance filtration without compromising chromatographic performance.

5.2 Installing a Guard Column:

Always consult your LC system’s manual and safety protocols before installation. Here’s a general guide:

- Gather your materials: You’ll need the guard column, connecting fittings, wrenches, and cleaning solvent.

- Turn off the LC system and purge the lines with solvent.

- Locate the guard column holder on your LC system. This is typically situated between the injector and the analytical column inlet.

- Attach the guard column to the holder using the recommended fittings. Tighten them carefully with the wrenches, following the manufacturer’s instructions and torque specifications. Avoid over-tightening, which can damage the column or connections.

- Connect the guard column to the injector and analytical column using appropriate tubing and fittings. Ensure proper finger-tightening and consult the manual for specific connection details.

- Turn on the LC system and set the flow rate according to the guard column’s specifications.

- Condition the guard column by running a blank mobile phase through the system for the recommended time. This removes any contaminants present in the column.

Remember:

- Always handle the guard column with care to avoid damaging the frit or packing material.

- Refer to your specific LC system and guard column manufacturer’s instructions for detailed installation procedures and safety precautions.

By following these steps and considering the key selection factors, you can ensure your guard column is properly chosen and installed, contributing to optimal performance and protection of your valuable analytical column.

Maintenance and Troubleshooting

6.1 Guard Column Maintenance:

Proper maintenance practices are essential for maximizing the lifespan and performance of your guard column. Here are some key recommendations:

- Regular replacement: Replace your guard column regularly, especially if you are analyzing samples with high particulate content or strongly-retained compounds. The frequency will depend on sample characteristics and usage patterns. Consult your column and instrument manuals for recommended replacement intervals.

- Cleaning: You can occasionally clean your guard column to remove accumulated contaminants, depending on the specific column type and manufacturer’s recommendations. Follow the manufacturer’s instructions for appropriate cleaning procedures and solvents. Remember, not all guard columns are designed to be cleaned.

- Proper storage: When not in use, store your guard column in a clean and dry environment, following the manufacturer’s recommendations. This helps prevent contamination and degradation of the packing material.

6.2 Troubleshooting Common Issues:

Guard columns, while highly beneficial, can sometimes encounter issues. Here are some common problems and troubleshooting tips:

Problem: Increased backpressure: This can indicate a clogged frit or accumulated contaminants in the guard column.

Possible Solutions:

- Replace the guard column.

- Attempt cleaning the guard column if the manufacturer allows it.

- Check for blockages in the injector or other parts of the system.

Problem: Peak tailing or broadening: This can be caused by various factors, including overloading the guard column or contamination affecting the stationary phase.

Possible Solutions:

- Reduce the sample injection volume.

- Replace the guard column.

- Check for potential leaks in the system.

Problem: Inconsistent retention times: This can indicate contamination or degradation of the guard column packing material.

Possible Solutions:

- Replace the guard column.

- Check for system stability and proper column equilibration.

Remember:

- Always consult your specific guard column and LC system’s manuals for detailed maintenance and troubleshooting guidance.

- If the issue persists, seek assistance from your LC instrument manufacturer or a qualified service provider.

By following these maintenance and troubleshooting tips, you can ensure your guard column operates efficiently and effectively for a longer period, ultimately contributing to reliable and cost-effective LC analyses.

Conclusion:

Guard columns represent a valuable tool in LC, offering significant benefits like extended analytical column life, improved chromatographic performance, and cost-effectiveness. By understanding their function, choosing the right type, and implementing proper maintenance practices, you can leverage the full potential of guard columns in your LC analyses.