High-performance liquid chromatography (HPLC) is a versatile analytical technique used to separate, identify, and quantify the components within complex liquid mixtures. Its precision, sensitivity, and broad application range have made it indispensable in modern chemistry.

An HPLC system primarily consists of:

- A high-pressure pump to deliver the liquid solvent (mobile phase)

- An injector for introducing the sample

- A column filled with the stationary phase where separation occurs

- A detector to measure the separated components

- A data system for instrument control and analysis

The heart of the HPLC system is the column. Packed with tiny silica particles (typically 3-5 micrometers), it’s where the compounds in the sample are physically separated. To achieve efficient separation with these small particles, the system operates at high pressures.

1. Understanding HPLC Column Packing

Definition and Purpose of Column Packing

Column packing is the process of filling an HPLC column with a solid material, known as the stationary phase. The stationary phase is crucial for separating components in a liquid mixture. Its physical and chemical properties determine the separation selectivity of the column.

Types of Packing Materials

There are primarily three types of packing materials used in HPLC columns:

Silica-based

- Most common type of packing material due to its high efficiency and versatility.

- Composed of silica particles with varying pore sizes and surface chemistries.

- Offers excellent peak shape and resolution for a wide range of compounds.

- Susceptible to pH and temperature extremes.

Polymer-based

- Made from organic polymers, providing alternative selectivity compared to silica.

- Suitable for analyzing compounds that are unstable or interact strongly with silica.

- Generally more stable at extreme pH and temperature conditions.

- Often exhibit lower efficiency compared to silica-based packings.

Hybrid materials

- Combine the characteristics of silica and polymer materials.

- Offer improved efficiency, stability, and selectivity compared to pure silica or polymer columns.

- Provide a wider range of applications.

Comparison of Different Packing Materials

| Feature | Silica-based | Polymer-based | Hybrid |

|---|---|---|---|

| Efficiency | High | Moderate | High |

| Selectivity | Broad | Specific | Broad |

| pH stability | Limited | Wide | Wide |

| Temperature stability | Limited | Wide | Wide |

| Cost | Moderate | High | High |

Advantages and Disadvantages

- Silica-based: High efficiency, wide range of selectivity, cost-effective, but limited pH and temperature stability.

- Polymer-based: Wide pH and temperature stability, suitable for unstable compounds, but lower efficiency and limited selectivity.

- Hybrid: Combines advantages of both silica and polymer, offering high efficiency, wide selectivity, and improved stability, but higher cost.

Applications in Various Industries

HPLC with different column packings is employed across various industries:

- Pharmaceutical: Analysis of drug impurities, stability studies, and quality control.

- Environmental: Detection of pollutants in water, soil, and air.

- Food and beverage: Quality control, analysis of additives, and contaminant detection.

- Chemical: Analysis of reaction products, impurities, and process monitoring.

- Biotechnology: Purification and characterization of biomolecules.

The choice of column packing depends on the specific analytical requirements of the application.

2. Types of HPLC Column Packing

1.Reverse-Phase Packing

A> Description and Mechanism:

*Stationary phase: Non-polar (e.g., C18, C8) bonded to silica particles.

*Mobile phase: Polar solvent (e.g., water, methanol, acetonitrile).

*Separation mechanism: Based on the differential partitioning of solutes between the non-polar stationary phase and the polar mobile phase.

Less polar compounds have a stronger affinity for the stationary phase and elute later.

B> Common Uses and Benefits:

*Most widely used type of HPLC column.

*Excellent for separating a wide range of compounds, including pharmaceuticals, environmental pollutants, and biological molecules.

*Compatible with aqueous mobile phases, making it suitable for many samples.

*Offers good reproducibility and robustness.

2. Normal-Phase Packing

A>Description and Mechanism:

*Stationary phase: Polar (e.g., silica gel).

*Mobile phase: Non-polar solvent (e.g., hexane, heptane).

*Separation mechanism: Based on the polarity of the solutes.

Polar compounds interact more strongly with the polar stationary phase and are retained longer.

B>Applications and Benefits:

*Used for separating polar compounds, such as sugars, lipids, and some pharmaceuticals.

*Effective for compounds that are not soluble in aqueous mobile phases.

*Can provide unique selectivity compared to reverse-phase chromatography.

3. Ion-Exchange Packing

A>Description and Mechanism:

*Stationary phase: Contains charged functional groups (e.g., cation exchange with sulfonic acid groups, anion exchange with quaternary ammonium groups).

*Mobile phase: Aqueous buffer with varying ionic strength and pH.

*Separation mechanism: Based on electrostatic interactions between charged analytes and the oppositely charged functional groups on the stationary phase.

B>Key Applications:

*Separation of ionic compounds, such as proteins, peptides, amino acids, and inorganic ions.

*Purification of biomolecules.

*Water analysis for ion determination.

4. Size-Exclusion Packing

A> Description and Mechanism:

*Stationary phase: Porous particles with a defined pore size distribution.

*Mobile phase: Compatible solvent for the sample.

*Separation mechanism: Based on the molecular size of the analytes.

Larger molecules are excluded from the pores and elute first, while smaller molecules

can enter the pores and are retained longer.

B>Uses in Protein and Polymer Analysis:

*Determination of molecular weight and size distribution of proteins, polymers, and other macromolecules.

*Fractionation of complex mixtures based on size.

*Purification of biomolecules.

5. Affinity Packing

A>Description and Mechanism:

*Stationary phase: Contains specific ligands covalently attached to the support matrix.

*Mobile phase: Compatible buffer solution.

*Separation mechanism: Based on specific interactions between the analyte and the immobilized ligand.

B>Specific Applications in Biochemistry:

*Purification of enzymes, antibodies, and other biomolecules.

*Isolation of specific target molecules from complex mixtures.

*Analysis of biomolecular interactions.

3. Essential Tools for HPLC Column Packing

Column Frits and Filters

Importance in Maintaining Column Efficiency:

Column frits and filters are crucial for preventing particulate matter from entering the HPLC column, which can lead to increased back pressure, clogging, and reduced column efficiency. By filtering out particulates, these components help maintain consistent flow rates and prolong the column’s lifespan.

Types and Materials:

- Pre-column Filters: Installed before the column to filter out particulates from the mobile phase and sample.

- In-line Filters: Positioned within the HPLC system to provide continuous filtration.

- Materials: Typically made from stainless steel or PEEK (polyether ether ketone) to ensure chemical compatibility and durability

Guard Columns

Role in Protecting the Main Column:

Guard columns are short columns placed between the injector and the analytical column. They trap contaminants and particulates, preventing them from reaching the main column and thereby extending its serviceable life

Types and Selection Criteria:

- Cartridge-Type Guard Columns: Contain packing material similar to the analytical column and are replaceable.

- Packed Guard Columns: Short columns packed under high pressure, suitable for samples with high concentrations of interfering compounds.

- Selection Criteria: Compatibility with the analytical column, operating pressure, and specific application requirements

Column Couplers and Adapters

Ensuring Proper Connections and Reducing Dead Volume:

Column couplers and adapters are used to connect different parts of the HPLC system, ensuring proper alignment and minimizing dead volume. This is essential for maintaining high efficiency and preventing peak broadening in chromatographic separations.

Packing Stations

Description and Use in Lab Settings:

HPLC Packing stations are specialized setups used for packing HPLC columns with stationary phase material.

Also called HPLC Column Packing Hardware.

They ensure uniform packing density and proper distribution of particles, which is critical for achieving high-resolution separations. These stations typically include equipment for controlling pressure and flow during the packing process.

Flow Controllers and Pressure Gauges

Maintaining Optimal Flow Rates and Pressures:

Flow controllers and pressure gauges are essential for monitoring and maintaining the optimal flow rates and pressures in an HPLC system. They help ensure consistent performance and prevent damage to the column and other system components due to pressure fluctuations.

Solvent Filters

Ensuring Purity of Solvents and Protecting Column Packing:

Solvent filters are used to remove particulates and dissolved gases from the mobile phase. This is crucial for protecting the column packing from contamination and ensuring the purity of solvents, which in turn improves the reliability and reproducibility of HPLC analyses.

4. Maintenance and Troubleshooting

Tips for Extending the Life of HPLC Columns

- Proper Storage:

- Store columns in 100% acetonitrile for long-term storage and avoid buffered eluents to prevent precipitation within the column bed.

- Ensure the column is tightly sealed with end plugs to prevent drying out.

- Routine Monitoring:

- Regularly check the column’s performance using standards to detect any changes in retention characteristics.

- Use filtered and degassed mobile phases to avoid introducing particulates and gases that can damage the column.

- Switching Mobile Phases:

- Only switch between miscible mobile phases to prevent precipitation of salts within the column.

- Cleaning and Flushing:

- Flush the column with HPLC grade water followed by acetonitrile if buffered mobile phases were used.

- Perform routine cleaning cycles to remove contaminants and prevent fouling.

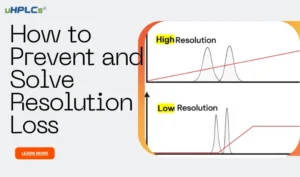

Common Issues and How to Resolve Them

- Peak Tailing:

- Cause: Column contamination or degradation of the stationary phase.

- Solution: Clean the column by flushing with appropriate solvents. Replace the column if peak tailing persists.

- Pressure Increases:

- Cause: Blockages due to particulate matter or precipitated buffers.

- Solution: Check for blockages in the system by measuring pressure with and without the column. Flush or backflush the column to clear any blockages.

- Baseline Noise:

- Cause: Contaminants in the mobile phase or system.

- Solution: Use high-purity solvents and ensure all mobile phases are properly filtered and degassed. Clean the system thoroughly.

Cleaning and Regeneration of HPLC Columns

- Reverse Flow Flushing:

- Disconnect the column from the detector and flush it in the reverse direction with 5-10 column volumes of solvent to remove particulates and contaminants from the inlet frit.

- Column Restoration Procedures:

- Use specific cleaning solutions recommended by the column manufacturer to restore performance. Ensure all mobile phases are miscible to prevent precipitation during the cleaning process.

Best Practices for Storage and Handling

- Short-Term Storage:

- Store the column in the working mobile phase if it will be used again within two weeks.

- Long-Term Storage:

- Use a storage solvent that inhibits microbial growth, such as a mixture of 40% methanol and 60% water.

- Handling:

- Always use the column in the direction indicated on the label.

- Avoid exposing the column to extreme temperatures or pressures beyond its specified limits

Conclusion

Choosing the right HPLC column packing and tools is crucial for achieving accurate and reliable chromatographic results. Understanding the different types of column packing and their specific applications allows for more precise separation of compounds, leading to better analytical outcomes. By applying this knowledge, you can optimize your HPLC processes, ensuring high efficiency and reproducibility.

If you have any questions or need personalized advice on selecting the right HPLC column packing and tools for your specific needs, feel free to reach out.

Contact us via email at sales@uhplcs.com to discuss your HPLC requirements and get expert guidance.