1. Introduction: The Hidden Impact of Solvent Effects in HPLC

If you’ve ever observed baseline drift, unexpected baseline noise, or unstable detector signals in HPLC, your first reaction was probably familiar:

“Is the column aging?”

“Is the detector malfunctioning?”

These are reasonable assumptions — but in many real laboratory situations, neither is true.

In practice, a significant portion of unstable HPLC signals originates not from faulty hardware, but from something far more subtle and often overlooked: solvent effects.

Differences between solvents — particularly in gradient elution or mixed solvent systems — can quietly influence detector response, distort baselines, and reduce analytical reliability. Because these effects develop gradually and inconsistently, they are often misdiagnosed as column degradation or detector instability.

Fortunately, solvent-related signal disturbances are not unavoidable. A dedicated and increasingly popular solution exists: the Solvent Effect Eliminator.

2. What Are Solvent Effects in Liquid Chromatography?

In liquid chromatography, solvent effects refer to changes in detector response caused by differences in solvent properties rather than the presence or concentration of analytes.

In other words, the detector responds to the solvent itself — sometimes more strongly than to the compounds you actually care about.

Common sources of solvent effects include:

- Refractive index differences between mobile phase components

- UV absorption differences at the detection wavelength

- Solvent mismatch between the sample solvent and the mobile phase

- Rapid solvent composition changes during gradient elution

These factors are particularly problematic when the detector is highly sensitive to physical or optical changes in the mobile phase.

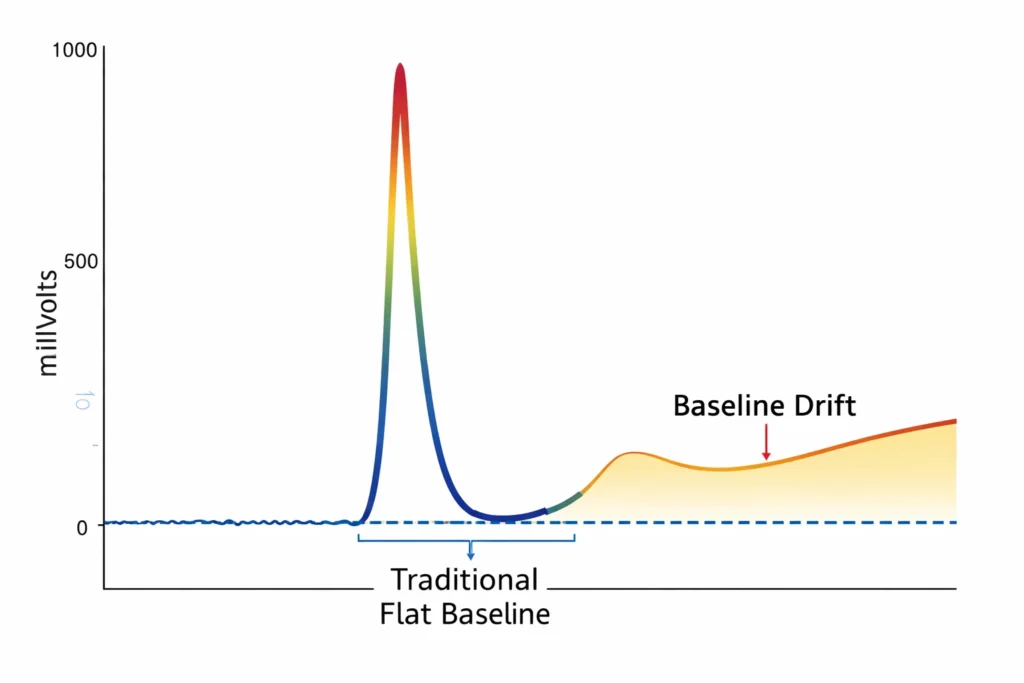

As a result, solvent effects often appear as:

- Baseline drift over time

- Increased baseline noise

- False peaks or irregular signal fluctuations

Keywords frequently associated with these problems include baseline drift, solvent mismatch, detector response variability, and signal instability — all common troubleshooting complaints in HPLC labs.

3. How Solvent Effects Affect Detector Performance

Solvent effects do not impact all detectors equally. Their influence depends strongly on the detection principle.

● UV Detectors

In UV detection, solvent effects arise primarily from differences in UV absorbance between mobile phase components.

Common consequences include:

- Background absorption shifts during gradient runs

- Baseline fluctuations as solvent composition changes

- Reduced signal clarity for low-level analytes

When solvent absorbance approaches the analyte’s absorbance wavelength, even small composition changes can significantly affect the baseline, making quantitative analysis less reliable.

● Refractive Index Detectors (RID)

Refractive Index Detectors are especially vulnerable to solvent effects.

Because RID directly measures changes in refractive index:

- Even minor solvent composition changes cause severe baseline drift

- Gradient elution becomes extremely challenging

- Long stabilization times are required between runs

Without additional control, maintaining a stable baseline in RID systems can be difficult — particularly in methods involving mixed solvents or temperature fluctuations.

● Sensitivity Impact

When solvent effects dominate detector response:

- Low-concentration analytes may be masked by baseline noise

- The signal-to-noise ratio (S/N) deteriorates

- Quantitative accuracy and repeatability suffer

This is especially critical in trace-level analysis, where analytical margins are already narrow.

4. What Is a Solvent Effect Eliminator?

A Solvent Effect Eliminator is a compact inline device installed upstream of the detector.

Its purpose is not to modify chromatographic separation, but to condition the solvent environment before detection.

In simple terms, it is designed to:

- Stabilize detector signals

- Reduce baseline noise and drift

- Improve run-to-run reproducibility

- Enhance overall data reliability

Importantly, a Solvent Effect Eliminator does not alter retention time, resolution, or peak separation. Instead, it improves how the detector perceives the eluent coming from the column.

5. How a Solvent Effect Eliminator Works

From an engineering perspective, the working principle is straightforward and practical.

A Solvent Effect Eliminator:

- Buffers or moderates solvent differences before they reach the detector

- Reduces sudden solvent composition shocks

- Smooths transitions during gradient elution

By controlling how solvent changes are presented to the detector, it minimizes non-analyte-related signal fluctuations.

The outcome is:

- A more stable detector environment

- Reduced solvent-induced disturbances

- An improved signal-to-noise ratio

There is no complex black-box mechanism involved — just intelligent control of solvent behavior at the most critical point in the system.

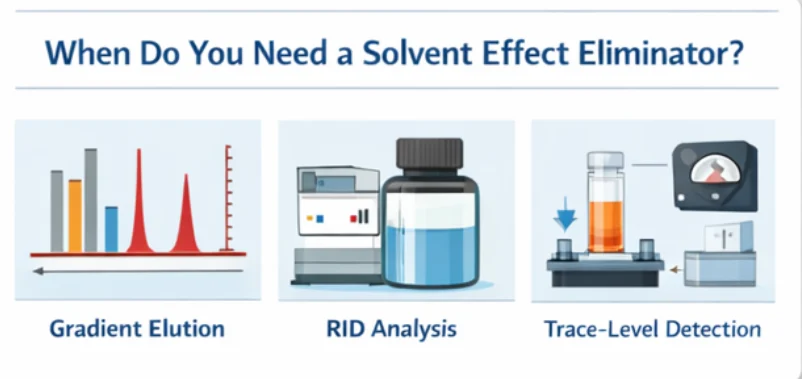

6. When Do You Need a Solvent Effect Eliminator?

You should seriously consider one if your method includes:

✔ Gradient elution methods

✔ Refractive Index Detection (RID)

✔ Trace-level or low-concentration analysis

✔ Complex or mixed solvent systems

✔ Persistent baseline instability despite mobile phase optimization

If you’ve optimized the column, mobile phase, and detector settings — and the baseline still won’t behave — solvent effects are likely the missing piece.

7. Solvent Effect Eliminator vs. Solvent Matching

These two strategies are often confused, but they address solvent effects from different angles.

Solvent matching is a method-level approach:

- Adjusting the sample solvent to closely match the mobile phase

- Effective in controlled situations

- Not always practical for complex samples or routine analysis

Solvent Effect Eliminators provide a hardware-level solution:

- Effective regardless of sample solvent constraints

- Ideal for high-throughput, regulated, or routine environments

- Reduce reliance on strict sample preparation control

In practice, these approaches are complementary rather than competitive. When used together, they offer the highest level of detector stability.

8. Conclusion: A Simple Tool for More Reliable HPLC Results

A Solvent Effect Eliminator is not a luxury accessory or an overengineered upgrade.

It is a practical, problem-solving tool designed to address one of the most common — and most misunderstood — sources of HPLC signal instability.

By stabilizing detector response, reducing noise, and improving reproducibility, it helps transform unstable chromatograms into data you can trust.

Sometimes, better chromatography doesn’t require a new column or detector —

just better control of the solvents you already use.

If solvent effects are compromising your baseline stability or masking low-level analytes, addressing them at the hardware level can make a measurable difference.

uHPLCs HPLC Peak Smooth Column (Solvent Effect Eliminator) is designed to minimize solvent-induced signal disturbances before they reach the detector. By stabilizing solvent transitions and reducing baseline noise, it helps deliver cleaner chromatograms, improved signal-to-noise ratios, and more reproducible results — especially in gradient elution and RID applications.

Instead of reworking your entire method, a compact inline solution may be all you need to restore confidence in your HPLC data.

Learn more about the HPLC Peak Smooth Column and see how it fits into your system