Introduction

Ever struggled to decide which HPLC column to use for your analysis? You’re not alone. With so many options—different particle sizes, materials, pore diameters, and surface chemistries—choosing the right column can feel overwhelming. Yet, this choice directly determines how sharp your peaks are, how well your compounds separate, and how long your column lasts.

So, where do you start?

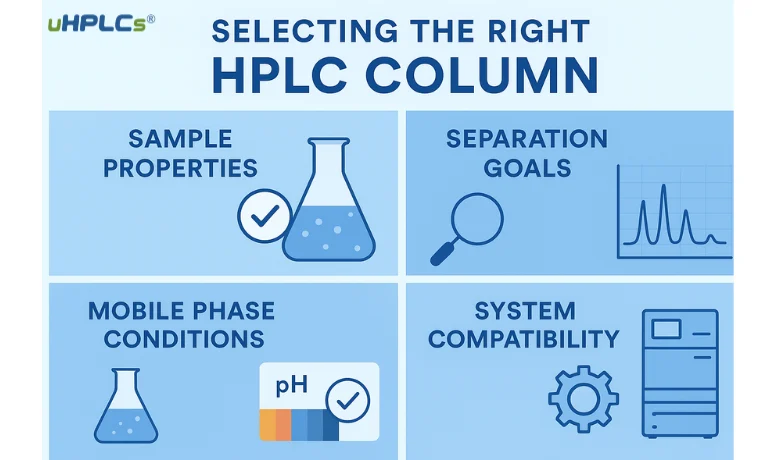

The smartest approach is to evaluate your choice across four key dimensions: sample properties, separation goals, mobile phase conditions, and system compatibility. Let’s explore each dimension in detail and learn how to make confident, science-based column selections.

1. Sample Properties: The Foundation of Column Selection

Your sample defines your column. Understanding the chemical characteristics of your analyte—its polarity, molecular weight, functional groups, and chemical stability—is the first and most essential step toward successful separation.

Polarity

Polarity dictates whether to use normal-phase or reversed-phase chromatography.

●Polar compounds such as sugars, organic acids, and amino acids typically favor normal-phase columns (e.g., amino, cyano, or silica-based stationary phases), where the stationary phase is polar and the mobile phase is non-polar.

●Non-polar compounds—including many pharmaceuticals, natural products, and hydrophobic organics—are best analyzed with reversed-phase columns (commonly C18, C8, or phenyl).

●Tip: Always consider the solubility of your analyte in the mobile phase. A compound that is poorly soluble in the initial mobile phase composition can cause precipitation or peak distortion.

Molecular Weight

The molecular size determines the optimal pore size and particle structure of the column.

●Small molecules (<5 kDa) perform well with standard pore sizes (60–120 Å) and 3–5 µm particles.

●Larger biomolecules (>50 kDa), such as peptides, proteins, or oligonucleotides, require wide-pore columns (≥300 Å) to allow sufficient mass transfer and interaction with the stationary phase.

If the pore size is too small, large molecules cannot diffuse properly, resulting in poor peak shapes, low recovery, or irreproducible retention times.

●Tip: When working with biomolecules, also consider surface coverage and end-capping. Insufficient end-capping can cause unwanted secondary interactions with silanol groups, affecting peak symmetry.

Chemical Stability

Chemical stability of the stationary phase is crucial when your analyte or mobile phase conditions are aggressive.

●Silica-based phases are widely used but have limited pH stability (typically pH 2–8).

●For acidic or basic analytes, or when operating under extreme pH or high organic solvent concentrations, polymer-based, hybrid-silica, or core-shell columns provide better durability and reproducibility.

Tip: If your analyte contains metal-coordinating functional groups (like phosphates, carboxylates, or catechols), consider using a metal-free column or deactivated hardware to prevent peak tailing and adsorption loss

2. Separation Goals: Define What You Want to Achieve

Once you understand your sample, the next step is to clarify what you need to separate — purity control, impurity profiling, or structural differentiation.

Your separation goal determines the column efficiency, selectivity, and length required for optimal performance.

Complex Mixtures

When analyzing complex or multi-component samples, high column efficiency and longer columns are essential for peak resolution.

●Columns with >10,000–20,000 theoretical plates (N) ensure sharper peaks and better baseline separation.

●A 250 mm column typically provides excellent resolution but requires longer analysis time and higher solvent consumption.

●For high-throughput workflows, UHPLC columns (50–100 mm, sub-2 µm particles) can deliver comparable resolution in minutes due to improved mass transfer and reduced band broadening.

Tip: Use a gradient elution program to improve separation of analytes with wide polarity differences, reducing total run time without sacrificing resolution.

Isomer or Chiral Separation

When separating structural or optical isomers, selectivity—not column length—is the deciding factor.

●Phenyl or PFP (pentafluorophenyl) columns provide strong π–π and dipole interactions, enhancing selectivity for aromatic and positional isomers.

●For enantiomeric separation, use chiral stationary phases (CSPs) such as cyclodextrin, polysaccharide-based, or macrocyclic glycopeptide columns, optimized for your target compound’s chirality and functional groups.

●Tip: Chiral separations are highly method-dependent; solvent composition, pH, and temperature must be optimized to achieve baseline resolution.

Speed vs Resolution

Every separation is a balance between speed, resolution, and back pressure.

●For routine QC testing or process monitoring, shorter columns (50–100 mm) or core–shell particles (2.6–3.0 µm) provide high efficiency with moderate pressure—ideal for fast, repeatable runs.

●For research-level or trace analysis, longer columns (150–250 mm) with smaller particle sizes (<3 µm) maximize resolution and sensitivity.

● Tip: Consider system compatibility — UHPLC systems can handle pressures up to 15,000 psi, while conventional HPLC instruments typically tolerate 6,000–9,000 psi.

3. Mobile Phase Conditions: Chemistry Meets Stability

Even the most advanced column can fail if your mobile phase doesn’t match its chemistry. The pH, organic solvent ratio, and buffer composition can dramatically affect both separation quality and column lifetime. Understanding these interactions helps maintain reproducibility and prolong column usability.

pH Range

The column must withstand your operating pH conditions.

● For acidic environments (pH 0.5–3), use acid-resistant columns such as uHPLCs USHD C18-AR, which provides stable performance across a wide pH range (0.5–8) and resists silica dissolution.

● For neutral to basic pH systems (pH 7–10), hybrid-silica or polymer-based columns offer excellent resistance to hydrolysis and maintain stable retention without phase degradation.

Tip: Always equilibrate the column thoroughly when changing pH to avoid sudden chemical stress that may shorten its lifespan.

Organic Solvent Ratio

Operating at high organic content (>90%)—for example, in gradient elution or HILIC methods—can lead to stationary phase collapse or dewetting in traditional silica columns.

Use solvent-resistant stationary phases, like the USHD series, which maintain bonded phase integrity, surface wetting, and reproducibility even under extreme solvent conditions.

Solvent Compatibility

Not all stationary phases tolerate every solvent equally. Before switching between solvents (e.g., methanol ↔ acetonitrile or to more aggressive ones like THF or IPA), confirm compatibility in the manufacturer’s specification.

Incompatible solvents can cause phase swelling, siloxane bond cleavage, or phase bleeding, ultimately reducing column efficiency and lifetime.

Best practice: Flush the column thoroughly with an intermediate miscible solvent before major solvent changes.

4. System Compatibility: The Often-Overlooked Dimension

Even the best column can’t perform at its peak if your system isn’t properly matched. System compatibility—covering pressure limits, column dimensions, and hardware connections—is the foundation for reliable and reproducible chromatography.

Pressure Limits

Column performance is directly linked to system pressure capacity.

● UHPLC systems (6,000–15,000 psi) are designed for columns with sub-2 µm particles, providing ultra-fast separations with superior resolution.

● Conventional HPLC systems (≤4,000 psi) work best with 3–5 µm particles to avoid overpressure and pump stress.

Before installing a new column, always verify the maximum pressure rating of both the column and the instrument. Exceeding these limits can cause leaks, void formation, or even column damage.

Pro tip: Keep system backpressure below 80% of the instrument’s limit to ensure long-term stability.

Column Inner Diameter (ID)

The column’s internal diameter directly affects flow rate, detection sensitivity, and loading capacity.

● 2.1–4.6 mm ID – Standard for analytical separations, balancing sensitivity and robustness.

● 10–50 mm ID – Ideal for preparative and semi-preparative scales, allowing larger sample injections and higher flow rates.

● ≤1.0 mm ID – Used in micro- or capillary HPLC systems where sample quantity is limited and high sensitivity is required.

Smaller IDs improve mass sensitivity but demand precise control of flow rate and injection volume to maintain reproducibility.

Hardware and Interface

Compatibility extends beyond pressure and dimensions—hardware fittings and tubing also matter.

● Ensure all connections (fittings, ferrules, tubing ID) match your system’s design to prevent dead volume, leaks, and peak distortion.

● Use low-dead-volume (LDV) fittings for high-efficiency columns, especially in UHPLC systems.

Neglecting these details can easily compromise peak shape and reproducibility, even when chemistry is perfect.

Conclusion: A Structured Path to Reliable Results

Selecting an HPLC column is not just about picking the most popular brand or the longest column—it’s about understanding your system and sample holistically.

By evaluating your needs across these four dimensions—sample properties, separation goals, mobile phase conditions, and system compatibility—you create a logical, repeatable framework for column selection.

This four-dimensional approach ensures you’re not just guessing—you’re making a technically informed decision that improves performance, stability, and reproducibility.

And remember, if you’re unsure, consult professional column manufacturers. For example, USHD C18-AR series offers exceptional acid resistance (pH 0.5–8), solvent stability, and UHPLC-level efficiency, making it a versatile solution for both research and production environments.

The right column doesn’t just separate your sample—it separates good analysis from great analysis.

Ready to elevate your chromatography results? Visit our website at uhplcs.com to explore the full lineup of uHPLCs high‑performance columns, including the USHD C18‑AR series. Our technical team is standing by to help you select the perfect column for your sample, system and separation goals. Don’t settle for “good” — let’s achieve great analysis together.